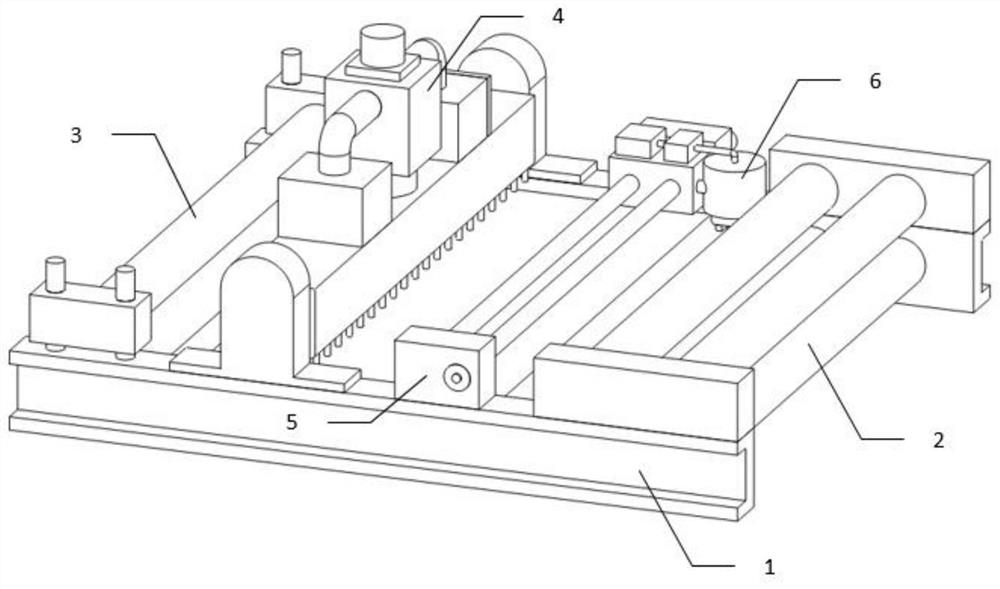

Photovoltaic bottom plate dust and rust removing device and using method thereof

A bottom plate, photovoltaic technology, applied in the cleaning method using tools, the cleaning method using gas flow, cleaning method and utensils, etc., can solve the problems of complicated operation, unfavorable assembly line, difference in cleaning effect, etc., to improve the surface quality, improve the Use efficiency and strengthen the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0043] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of the structure, change of the proportional relationship or adjustment of the size shall still fall within the scope of the technical content disclosed in the present invention without affecting the effect and the purpose of the present invention. within the scope covered.

[0044] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the...

Embodiment

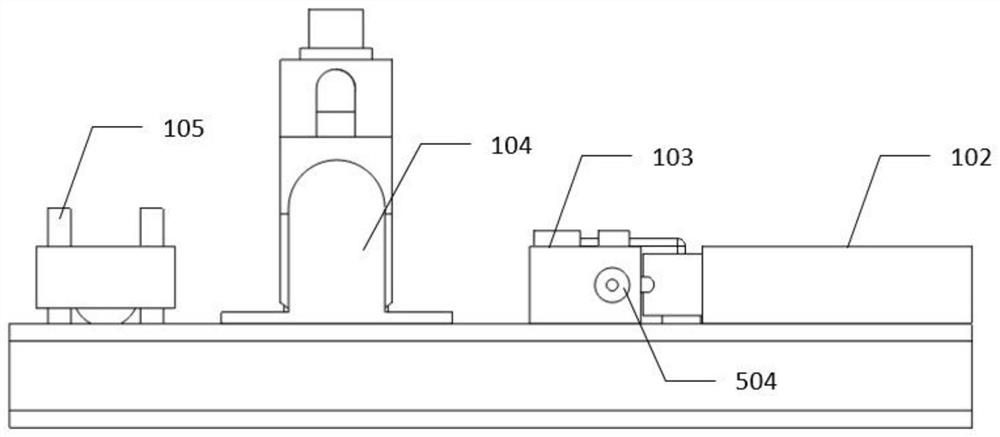

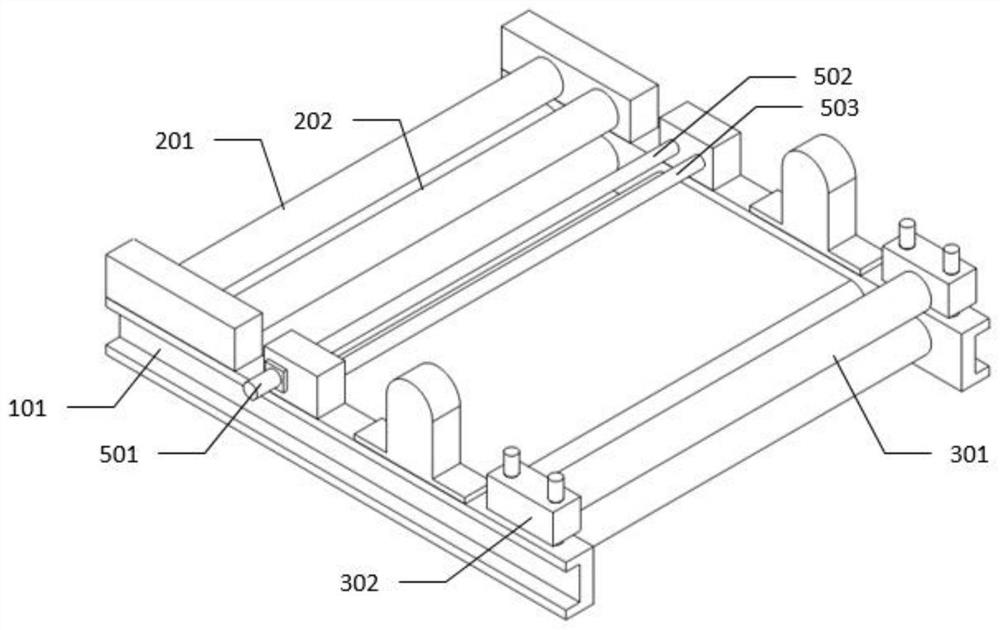

[0059] The photovoltaic bottom plate is transported from right to left. The first pressing roller 201 and the first pressing roller 201 in the pressing roller assembly 2 are in the form of active rotation. The bottom plate realizes the function of extruding and transporting.

[0060] After the distance sensor 605 detects the photovoltaic backplane, the controller 7 drives the first motor 407 , the second motor 501 , the laser 601 and the vibrating mirror controller 604 to turn on.

[0061] The laser 601 in the derusting assembly 6 generates a light source, the coupler 602 and the transmission fiber 603 both improve the utilization efficiency of the light source, and the vibrating mirror controller 604 in the concentrator 607 can adjust the focus of the laser gun head 606 .

[0062] The dust removal component 4 adsorbs the dust and rust residue on the surface of the photovoltaic base plate, and the first motor 407 drives the rotating member 406 to rotate at a high speed so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com