Fe-doped ZnO nano-film as well as preparation method and application thereof

A nano-film and thin-film technology, applied in chemical instruments and methods, catalyst activation/preparation, water treatment of special compounds, etc., can solve the problem of lack of inhibition of photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

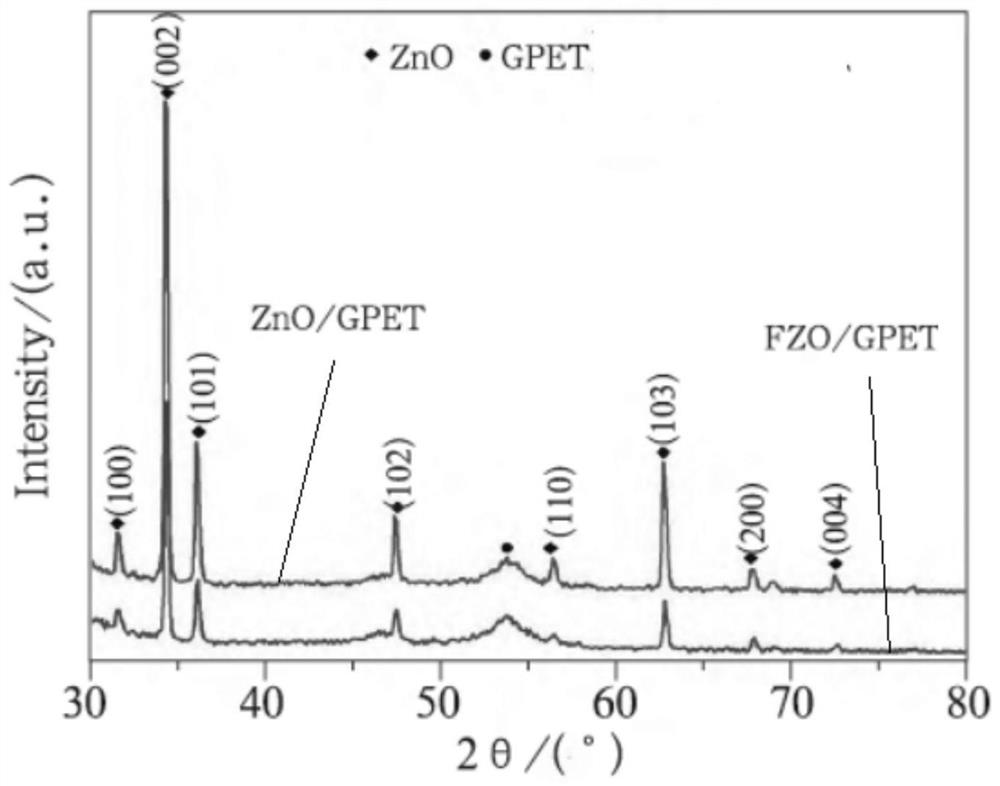

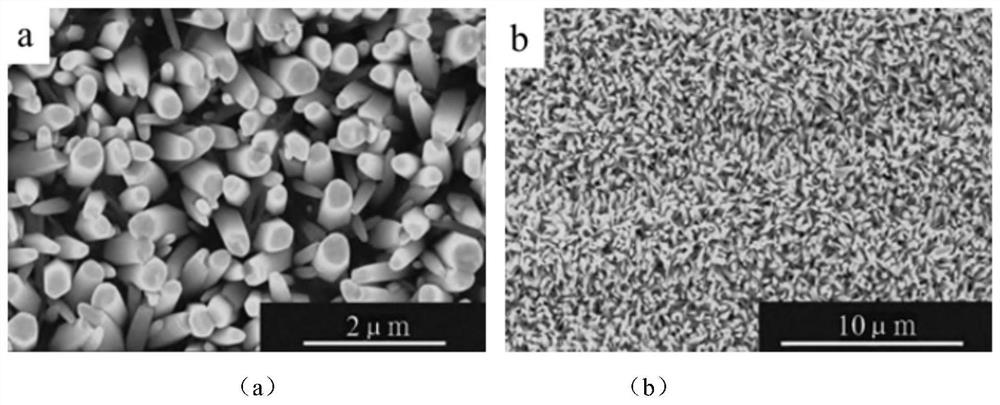

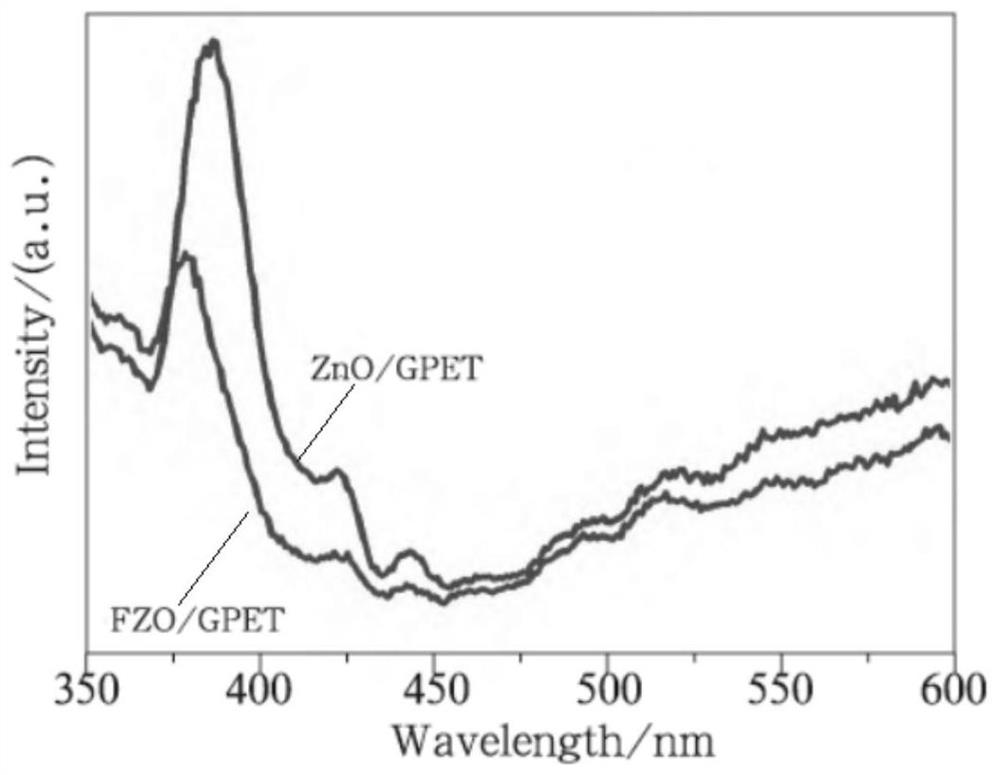

[0034] The preparation method of Fe-doped ZnO nano film provided by the invention comprises the following steps:

[0035] The first step is to clean the GPT flexible substrate. Cut the GPT flexible substrate into a square of 1.5cm×1.5cm. After ultrasonic cleaning with acetone (10min) and ethanol (10min), take it out and transfer it to deionized water. Clean with ultrasonic waves for 10 minutes, then take out the GPT flexible substrate, put it in an oven, and dry it at 70°C for later use.

[0036] The second step is to coat the seed crystal layer: deposit the ZnO seed layer (30nm) on the substrate by using a radio frequency magnetron sputtering device (high-purity Zn as the target) on the GPT flexible substrate that has been dried and prepared, and the sputtering time is 3 to 5 minutes. , the sputtering current is 6-10mA, the sputtering is in a vacuum environment, and the vacuum degree is 8-10Pa.

[0037] Preparation of the third step precursor solution: adding hexamethylenete...

Embodiment 1

[0049] 1) Plating a ZnO seed layer on the surface of the GPT substrate with an ion sputtering coater, with a pressure of 10 Pa and a current of 6 mA for 1 min, and a current of 8 mA for 4 min;

[0050] 2) Prepare the precursor solution, Zn(NO 3 ) 2 ·6H 2 O, HMT and Fe(NO 3 ) 3 9H 2 The molar ratio of O is 1:1:1, Zn(NO 3 ) 2 ·6H 2 The molar concentrations of O and HMT are both 0.05mol / L, Fe(NO 3 ) 3 9H 2 The molar concentration of O is 0.05mol / L, and the magnetic stirrer stirs for 20min;

[0051] 3) The obtained precursor solution was transferred to a 40 mL airtight PTFE-lined stainless steel autoclave. Then, the GPT substrate with ZnO seed layer deposited was vertically immersed in the precursor solution, and then placed in an oven at a constant temperature of 95 °C for 6 h, cooled to room temperature naturally, then taken out, washed repeatedly with distilled water and absolute ethanol, and dried at 60 °C. After drying for 1 h at °C, take it out to obtain a sample...

Embodiment 2

[0053] 1) Plating a ZnO seed layer on the surface of the GPT substrate with an ion sputtering coater, with a pressure of 10 Pa and a current of 6 mA for 1 min, and a current of 8 mA for 4 min;

[0054] 2) Prepare the precursor solution, Zn(NO 3 ) 2 ·6H 2 O, HMT and Fe(NO 3 ) 3 9H 2 The molar ratio of O is 1:1:2, Zn(NO 3 ) 2 ·6H 2 The molar concentrations of O and HMT are both 0.05mol / L, Fe(NO 3 ) 3 9H 2 The molar concentration of O is 0.1mol / L, and the magnetic stirrer stirs for 20min;

[0055] 3) The obtained precursor solution was transferred to a 40 mL airtight PTFE-lined stainless steel autoclave. Then, the GPT substrate with ZnO seed layer deposited was vertically immersed in the precursor solution, and then placed in an oven at a constant temperature of 95 °C for 6 h, cooled to room temperature naturally, then taken out, washed repeatedly with distilled water and absolute ethanol, and dried at 60 °C. After drying for 1 h at °C, take it out to obtain a sample....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com