Joint for carbon fiber composite arm section and preparation method of joint

A composite material and carbon fiber technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of unreasonable force transmission design, general surface quality control, single molding method, etc., to solve the problems of strength and manufacturing. Conflict between, resolve the contradiction between strength and weight, ensure the effect of connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

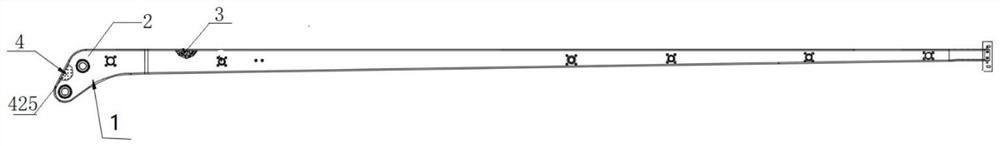

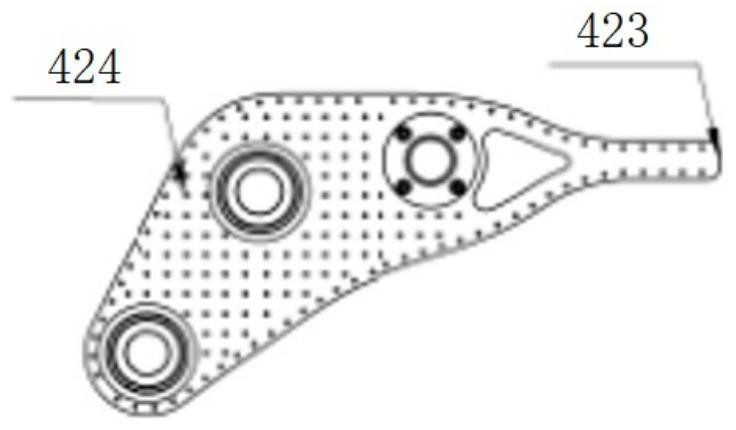

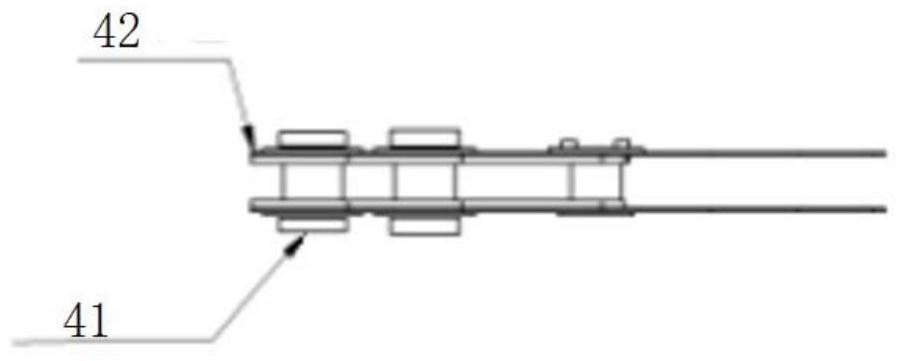

[0047] Such as figure 1 As shown, it is a carbon fiber composite material arm section, and the large end of the carbon fiber composite material arm section is a joint 1 for a carbon fiber composite material arm section of this embodiment, including: a carbon fiber composite material joint shell 2, and a joint inner core 3 , The end is connected to the embedded part 4. The joint inner core 3 is filled in the interior of the carbon fiber composite material joint shell 2; the end connection embedded part 4 is arranged at the end of the carbon fiber composite material joint shell 2, and is embedded in the joint inner core for The connection of the large end of a carbon fiber composite boom section to another boom section or a hydraulic device.

[0048] When the carbon fiber composite jib joint of this embodiment is used, the large end of the jib joint is connected to the small end of the previous jib joint through the end connection embedded part 4 of the joint. The carbon fiber...

Embodiment 2

[0069] The preparation method of the carbon fiber composite arm section described in this example, the preparation steps and the size of the arm section are the same as those in Example 1, the difference is that the autoclave forming process is used for forming in step S4, and the The resin transfer molding process is the RTM process for molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com