Vacuum annealing method for magnetic material

A magnetic material and annealing technology, which is applied in the field of vacuum annealing of magnetic materials, can solve the problems of unqualified coercive force and large deformation of magnetic properties, and achieve the effects of improving magnetic induction intensity, shortening processing time, and green and clean production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

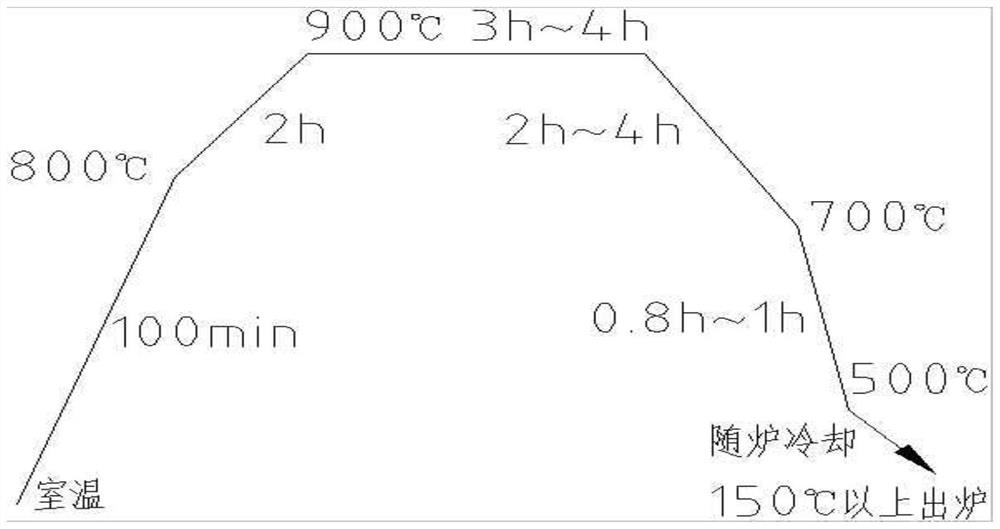

[0025] The invention is a vacuum annealing method for magnetic materials. The purpose of the magnetic annealing of electromagnetic pure ferromagnetic is to eliminate the deformation internal stress through the magnetic annealing, to complete the recrystallization process of the matrix, and to make the crystal grain grow sufficiently to obtain high electromagnetic properties. The metallographic structure of high electromagnetic performance is equiaxed, large grain and uniform ferrite structure. Small or uneven grain size will have a greater impact on the coercive force, and the size and uniformity of the grain size are affected by the holding temperature and the heating and cooling speed. Therefore, the heat treatment process is also very important to reduce the coercive force of electromagnetic pure iron. The difference in heating rate and cooling rate directly affects the grain size of the recrystallization magnetic annealing of the material, that is, the texture of the grain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com