A 3D-printed mechanical bionic auricular cartilage tissue engineering scaffold and its manufacturing method

A 3D printing, cartilage tissue technology, used in tissue regeneration, medical science, additive processing, etc., to save printing materials, reduce support structures, and have excellent printability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Use 123D Design 2.2.14 to design a cube model of 8mm×8mm×3mm, choose a PLCL-PCL blend with a ratio of 90:10 as the raw material (CN201910139657.9), and print it by melt extrusion deposition (FDM). method, using a desktop 3D printer to print at 170°C, printing speed 2mm / s, and 70% filling conditions to obtain a cube model with a porous frameless structure, measure and print to obtain the actual three-dimensional size of the model, and according to the original model size data, The shrinkage rates on the X, Y and Z axes in 3D printing were calculated respectively, and the results were: length (X axis), 6.75% ± 0.51%; width (Y axis), 10.82% ± 0.43%; height (Z axis) ), 2.35%±0.73%.

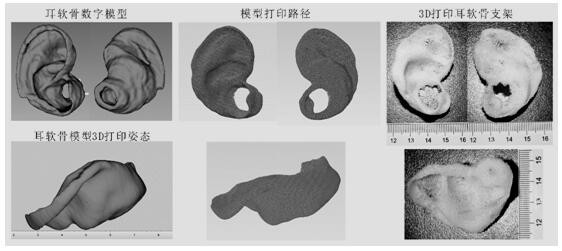

[0035] 2. In Materialise Magics 24.0, the acquired auricle cartilage scan file is converted into a digital model file and its contact angle with the horizontal plane is adjusted to maximize the contact area with the horizontal plane; according to the X, Y and Z calculated in step 1) The shr...

Embodiment 2

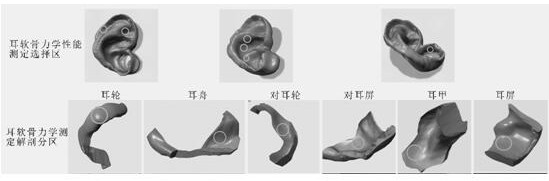

[0037] 1. In Magics 24.0, the digital model of the auricle cartilage adjusted in step 2) of Example 1 is divided into the digital model regions of the tragus, the antitragus, the helix, the antihelix, the concha and the auricular nave according to the anatomical structure. The maximum area of the cylindrical area with a flat structure that can be selected is used as a reference, and the digital model areas of the tragus, the antitragus, the helix, the antihelix, the concha and the nave are selected to meet the mechanical performance test requirements of the stent. . Based on the shrinkage results of the 90:10 PLCL-PCL blend 3D printing 70% filling rate cube scaffolds in the X, Y and Z axes, the digital model of the selected area was scaled and adjusted according to the above process and conditions 3D Print borderless porous scaffolds.

[0038] 2. The mechanical properties of the model bracket in the selected area of the mechanical test obtained by 3D printing in step 1) a...

Embodiment 3

[0040] 1. Use 123D Design 2.2.14 to design a cube model with a porous frameless structure of 8mm × 8mm × 3mm, select a PLCL-PCL blend with a ratio of 80:20 as the raw material, and print it by melt extrusion deposition (FDM). , use a desktop 3D printer to print the model at a filling rate of 70% at 170 ° C and a printing speed of 2 mm / s, measure and print the actual three-dimensional size of the model, and calculate the X in 3D printing according to the size data of the original model. The shrinkage rate on the three axes of , Y and Z, the results are: length (X axis), 6.75% ± 0.51%; width (Y axis), 10.82% ± 0.43%; height (Z axis), 2.35% ± 0.73% .

[0041] 2. In Magics24.0, the acquired auricle cartilage scan file is converted into a digital model file and its contact angle with the horizontal plane is adjusted to maximize the contact area with the horizontal plane; according to the X, Y and Z three calculated in step 1) The shrinkage rate results on the axis, after scaling a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com