High-thermal-conductivity and low-thermal-expansion brake lining and preparation method thereof

A brake lining and low thermal expansion technology, which is applied in friction linings, chemical instruments and methods, mechanical equipment, etc., can solve the problems of inconvenient traceability and error-prone ingredients, and achieve strong traceability, convenient ingredients, and high performance. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares the brake lining of the present invention

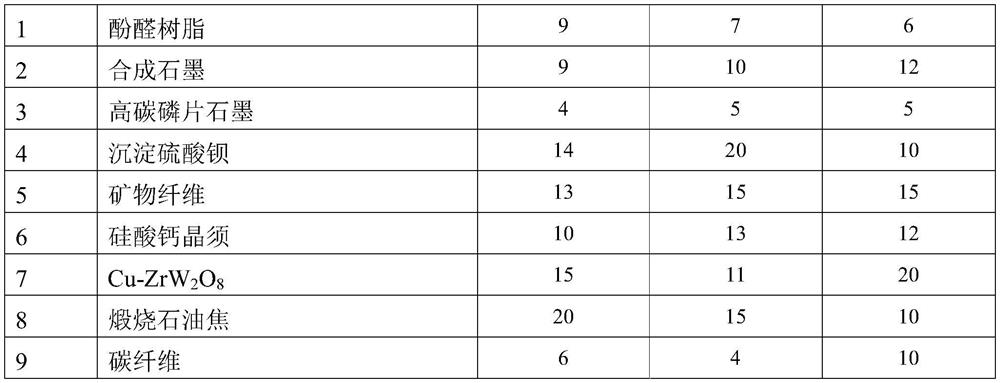

[0027] The formula ratio of the brake lining of the present invention of table 1

[0028]

[0029]

[0030] The brake lining of the present invention is processed according to the steps of raw material mixing, pressing, heat treatment, and grinding, and the specific preparation method is as follows:.

[0031] (1) Raw material mixing: carbon fiber, Cu-ZrW 2 o 8 Add 1 / 4 of the phenolic resin and 1 / 4 of the formula to the precipitated barium sulfate into the roller mixer, keep the speed of 240r / min, stir for 4min, and pre-mix; add the rest of the formula In the roller mixer, keep the speed of 450r / min, stir for 5min, and mix the materials evenly;

[0032] (2) Pressing: One-step molding method is adopted, the fabric and the bottom material are the same material, the hot pressing mold is the ejector mold, the lower layer is the raw material, and the upper layer is the steel back; the control temperatu...

Embodiment 2

[0041] Embodiment 2 verifies the performance of the brake lining of the present invention

[0042]The present invention uses the brake lining prepared by the formulas of Examples 1 to 3, commercially available products and two groups of controls to conduct experiments to investigate the thermal expansion and friction coefficient of the brake lining. Among them, there is no carbon fiber in the formula of Comparative Example 1, and the other groups Distribution and consumption are identical with embodiment 1, do not have Cu-ZrW in the prescription of comparative example 2 2 o 8 , other components and consumption are identical with embodiment 1.

[0043] The experimental procedures of thermal expansion and friction coefficient are carried out according to B5763-2008, and the specific results are shown in Table 2 and 3:

[0044] Table 2 Thermal Expansion Experimental Results

[0045]

[0046] It can be seen from Table 2 that the 5 points on each sample were tested according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com