Shield dispersant and its preparation method and application

A technology of dispersant and ceramic dispersant, which is applied in the field of shield dispersant and its preparation, can solve the problems of easily damaged equipment, low dispersibility and high corrosion of shield cutter head, etc., and achieves the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

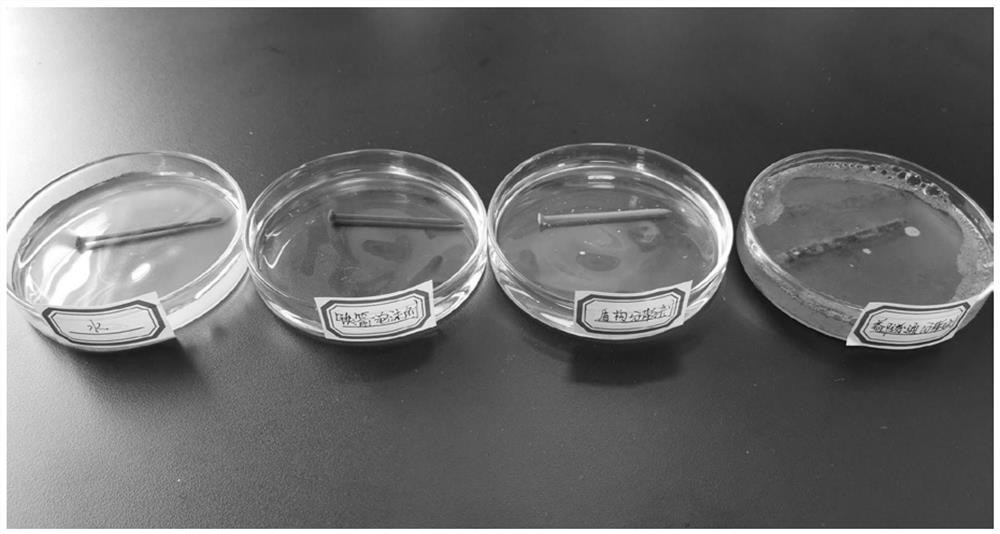

Image

Examples

preparation example Construction

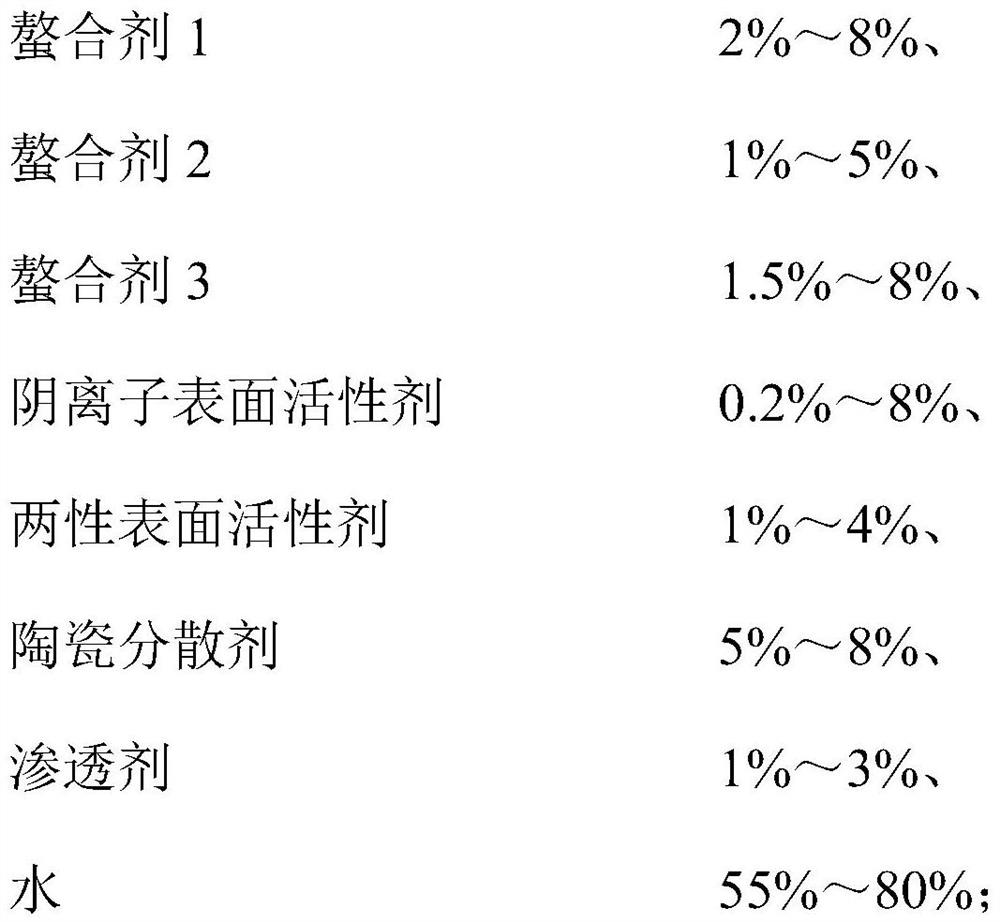

[0068] The present invention also provides a kind of preparation method of above-mentioned shield dispersant, comprises the following steps:

[0069] The chelating agent 1, chelating agent 2, chelating agent 3, anionic surfactant, amphoteric surfactant, ceramic dispersant, penetrating agent and water are mixed.

[0070] Preferably, when some raw materials are difficult to dissolve, it is necessary to dissolve and then mix to prepare a shield dispersant that is uniform, stable, and has a good dispersion effect. The preparation method includes the following steps:

[0071] Under the condition of 60-70°C and stirring, mix 10%-40% water and chelating agent 1-3 evenly to prepare mixture A;

[0072] Under the condition of stirring at 40-60°C, 25%-45% of water, amphoteric surfactant, ceramic dispersant and penetrating agent are uniformly mixed to prepare mixture B;

[0073] Then, in a stirring state, mix the mixture A and the mixture B uniformly to prepare the mixture C;

[0074] U...

Embodiment 1

[0092] This embodiment provides a shield dispersant and its preparation method.

[0093] (1) By mass percentage, the composition of shield dispersant 1 is as follows:

[0094]Sodium citrate 5%, ethylenediaminetetraacetic acid (EDTA) 2%, sodium tripolyphosphate 2.5%, sodium pyrophosphate 2%, sodium lauryl sulfate (K12) 2%, alpha-olefin sulfonate sodium (AOS ) 0.5%, cocamidopropyl betaine (CAB-35) 2%, ceramic dispersant 8%, penetrant 2%, water 74%.

[0095] (2) Prepare shield dispersant 1:

[0096] Set the temperature of the stainless steel mixing tank 1 to 60°C, add 30% water to the mixing tank 1, add sodium citrate, ethylenediaminetetraacetic acid, sodium tripolyphosphate and sodium pyrophosphate while stirring, and stir until uniform, Prepare mixture A;

[0097] Set the temperature of the stainless steel stirring tank 2 to 50°C, add 30% water to the stirring tank 2, add cocamidopropyl betaine, ceramic dispersant and penetrating agent while stirring, stir until uniform, and...

Embodiment 2

[0104] This embodiment provides a shield dispersant and its preparation method.

[0105] (1) By mass percentage, the composition of shield dispersant 1 is as follows:

[0106] Sodium citrate 3.7%, disodium ethylenediaminetetraacetic acid (EDTA-2Na) 2.3%, sodium tripolyphosphate 1.3%, sodium lauryl sulfate (K12) 2.4%, alpha-olefin sulfonate sodium (AOS) 2.8 %, cocamidopropyl betaine (CAB-35) 3%, ceramic dispersant 6%, penetrant (JFC-2) 1.2%, sodium chloride 2.3%, water 75%.

[0107] (2) Prepare shield dispersant 2:

[0108] Set the temperature of the stainless steel stirring tank 1 at 60°C, add 30% water to the stirring tank 1, and add sodium citrate, disodium edetate, sodium tripolyphosphate, sodium pyrophosphate and chloride while stirring. Sodium, stirred until uniform, prepared mixture A;

[0109] Set the temperature of the stainless steel stirring tank 2 to 50°C, add 30% water to the stirring tank 2, add cocamidopropyl betaine, ceramic dispersant and penetrating agent w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com