Low-density waterproof elastic two-component sealant

A sealant, low-density technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve problems such as the bonding of concrete pipe fittings, and achieve outstanding water resistance, good water resistance and good thixotropy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

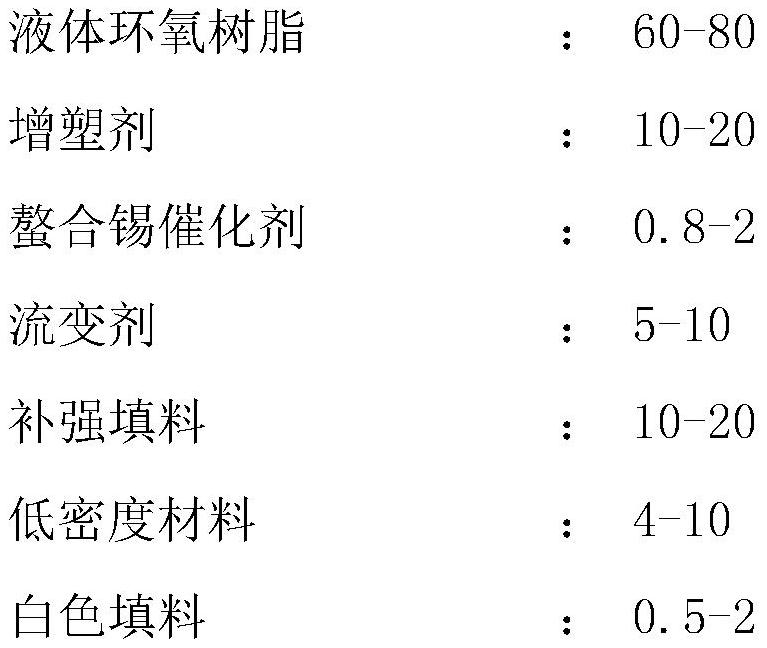

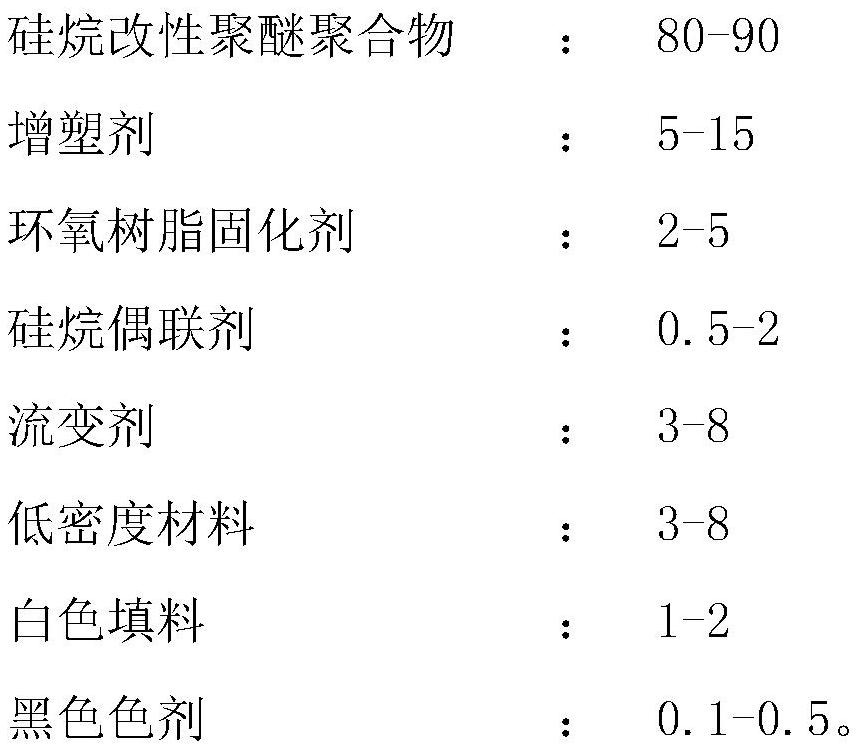

Method used

Image

Examples

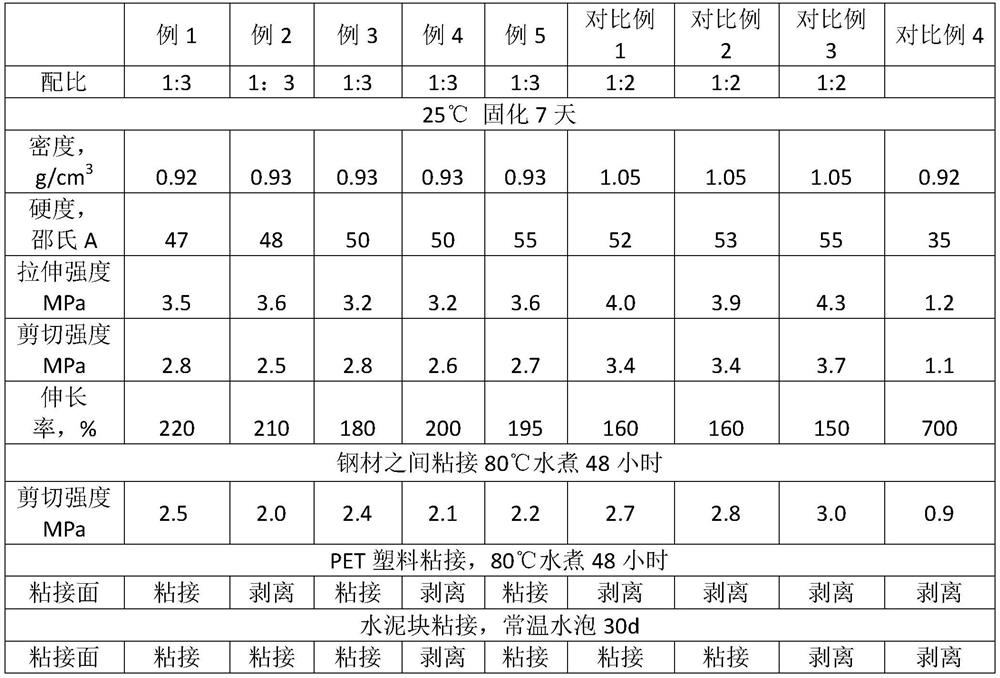

Embodiment 1

[0036] Put 600 grams of BE-188 liquid epoxy resin, 100 grams of dioctyl adipate, and 15 grams of KAT225 chelated tin catalyst into a 2L double planetary stirring tank, mix for 5 minutes until uniform, and then add 50 grams of 150 silicon gas , after high-speed dispersion until uniform, then add 170 grams of nano-calcium carbonate, 15 grams of titanium dioxide, 50 grams of 4038H type glass beads, after mixing evenly, the discharge is the A1 component of the sealant.

[0037] Add 800 grams of S327 silane-modified polyether polymer, 100 grams of dioctyl adipate, 25 grams of K-54, and 10 grams of aminoethylaminopropyltrimethoxysilane into a 2L double planetary stirred tank In the process, mix for 10 minutes until uniform, add 40 grams of 150 gas silicate, disperse at high speed until uniform, then add 25 grams of 4038H glass microspheres, 1 gram of black colorant, mix uniformly and vacuum for 10 minutes, and the material is B1 group point.

Embodiment 2

[0039] Put 600 grams of BE-188 liquid epoxy resin, 100 grams of dioctyl adipate, and 15 grams of KAT225 chelated tin catalyst into a 2L double planetary stirring tank, mix for 5 minutes until uniform, add 50 grams of 150 gas silicon, After dispersing at high speed until uniform, add 170 grams of nano-calcium carbonate, 15 grams of titanium dioxide, and 50 grams of 4038H glass microspheres. After mixing evenly, the output is the A2 component of the sealant.

[0040] Add 800 grams of SAT350 silane-modified polyether polymer, 100 grams of dioctyl adipate, 25 grams of K-54, and 10 grams of aminoethylaminopropyltrimethoxysilane into a 2L double planetary stirring tank In the process, mix for 10 minutes until uniform, add 40 grams of 150 fumed silicon, disperse at high speed until uniform, then add 25 grams of 4038H empty glass beads, 1 gram of black colorant, mix uniformly and vacuum for 10 minutes, and the material is B2 components.

Embodiment 3

[0042] Put 600 grams of BE-188 liquid epoxy resin, 100 grams of dioctyl adipate, and 15 grams of KAT225 chelated tin catalyst into a 2L double planetary stirring tank, mix for 5 minutes until uniform, add 50 grams of 150 gas silicon, After dispersing at high speed until uniform, add 170 grams of nano-calcium carbonate, 15 grams of titanium dioxide, and 50 grams of 4038H type glass beads. After mixing evenly, the output is the A3 component of the sealant.

[0043] Add 800 grams of S327 silane-modified polyether polymer, 100 grams of dioctyl adipate, 25 grams of K-54, and 10 grams of aminoethylaminopropylmethyldimethoxysilane into a 2L In a double planetary stirring tank, mix for 10 minutes until uniform, add 40 grams of 150 gas silicon, and disperse at a high speed until uniform, then add 25 grams of 4038H glass microspheres, 1 gram of black colorant, mix uniformly for 10 minutes in a vacuum, and then discharge. It is the B3 component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com