Hot air device for drying bentonite additives

A technology of hot air device and additives, which is applied in the direction of drying gas arrangement, drying solid materials, lighting and heating equipment, etc., which can solve the problems of tediousness and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

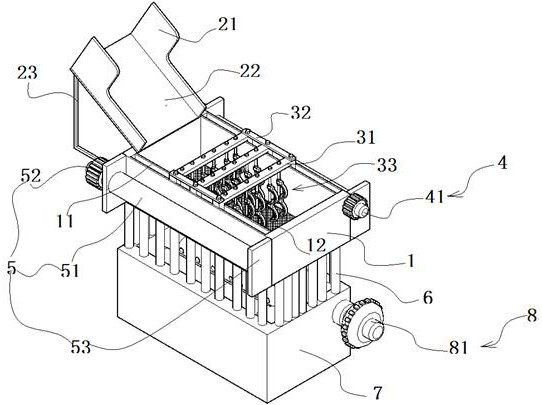

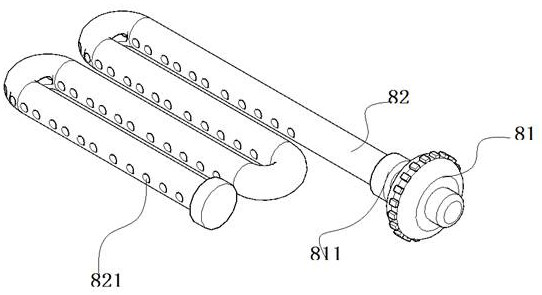

[0048] Such as Figure 1-5 As shown, a hot air device for drying bentonite additives includes a crushed material bin 1 having a crushed material cavity, and a metal screen 12 is provided at the bottom of the crushed material cavity.

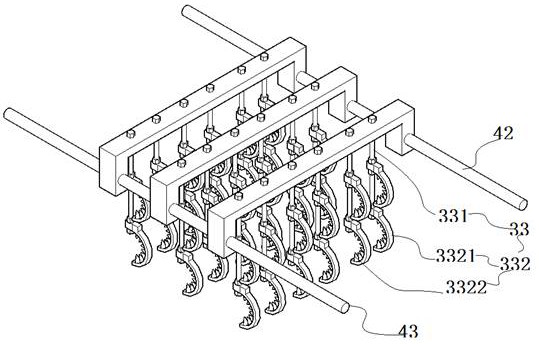

[0049] The above-mentioned hot air device for drying the bentonite additive also includes a scrap assembly sliding in the scrap bin 1; the scrap assembly is used for scrapping the bentonite additive into the scrap cavity, and the bentonite additive is broken by the scrap assembly.

[0050] In order to realize fast feeding of crushed materials, the above-mentioned hot air device for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com