Thermal comfort PM2.5-proof nanofiber mask filter element and preparation method thereof

A technology of nanofibers and thermal comfort, which is applied in the field of nanofiber mask filter element and its preparation, can solve the problems that have not been applied, and the hot feeling of human body face has not been considered, and achieve the effect of simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

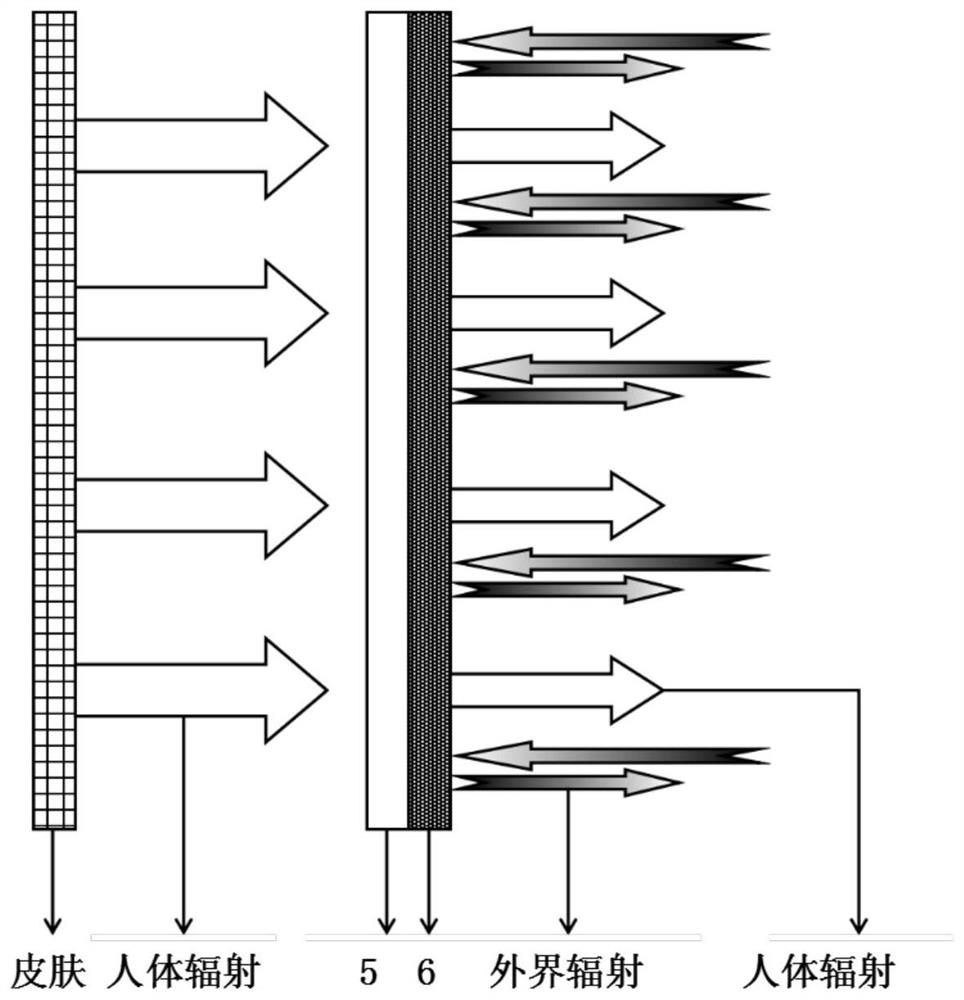

Problems solved by technology

Method used

Image

Examples

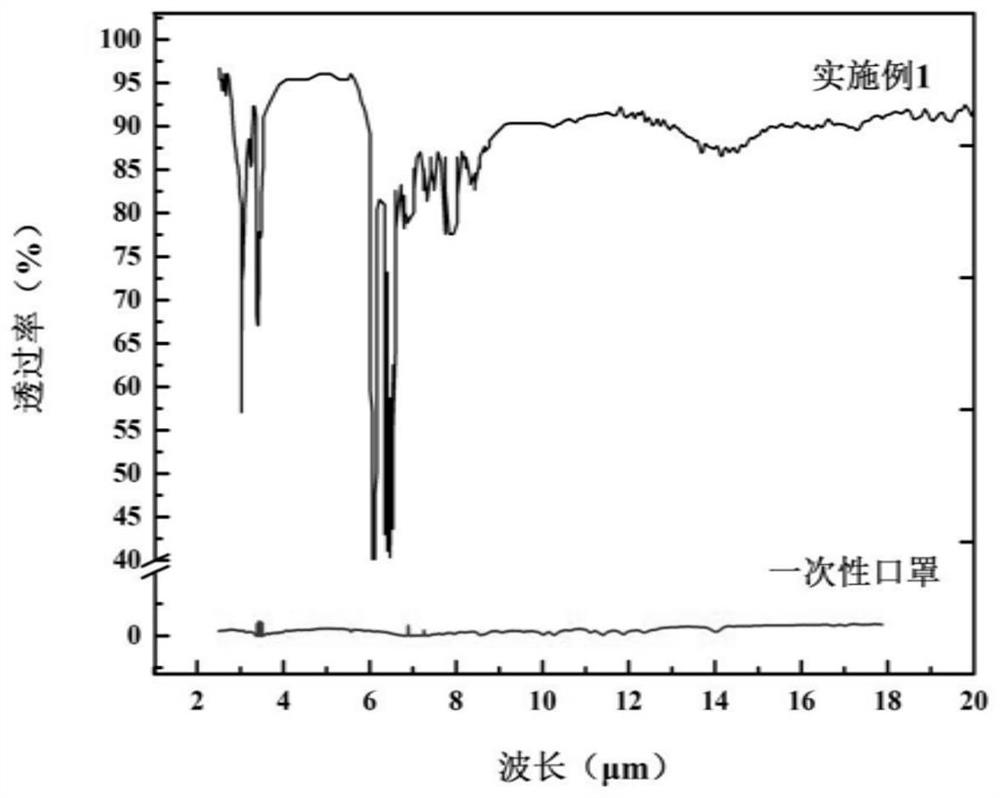

Embodiment 1

[0056] A thermal comfort anti-PM 2.5 The preparation method of the nanofiber mouth mask filter element, concrete steps are:

[0057] (1) Add 2g of polyamide 66 to 8g of formic acid and mix, stir evenly with a glass rod, pay attention to open the fume hood when taking formic acid; put 0.75g of zinc oxide (purity 99.5%, average particle size 20nm) in the above In the mixed solvent, vibrate with an ultrasonic oscillator for 1.5h, stir evenly to prepare solution A;

[0058] (2) Add spinning solution A to the injection system in the electrospinning device (see figure 1 ), figure 1 Including bolus injection system 1, injection system 2, electrostatic high voltage system 3 and receiving system 4. The receiving system was improved to a red copper mesh receiving plate, and the parameters of the electrospinning process were as follows: the receiving distance was 15cm, the electrostatic high voltage was 20KV, the injection speed was 0.1mm / min, the temperature was 35°C, and the relativ...

Embodiment 2

[0068] A thermal comfort anti-PM 2.5 The preparation method of the nanofiber mouth mask filter element, concrete steps are:

[0069] (1) Mix 1.2g of polyamide 6 and 8.6g of formic acid evenly, pay attention to wear a gas mask and open the fume hood when taking formic acid; put 0.12g of calcium fluoride in the above mixed solvent, and use an ultrasonic oscillator to vibrate for 1.5 h, stir evenly to prepare solution A;

[0070] (2) Add spinning solution A to the injection system in the electrospinning device (see figure 1 ), figure 1 Including bolus injection system 1, injection system 2, electrostatic high voltage system 3 and receiving system 4. The receiving system is improved to a red copper mesh receiving plate. The parameters of the electrospinning process are: the receiving distance is 10cm, the electrostatic high voltage is 25KV, the injection speed is 0.05mm / min, the temperature is 28°C, and the relative humidity is 35%. The time is 30min to obtain the nanofibrous ...

Embodiment 3

[0080] A thermal comfort anti-PM 2.5 The preparation method of the nanofiber mouth mask filter element, concrete steps are:

[0081] (1) Mix 1.87g polyacrylonitrile and 13.68g N,N-dimethylformamide evenly; place 0.15g magnesium fluoride in the above mixed solvent, vibrate with an ultrasonic oscillator for 1.5h, and stir evenly to prepare a solution A;

[0082] (2) Add spinning solution A to the injection system in the electrospinning device (see figure 1 ), figure 1 Including bolus injection system 1, injection system 2, electrostatic high voltage system 3 and receiving system 4. The receiving system is improved to a red copper mesh receiving plate. The parameters of the electrospinning process are as follows: the receiving distance is 20cm, the electrostatic high voltage is 20KV, the injection speed is 0.1mm / min, the temperature is 26°C, and the relative humidity is 50%. The time is 40min to obtain the nanofibrous membrane;

[0083] (3) Dry the membrane in a constant tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average fiber diameter | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Average fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com