Preparation method of medical surgical suture

A technique of surgical suture and silk thread, applied in the field of medical supplies, can solve the problems of low tensile strength and elongation, poor biocompatibility, incomplete absorption, etc., achieve high tensile strength, improve hydrophilicity and surface The degree of wetting, the effect of complete absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

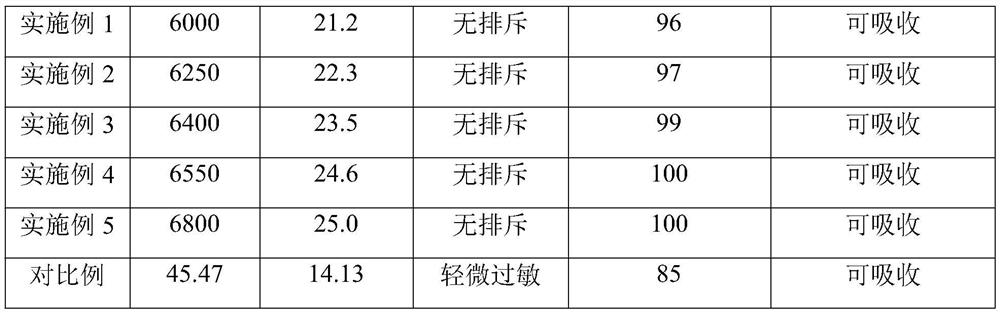

Examples

Embodiment 1

[0029] A medical surgical suture, which is composed of the following components by mass: 20 parts of 5-hydantoin acetic acid modified polylysine, 10 parts of polyethylene glycol hydroxy acid modified polylactic acid, sodium alginate based poly 45 parts of caprolactone copolymer, 10 parts of γ-cyclodextrin, 5 parts of hydroxybutyl methylcellulose.

[0030] The preparation method of the 5-hydantoin acetic acid modified poly-lysine comprises the following steps: dissolving 10 g of 5-hydantoin acetic acid in 100 g of methylene chloride to form a solution, and then adding 30 g of poly-lysine to the solution , 5g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 3g of 1-hydroxybenzotriazole, stirred and reacted at 60°C for 6 hours, and then evaporated to remove the solvent, And washed with ethanol and water for 3 times respectively, and then dried in a vacuum oven for 15 hours to obtain 5-hydantoin acetic acid modified polylysine.

[0031]The preparation method of the...

Embodiment 2

[0037] A medical surgical suture, which is composed of the following components by mass: 23 parts of 5-hydantoin acetic acid modified polylysine, 13 parts of polyethylene glycol hydroxy acid modified polylactic acid, sodium alginate based poly 48 parts of caprolactone copolymer, 13 parts of γ-cyclodextrin, 6 parts of hydroxybutyl methylcellulose.

[0038] The preparation method of the 5-hydantoin acetic acid modified poly-lysine comprises the following steps: dissolving 10 g of 5-hydantoin acetic acid in 115 g of ethyl acetate to form a solution, and then adding 35 g of poly-lysine to the solution , 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride 5g, 1-hydroxybenzotriazole 3g, stirred and reacted at 65°C for 6.5 hours, and then the solvent was removed by rotary evaporation, It was washed with ethanol and water for 4 times respectively, and then dried in a vacuum oven for 16 hours to obtain 5-hydantoin acetic acid-modified polylysine.

[0039] The preparation metho...

Embodiment 3

[0045] A medical surgical suture, which is composed of the following components by mass: 25 parts of 5-hydantoin acetic acid modified polylysine, 15 parts of polyethylene glycol hydroxy acid modified polylactic acid, sodium alginate based poly 50 parts of caprolactone copolymer, 15 parts of γ-cyclodextrin, 7 parts of hydroxybutyl methylcellulose.

[0046] The preparation method of the 5-hydantoin acetic acid modified poly-lysine comprises the following steps: dissolving 10 g of 5-hydantoin acetic acid in 130 g of dimethyl sulfoxide to form a solution, and then adding poly-lysine to the solution 40g, 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride 5g, 1-hydroxybenzotriazole 3g, stirred and reacted at 70°C for 7 hours, and then evaporated to remove the solvent , and washed with ethanol and water for 4 times respectively, and then placed in a vacuum drying oven for 17 hours to obtain 5-hydantoin acetic acid modified polylysine.

[0047] The preparation method of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com