Rotary wire peeling and tin-soldering equipment and method

A rotary and wire technology, applied in the direction of line/collector parts, electrical components, circuits, etc., can solve the problems of soldering flexibility, limited application range, large space occupation, etc., to save working space and wide application range , well-arranged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

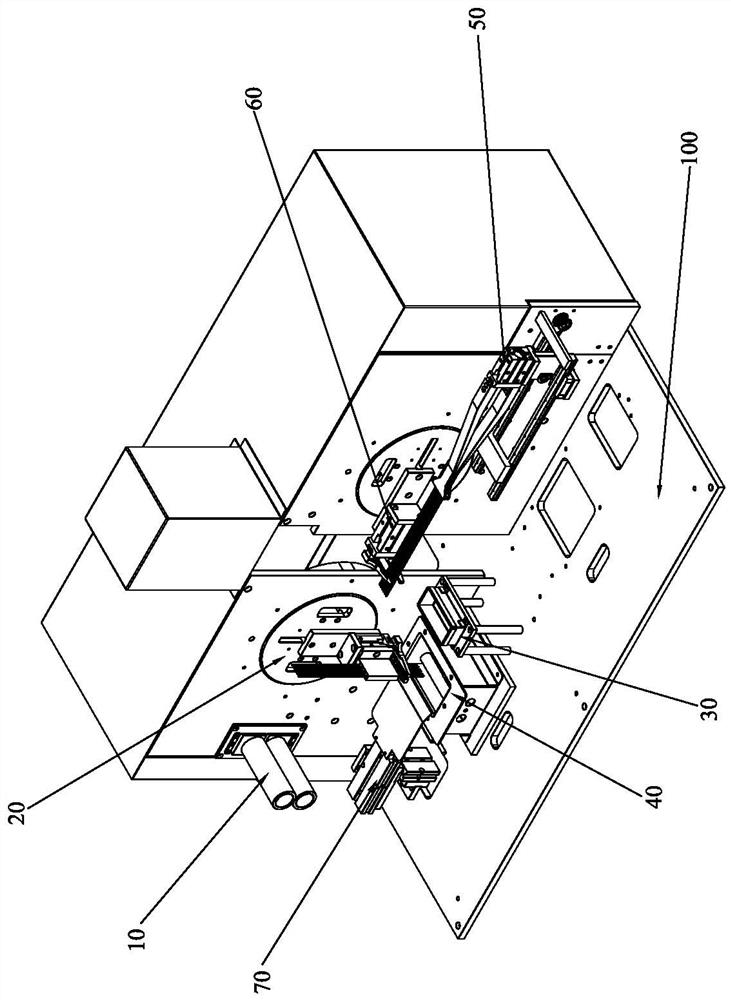

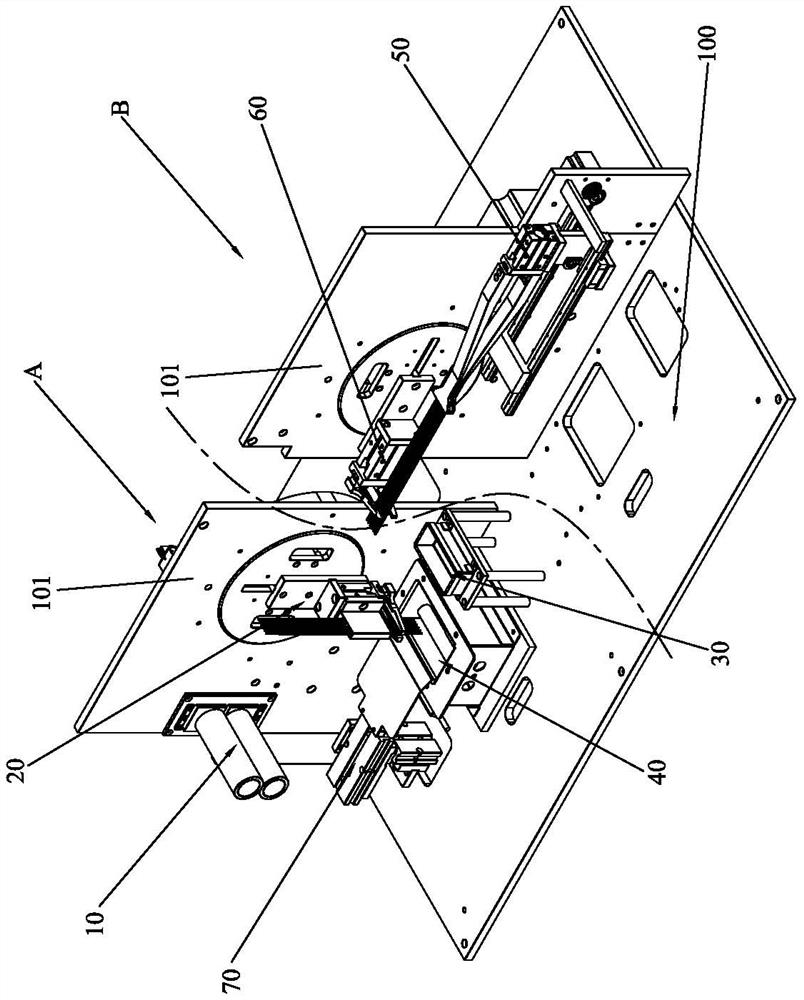

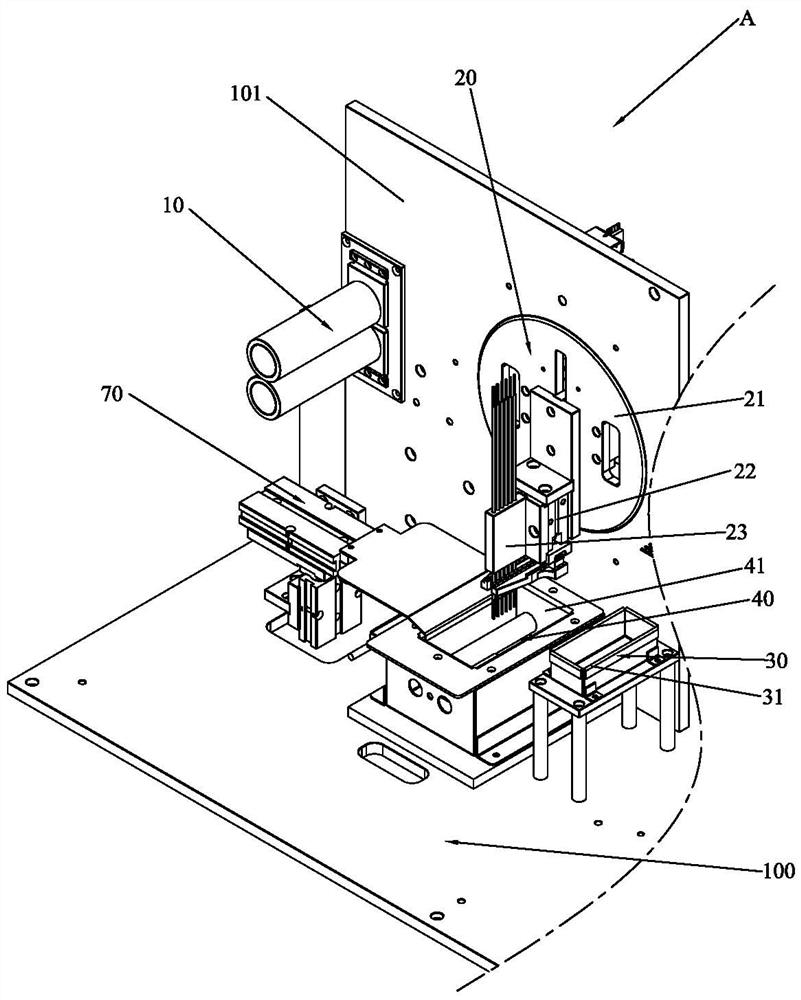

[0050] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the embodiment of the present invention.

[0051] A rotary wire peeling and soldering equipment, including a workbench 100 and a roller module 10 arranged on the workbench 100, a solder turntable module 20, a first flux tank module 30, a first tin furnace module 40, and a wire drawing module 50 , cutting module 60; Wherein:

[0052] The roller module 10 is used to smoothly feed the wire into the equipment, so that the soldering effect of the wire and the appearance quality of the wire can be improved;

[0053] The solder turntable module 20 has a turntable 21 and a first rotary driving device that drives the turntable 21 to rotate vertically around a horizontal axis. The device 22 is controlled by a lifting drive device to move up and down in the radial direction of the turntable 21; here, it can be detailed that: usually, the turntable 21 is provided with a ring gear (preferably arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com