Fe/Co-N-MCF composite catalyst for fuel cell and preparation method of Fe/Co-N-MCF composite catalyst

A composite catalyst and fuel cell technology, applied in the field of electrocatalysis, can solve the problem that the catalytic performance of ORR is not as good as that of platinum-based catalysts, achieve excellent methanol resistance and stability, meet the needs of large-scale production, and enhance the effect of ORR kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

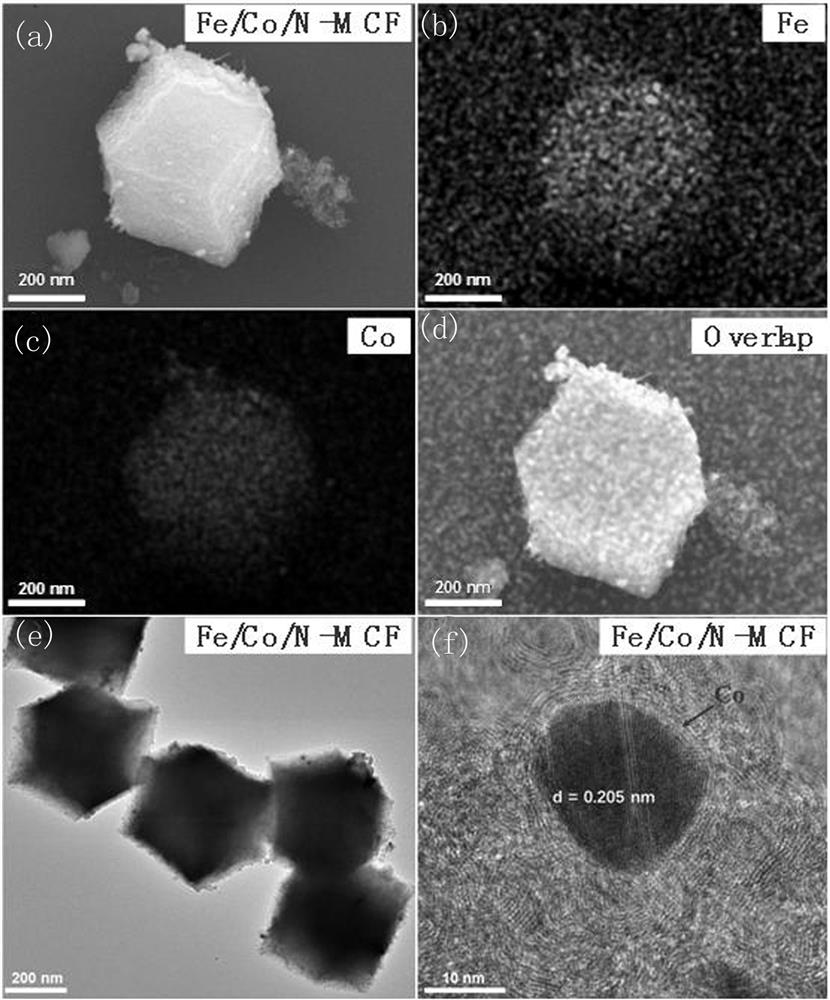

[0025] Example 1: A Fe / Co-N-MCF composite catalyst for fuel cells, using cobalt chloride hexahydrate and dimethylimidazole as raw materials to synthesize metal-organic framework ZIF-67, which was pyrolyzed under a nitrogen atmosphere to obtain nitrogen Doped Co-based mesoporous carbon framework Co-N-MCF; Co-N-MCF and ferric chloride solution were added to the high-gravity rotating packed bed, and the iron ions were uniformly adsorbed on Co-N-MCF. The composite catalyst Fe / Co-N-MCF for fuel cells can be obtained by pyrolysis again in nitrogen atmosphere.

[0026] The method for preparing Fe / Co-N-MCF composite catalyst for fuel cell, the steps are as follows:

[0027] (1) Dissolve 5 mmol (1.190g) of cobalt chloride hexahydrate and 40 mmol (3.284g) of dimethylimidazole in 100ml of methanol respectively, and add the methanol solution of cobalt chloride to the dimethyl In the methanol solution of imidazole, after reacting for 5min, let stand for 24h. The precursor ZIF-67 was prec...

Embodiment 2

[0034] Example 2: 0.05g of Co-N-MCF was added to 0.5 mol L -1 FeCl 3 solution, and then the mixed solution of the two was magnetically stirred, rotated for 10 minutes, then centrifuged, washed with deionized water for 3 times, and dried at 80° C. for 24 hours. The obtained product was heated to 750° C. at 5° C. / min for 2 hours under a nitrogen atmosphere, and sample 2 was obtained by pyrolysis. All the other preparation methods are with the method described in Example 1; the test method is with the method described in Example 1.

Embodiment 3

[0035] Example 3: ZIF-67 was heated to 750° C. at 5° C. / min for 2 hours under a nitrogen atmosphere, and Co-N-MCF was obtained by pyrolysis. The test method is as shown in Example 1.

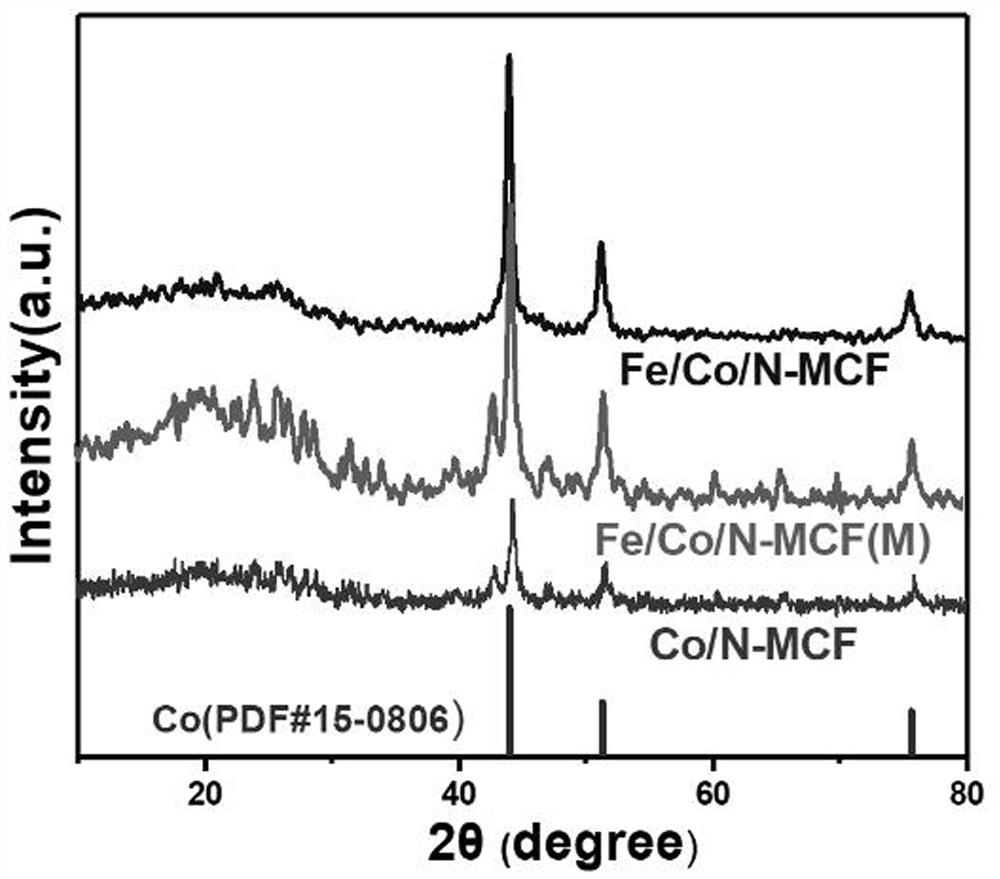

[0036] figure 2 The XRD patterns of the samples obtained in Example 1, Example 2 and Example 3, the Co / N-MCF diffraction peak obtained after pyrolysis is completely consistent with the diffraction peak of Co (PDF#15-0806), confirming that ZIF-67 The Co ions in can be transformed into Co nanoparticles at high temperature. However, no matter the subsequent high-gravity rotating packed bed strategy or the magnetic stirring method to load Fe onto Co / N-MCF, the obtained Fe / Co / N-MCF and Fe / Co / N-MCF(M) catalysts only obtained from The presence of Co nanoparticles was detected in the XRD pattern. This proves that the relatively low Fe content makes it difficult to form nanoparticles.

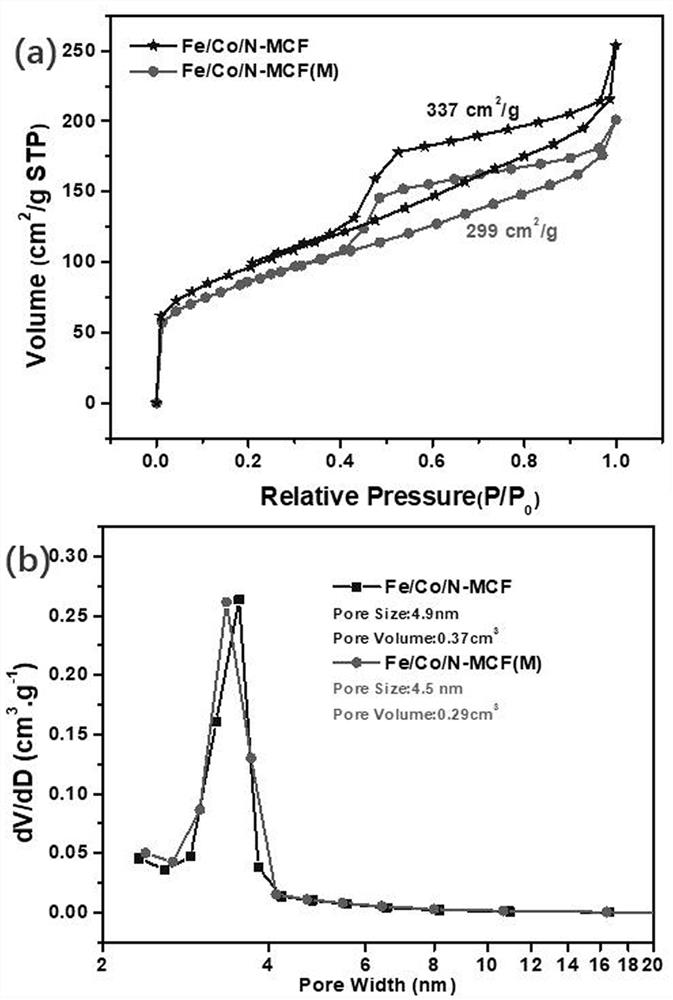

[0037] image 3 Be the specific surface area and the pore size distribution of the sample obtained in embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com