BP network model-based nuclear zirconium-4 alloy corrosion resistance prediction method, electronic equipment and storage medium

A BP network and performance prediction technology, applied in biological neural network models, weather/light/corrosion resistance, neural learning methods, etc. Achieve the effect of improving the prediction accuracy and generalization ability, and solving the long development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

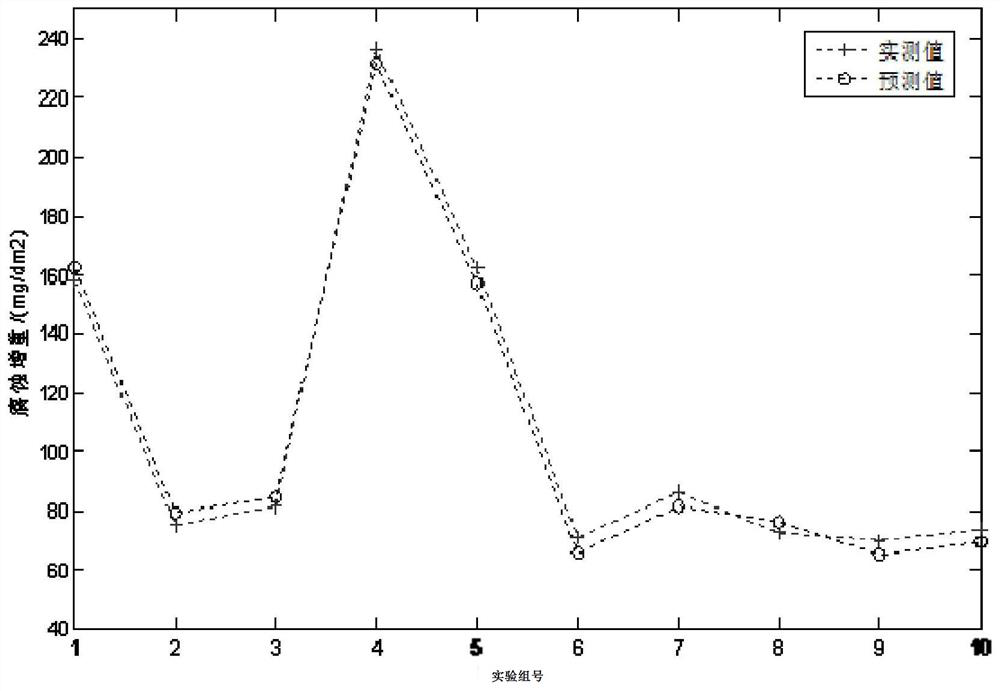

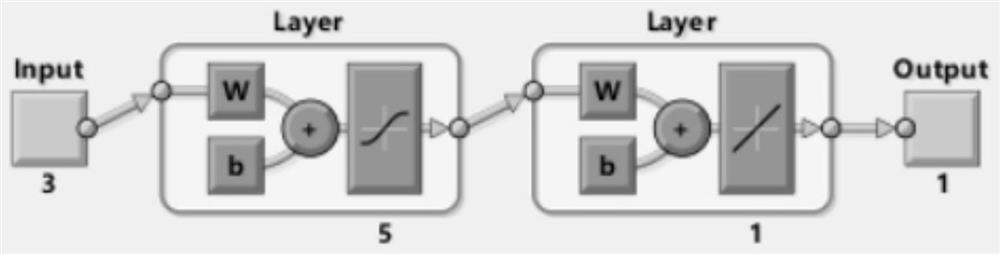

[0031] A method for predicting the corrosion resistance of zirconium-4 alloys for nuclear use based on the BP network model, such as figure 1 shown, including the following steps:

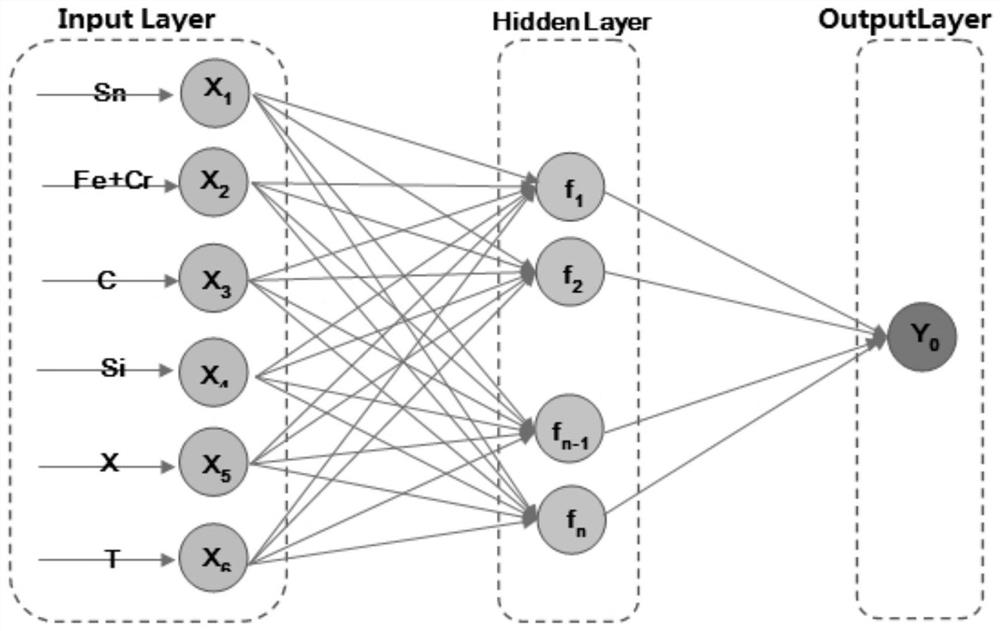

[0032]Obtain the original data samples, and use the corrosion weight gain data of nuclear zirconium-4 alloy plate samples with a size of 20mm×20mm×2mm at 400°C / 10.3MPa and 300 days under different alloy compositions as training samples, as shown in Table 1, input variable selection Sn content, Fe+Cr content, C content, Si content, X content and corrosion cycle T, the output variable is the corrosion weight gain of the plate sample (mg / dm 2 ).

[0033] Table 1 Types and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com