Improved axle housing assembly of steering drive axle for special vehicle

A steering drive axle, improved technology, applied in the directions of axles, wheels, vehicle parts, etc., can solve the problems of not being able to mass-produce axles, changing the mold of the axle housing body, and changing the state of the vehicle model frequently. Serialization, solve the long development cycle, solve the effect of high cost of developing molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

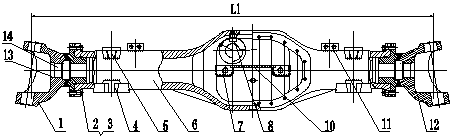

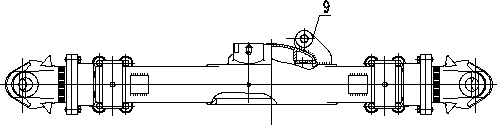

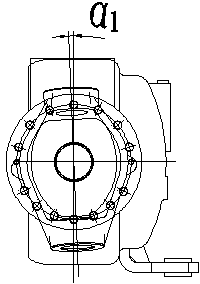

[0015] The accompanying drawing shows an embodiment structure of the improved steering drive axle assembly for special vehicles according to the present invention. The improved axle housing assembly consists of a left steering knuckle support seat assembly 1, a lower leaf spring seat 4, Leaf spring seat 5, axle housing body 6, positioning pin seat 7, oil baffle plate 8, booster cylinder bracket 9, oil guide groove 10, limit seat 11, right steering knuckle support seat assembly 12 are fixedly connected, and the axle housing The main body 6 and the left and right steering knuckle support seat assemblies 1, 12 are transitionally fitted through the inner and outer spigots and connected with the connecting bolt 2 and the spring washer 3, the lower leaf spring seat 4, the upper leaf spring seat 5, the positioning pin seat 7, and the oil retainer The plate 8, the booster cylinder support 9, the oil guide groove 10, the limit seat 11 and the axle housing body 6 are welded. After the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com