Manufacturing method of copper alloy seamless gas cylinder

The technology of a seamless gas cylinder and its manufacturing method is applied in the direction of container filling method, container discharge method, container structure manufacturing, etc., which can solve the problems of transmitter damage and unusability, and achieve high safety performance, high safety, The effect of high volume utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Manufacture a copper alloy seamless gas cylinder with a single port structure by the above method, in step 5) only one end of the gas cylinder is closed, the gas cylinder is as follows figure 1 As shown, the gas cylinder uses a copper alloy seamless container as the inner liner, and the inner liner is a spherical cylindrical structure, and its outer surface is fully wound with a carbon fiber composite material reinforcement layer impregnated with a resin matrix.

Embodiment 2

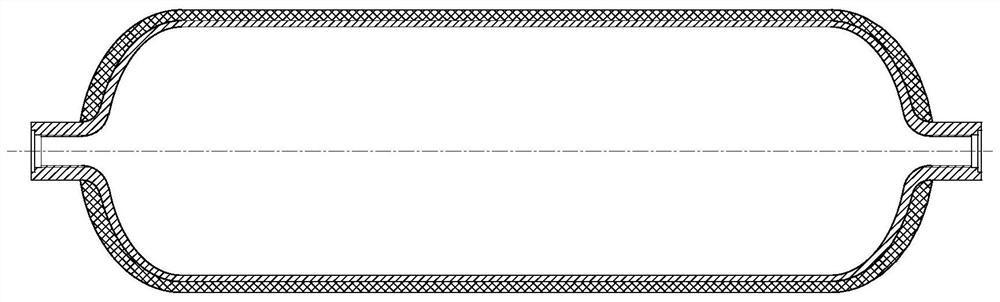

[0032] Embodiment 2: Manufacture a kind of copper alloy seamless gas cylinder of double-port structure by the above-mentioned method, in step 5) carry out closing processing to gas cylinder two ends, gas cylinder such as figure 2 As shown, the gas cylinder uses a copper alloy seamless container as the inner liner, and the inner liner is a spherical cylindrical structure, and its outer surface is fully wound with a carbon fiber composite material reinforcement layer impregnated with a resin matrix.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com