Electret filter base paper based on natural plant fibers as well as preparation method and application of base paper

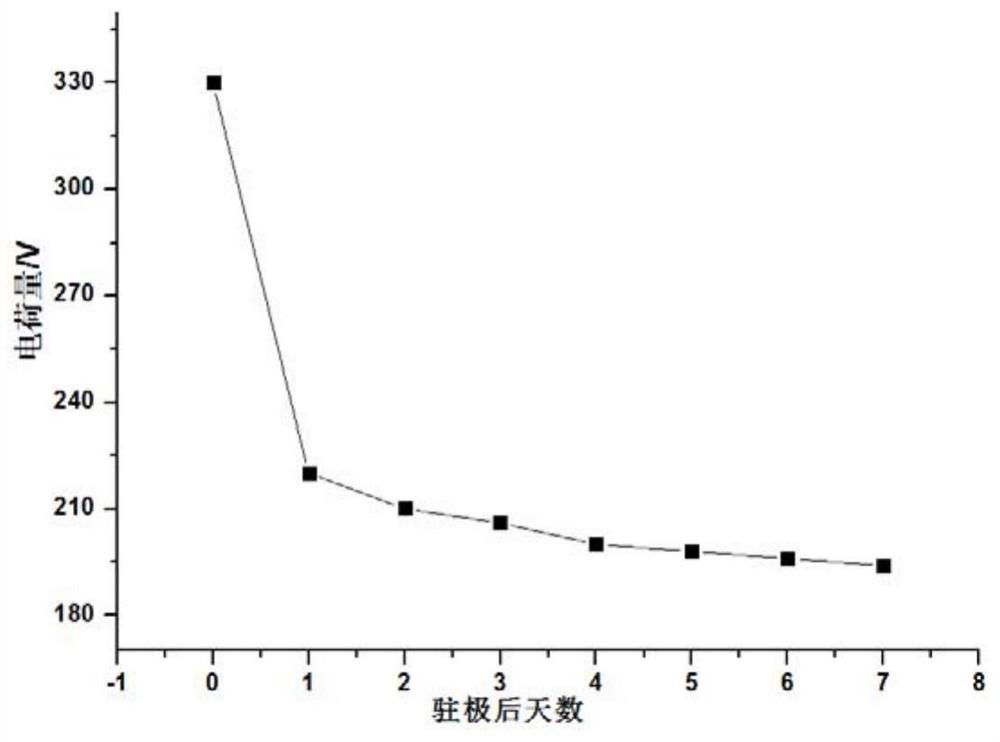

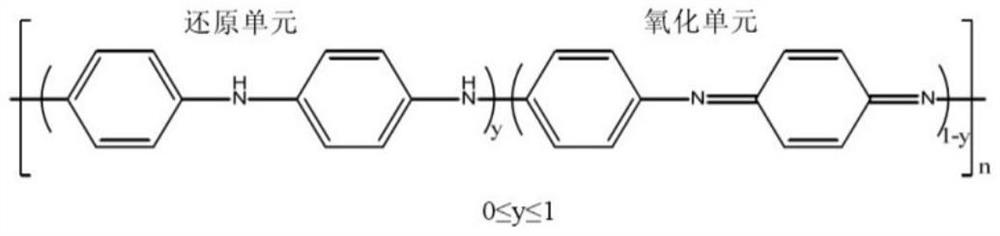

A natural plant fiber, electret technology, applied in natural cellulose pulp/paper, fiber raw material processing, cellulose pulp post-processing, etc., can solve the problem of not having electret, and achieve less and good functional electret. Mechanical properties, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

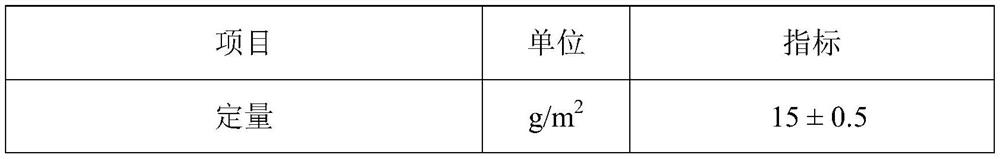

[0058] A kind of electret filter base paper based on natural plant fiber and preparation method thereof, comprises the following steps:

[0059] (1) Accurately weigh 10 g of absolute-dried bamboo pulp cellulose, loosen and disperse, and prepare the pulp to a concentration of 2%. Then add 0.1wt% aniline of the dry bamboo pulp cellulose pulp, adjust the pH to 1, and mix evenly under the condition of magnetic stirring to obtain the first suspension.

[0060] (2) Add the ammonium persulfate of 0.1wt% absolute dry bamboo pulp cellulose mass subsequently in the first suspension liquid, under ice-bath temperature 0 ℃, magnetic stirring reaction 1 hour, then filter, wash, dry in 105 ℃, The modified absolute dry bamboo pulp cellulose is obtained.

[0061] (3) Disperse and disperse the modified absolute-dried bamboo pulp cellulose evenly until the pulp concentration is 2%, to obtain the second suspension. Then in the second suspension, add dry bamboo pulp cellulose quality 1wt% polyla...

Embodiment 2

[0067] A kind of electret filter base paper based on natural plant fiber and preparation method thereof, comprises the following steps:

[0068] (1) Accurately weigh 10 g of dry hardwood pulp cellulose, loosen and disperse, and prepare the pulp to a concentration of 1%. Then add 0.2wt% pyrrole by weight of dry hardwood pulp cellulose, adjust the pH to 2, and mix evenly under the condition of magnetic stirring to obtain the first suspension.

[0069] (2) Subsequently, a potassium persulfate solution of 0.2 wt% of the absolute dry hardwood pulp cellulose mass was added to the first suspension, and the reaction was performed under magnetic stirring at ice bath temperature for 1.5 hours, then filtered, washed, and dried at 105° C. Obtain modified dry cellulose.

[0070] (3) Disperse and disperse the modified dry cellulose to a pulp concentration of 2%, to obtain a second suspension, add dry hardwood pulp cellulose quality 10wt% polylactic acid fiber, 2wt% polylactic acid fiber to...

Embodiment 3

[0076] A kind of electret filter base paper based on natural plant fiber and preparation method thereof, comprises the following steps:

[0077] (1) Accurately weigh 10 g of dry coniferous wood pulp cellulose, loosen and disperse, and prepare the pulp to a concentration of 5%. Then add 0.3wt% aniline by weight of dry softwood pulp cellulose, adjust the pH to 3, and mix evenly under the condition of magnetic stirring to obtain the first suspension.

[0078] (2) Then add 0.3wt% sodium persulfate solution to the first suspension, and react with magnetic stirring at ice bath temperature for 2 hours, then filter, wash, and dry at 105° C. to obtain modified absolute-dry cellulose.

[0079] (3) Disperse and disperse the modified dry cellulose to a slurry concentration of 2%, to obtain a second suspension, then add dry softwood pulp cellulose quality 8wt% polylactic acid fiber, 3wt% to the second suspension Polyvinyl alcohol (PVA), 1wt% SiO 2 , 0.5wt% nano-cellulose, and then disent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com