Bioreactor auxiliary device and operation method thereof

A bioreactor and auxiliary device technology, applied in bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical cleaning device, etc. Insufficient accuracy, time-consuming and labor-intensive problems, to achieve the effect of powerful functions, high degree of automation, and high data reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in further detail below in conjunction with the accompanying drawings.

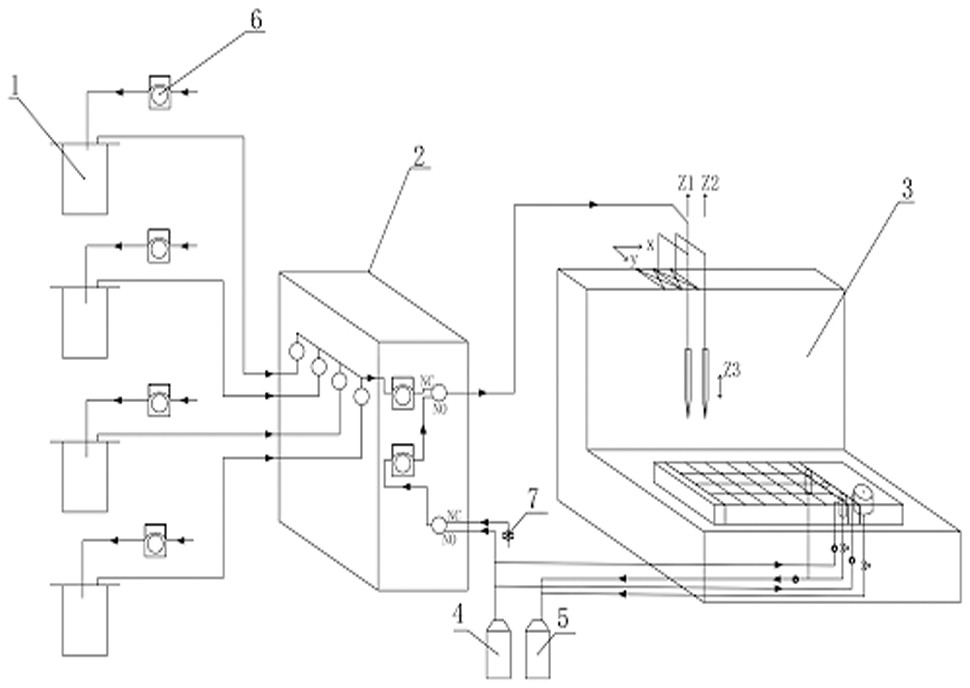

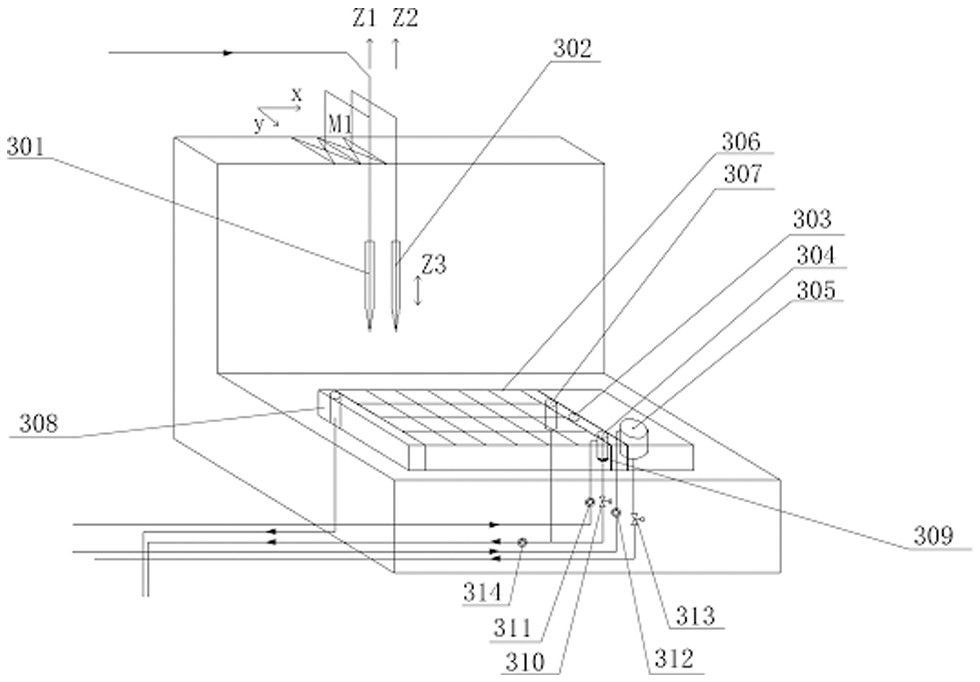

[0050] like figure 1 , figure 2 and image 3 As shown, a bioreactor auxiliary device includes a bioreactor 1, a sampler 2, a storage and analyzer 3, a buffer bottle 4, a waste liquid bottle 5 and a feedback feed pump 6; the bioreactor 1 is connected to Sampler 2, the sampler 2 is connected to the storage and analyzer 3, the buffer bottle 4 and the waste liquid bottle 5 are connected between the sampler 2 and the storage and analyzer 3, and the feedback feeding pump 6 passes through a silicone hose Connected to bioreactor 1, the switch and flow rate of the feedback feed pump can be adjusted according to the analysis result data.

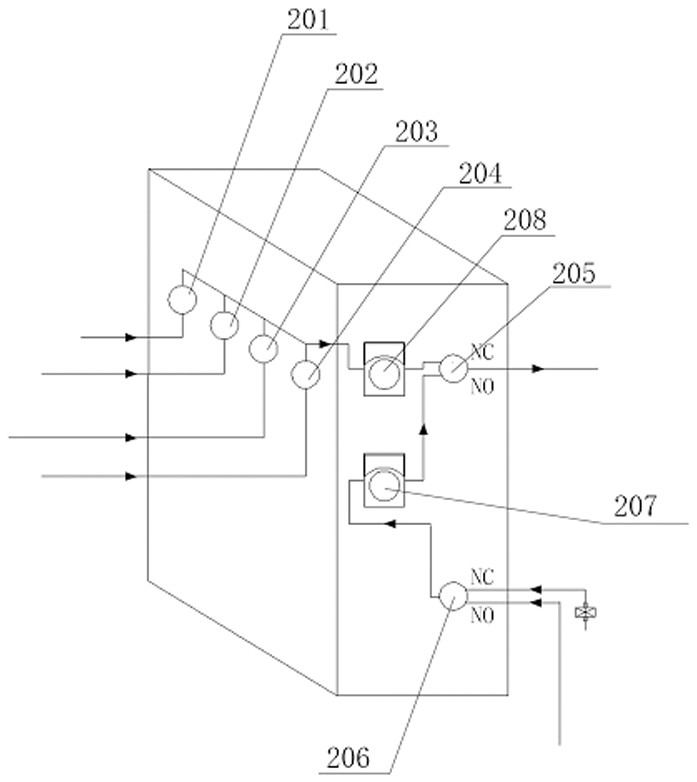

[0051] Further, the sampler 2 includes a box, and the 1# reactor sampling valve 201, the 2# reactor sampling valve 202, the 3# reactor sampling valve 203, the 4# reactor sampling valve 204, the main channel are installed in the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com