Textile sewage treatment device with filtering mechanism

The technology of a sewage treatment device and a filtering mechanism, which is applied in the textile field, can solve the problems of easy blockage of the filter screen of the drainage pipe and the inability to realize the removal of residues, and achieve the effect of reducing the probability of residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

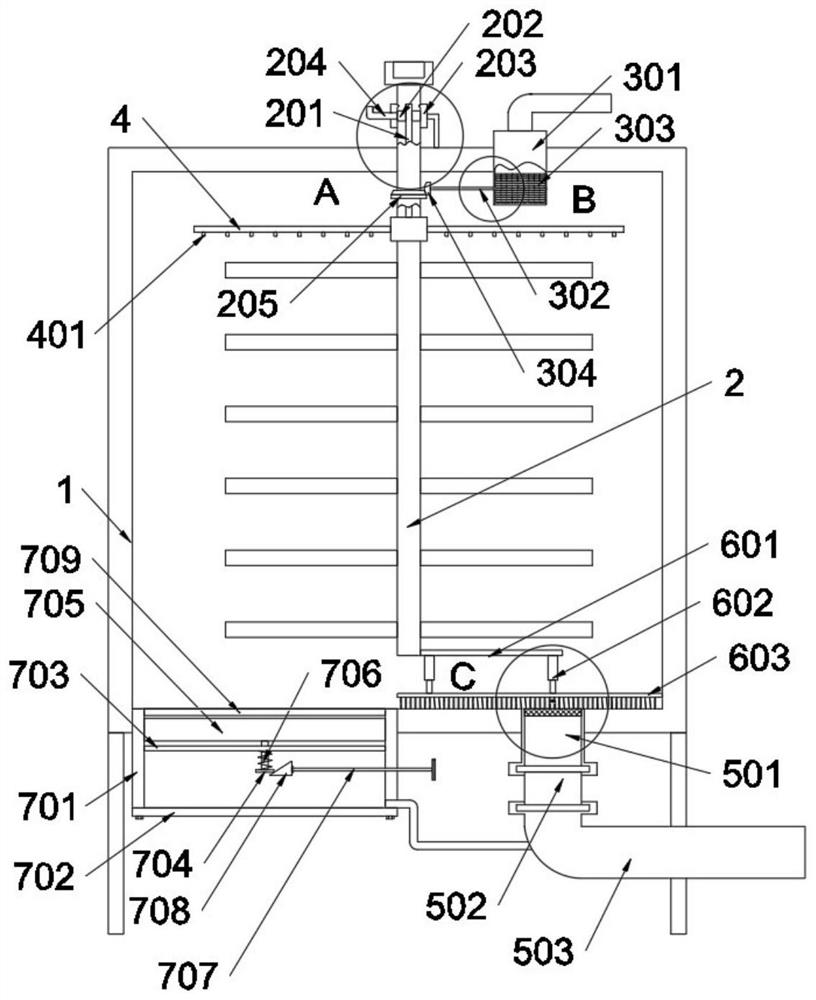

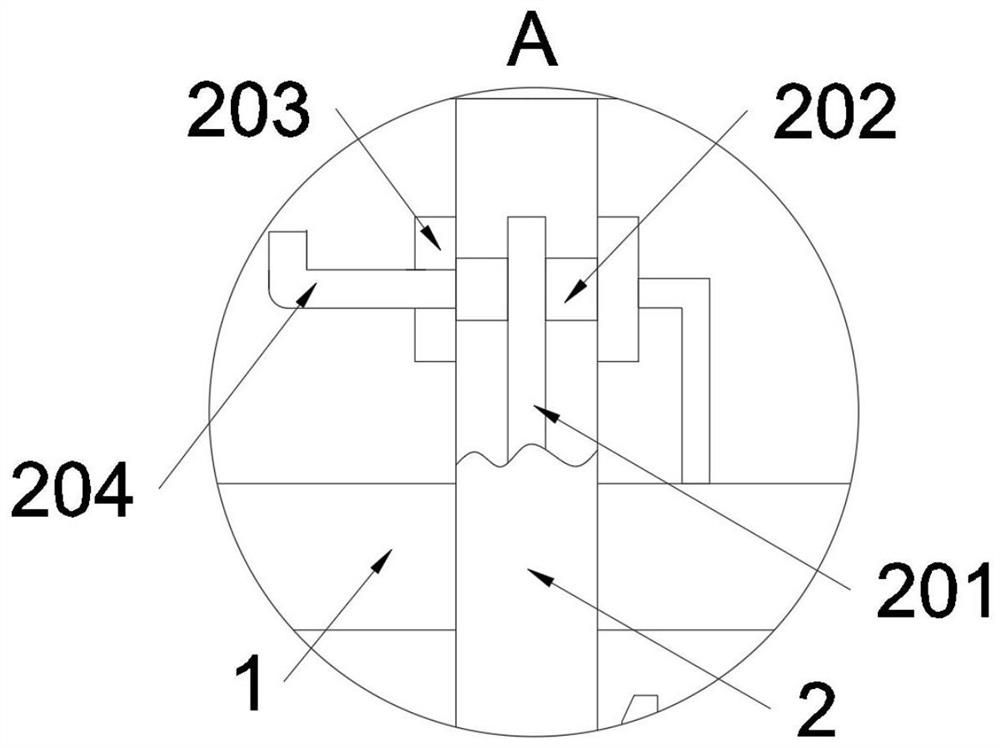

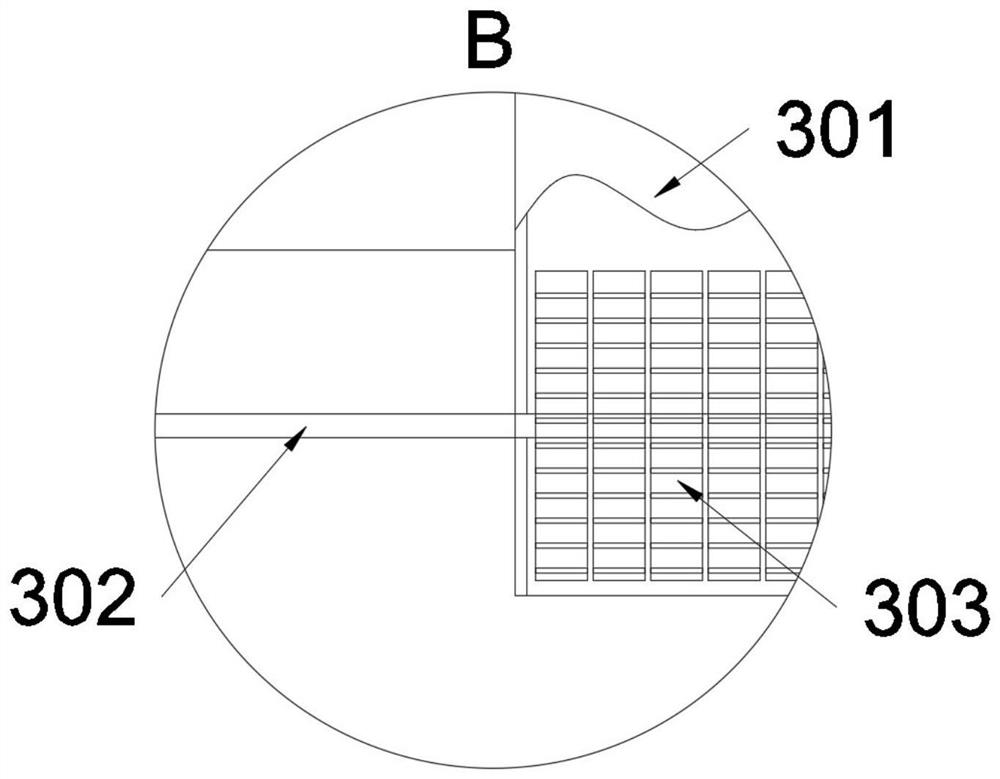

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The invention provides a textile sewage treatment device with a filtering mechanism, which includes a barrel body 1; Feed seat 4; bucket body 1 is equipped with drainage pipe structure 5, and bucket body 1 is also equipped with collection structure 7; stirring shaft 2 is equipped with cleaning structure 6; refer to as Figure 7 and Figure 8 , the collection structure 7 includes a threaded rod 707 and a drive block 708, the threaded rod 707 is threadedly connected to the collection box 701, and the head end of the threaded rod 707 is rotatably connected with a drive block 708; the left end surface of the drive block 708 is in contact with the tail end of the sliding shaft 704 , and the left end surface of the driving block 708 is an inclined structure, so that the screw threaded rod 707 can realize the sliding up and down adjustment of the sliding shaft 704 and the sealing block 705; refer to as Figure 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com