Composite aluminum-plastic film as well as preparation method and application thereof

A composite aluminum and plastic film technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve the problems of aluminum-plastic film without flame retardancy and poor safety, so as to improve safety, enhance flame retardancy, The effect of high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

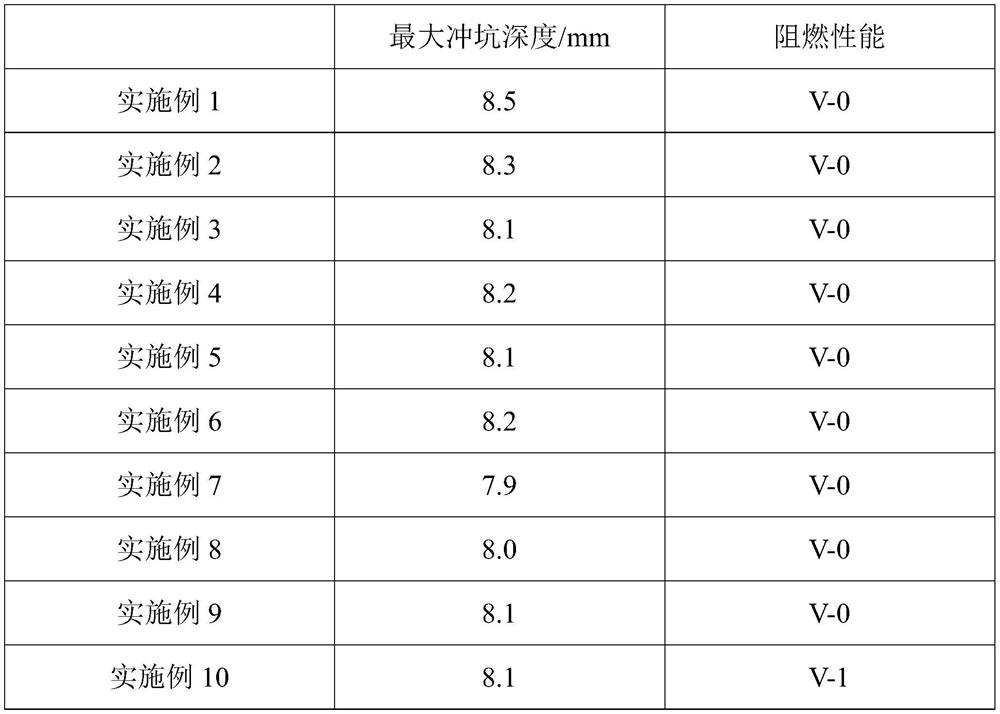

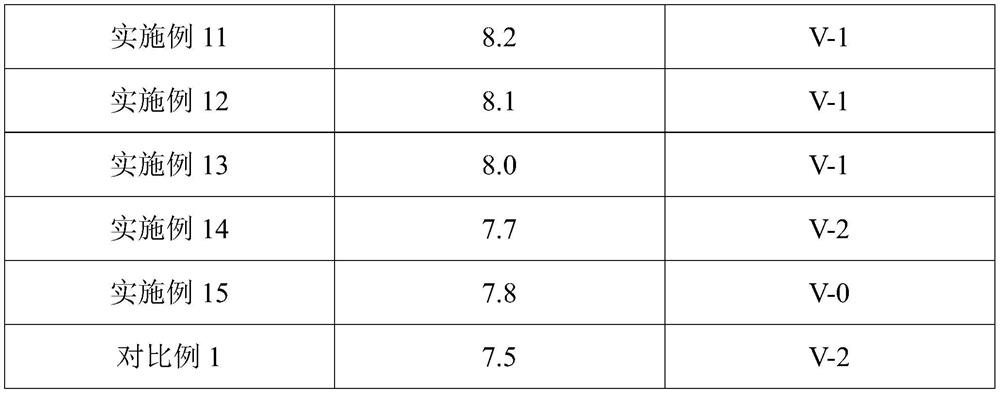

Examples

Embodiment 1

[0041] This embodiment provides a method for preparing a composite aluminum-plastic film, the preparation method comprising:

[0042] (1) Nylon fibers are immersed in the flame retardant tetrakis hydroxymethyl phosphorus chloride, the mass concentration of the flame retardant is 25wt%, and the immersion time is 24h to obtain the nylon fibers after the flame retardant treatment;

[0043] (2) Nylon fibers treated with a flame retardant at a mass ratio of 1:1 are blended with poly-p-phenylenebenzobisoxazole fibers to obtain a protective layer with a thickness of 2.5 μm;

[0044](3) Laminating the protective layer obtained in step (2) with an aluminum layer with a thickness of 40 μm and a polypropylene layer with a thickness of 35 μm to obtain a composite aluminum-plastic film.

Embodiment 2

[0046] This embodiment provides a method for preparing a composite aluminum-plastic film, the preparation method comprising:

[0047] (1) Nylon fibers are immersed in the flame retardant tetrakis hydroxymethyl phosphorus chloride, the mass concentration of the flame retardant is 28wt%, and the immersion time is 22h to obtain the nylon fibers after the flame retardant treatment;

[0048] (2) Nylon fibers treated with a flame retardant with a mass ratio of 2:3 are blended with poly-p-phenylene benzobisoxazole fibers to obtain a protective layer with a thickness of 2.7 μm;

[0049] (3) Laminating the protective layer obtained in step (2) with an aluminum layer with a thickness of 38 μm and a polypropylene layer with a thickness of 38 μm to obtain a composite aluminum-plastic film.

Embodiment 3

[0051] This embodiment provides a method for preparing a composite aluminum-plastic film, the preparation method comprising:

[0052] (1) Nylon fibers are immersed in the flame retardant tetrakis hydroxymethyl phosphorus chloride, the mass concentration of the flame retardant is 22wt%, and the immersion time is 26h to obtain the nylon fibers after the flame retardant treatment;

[0053] (2) Nylon fibers treated with a flame retardant at a mass ratio of 1:2 are blended with poly-p-phenylene benzobisoxazole fibers to obtain a protective layer with a thickness of 2.2 μm;

[0054] (3) Laminating the protective layer obtained in step (2) with an aluminum layer with a thickness of 42 μm and a polypropylene layer with a thickness of 32 μm to obtain a composite aluminum-plastic film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com