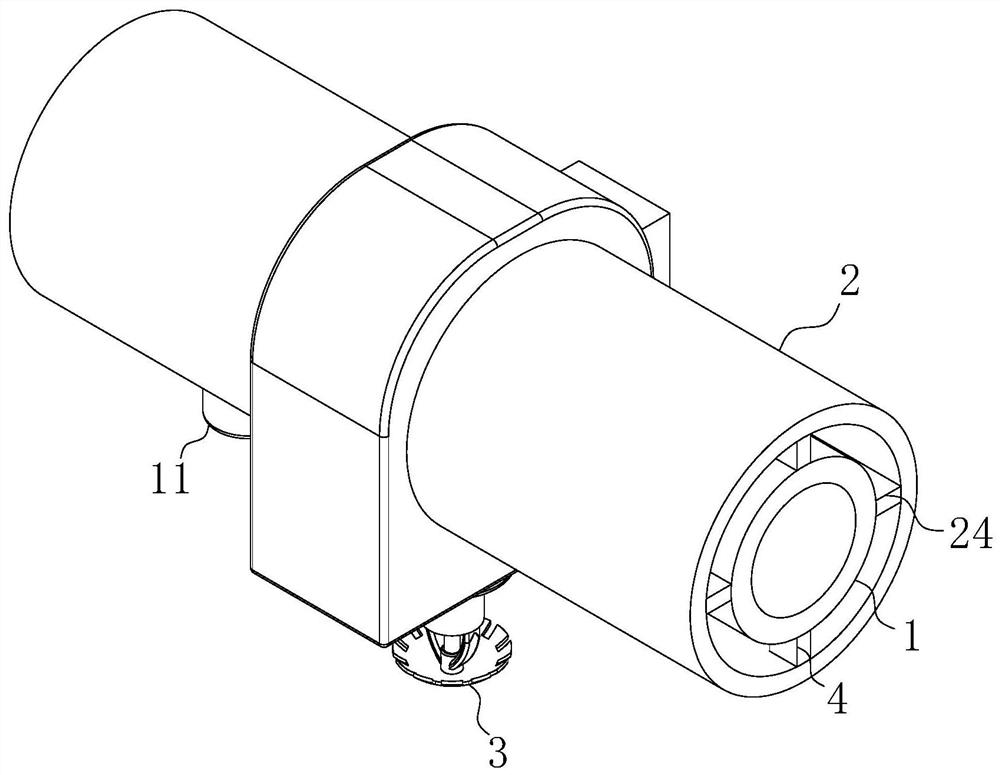

Anti-blocking rapid spraying equipment

A spray equipment and anti-clogging technology, applied in the direction of spray devices, etc., can solve the problems of glass tube burst, increase the cost of providing heat energy, damage to spray equipment, etc., so as to reduce the risk of freezing, improve the cleaning effect, and meet the fire protection requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

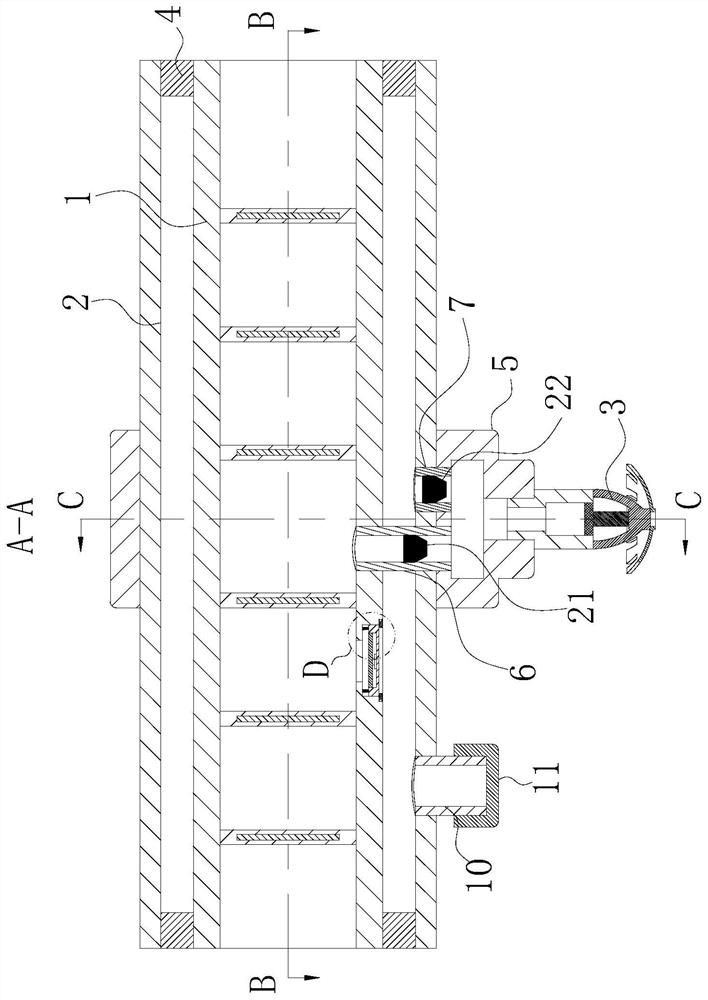

[0029] As an embodiment of the present invention, the inner conduit 1 is provided with limiting grooves near the opening below the adjustment hole; the number of the limiting grooves is two, and they are arranged symmetrically; the insides of the two limiting grooves are both The limit block 14 is slidingly connected, and the bottom of the limit groove is fixedly connected with the second electric telescopic rod 15, and the second electric telescopic rod 15 is fixedly connected with the corresponding limit block 14 respectively; during work, when When the inside of the inner conduit 1 is pressurized and desilted, in order to avoid pressurization, the water inside the inner conduit 1 presses the regulating block 8, so that the inner conduit 1 and the outer conduit 2 are directly connected, resulting in resistance inside the inner conduit 1. The stagnant matter enters the inside of the outer conduit 2, which affects the normal operation of the outer conduit 2. By setting the limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com