Critical temperature testing system of gunpowder and explosive thermal explosion

A technology of critical temperature and test system, applied in the direction of material thermal development, etc., can solve problems such as personal safety threats, difficult data collection, failure to meet temperature field uniformity and stability requirements, etc., to improve temperature field uniformity and stability , the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

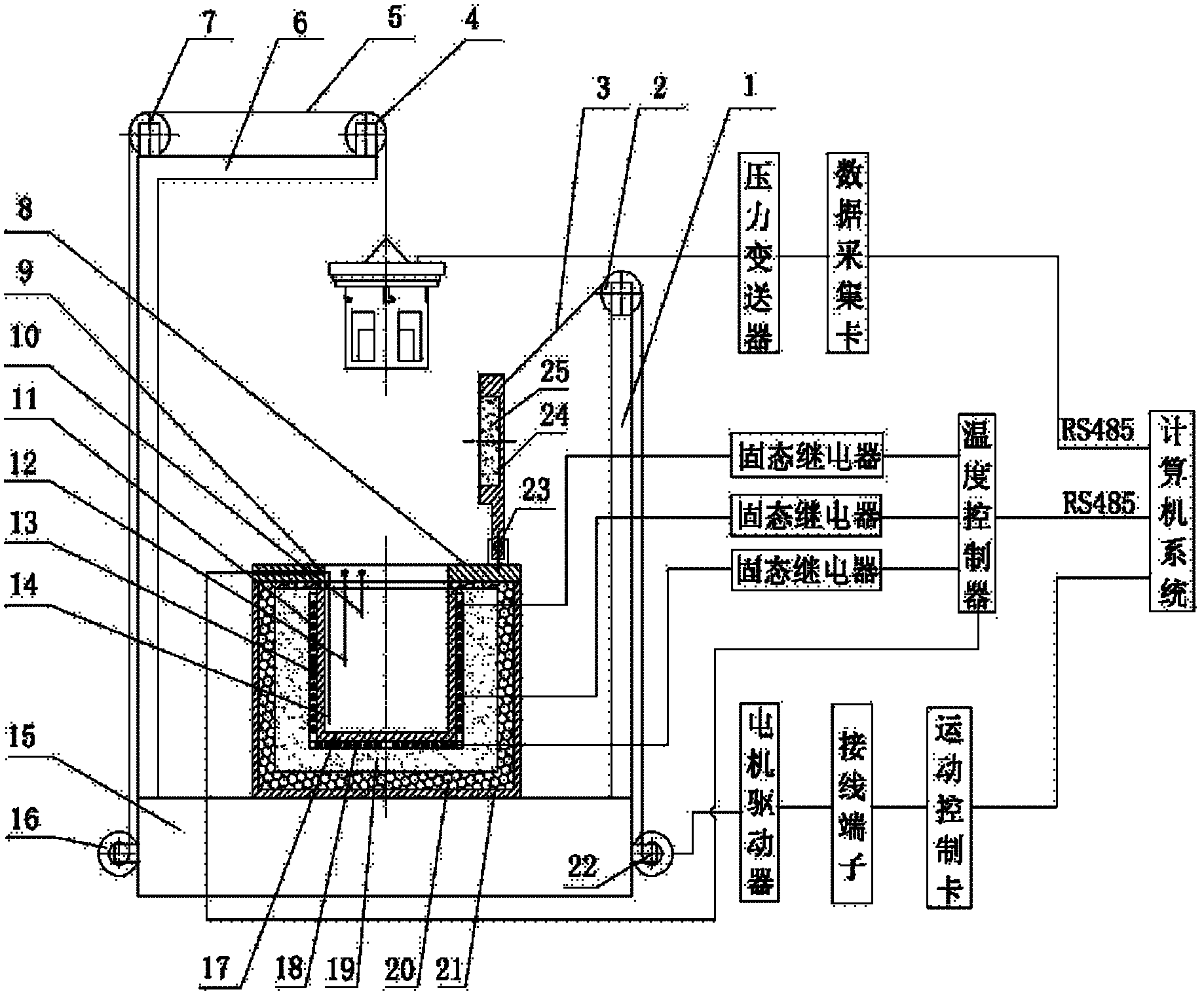

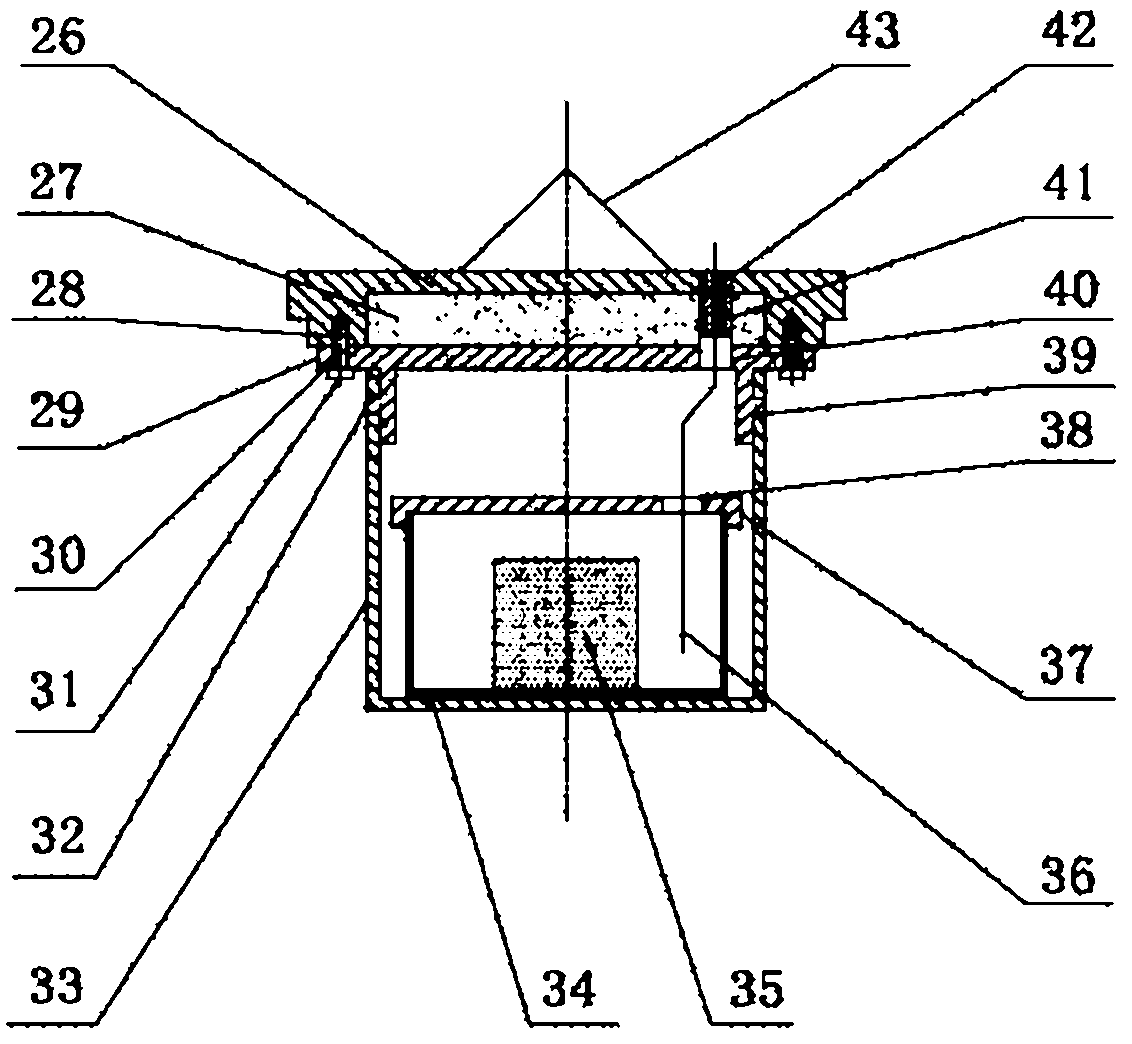

[0027] see Figure 1 ~ Figure 4 , the propellant thermal explosion critical temperature test system of the present invention includes a heating unit for heating, a reactor unit, an automatic sampling unit, a pressure detection unit and a computer.

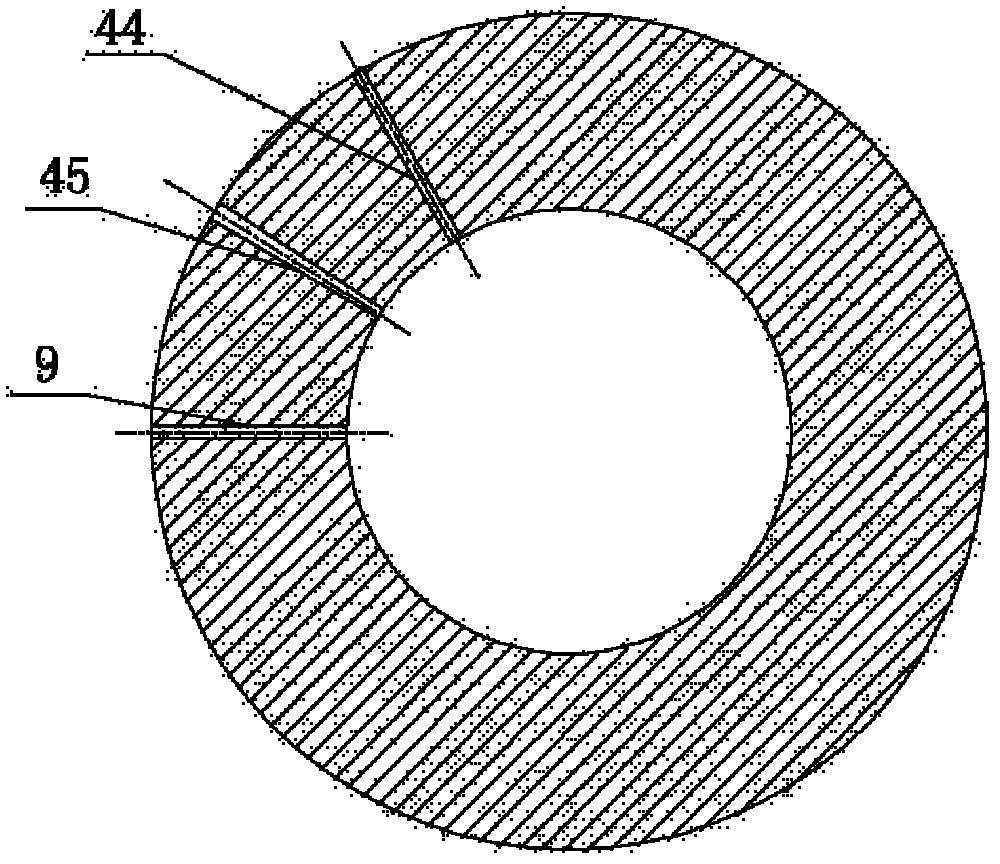

[0028] The heating unit for heating comprises a single-cavity heating furnace body with a thermal conduction layer 17, three groups of heating layers (upper heating layer 11, middle heating layer 13, lower heating layer 18), asbestos insulation layer 19, and ceramic insulation layer 20. There are independent heating wires in the heating layer; the bottom, middle and upper parts of the furnace cavity are respectively equipped with an upper layer temperature sensor 10 connected to the computer, a middle layer temperature sensor 12, and a lower layer temperature sensor 14. There are solid state relays and temperature controllers outside the heating furnace body , the outermost layer of the heating furnace body is a shell 21, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com