Sulfanilamide micromolecule surface modified polyamide composite membrane and preparation method thereof

A surface modification, small molecule technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problem of inability to fully meet the use of large areas, the decline of water flux and salt rejection, and the inability to obtain ideal aquatic products. To improve the anti-fouling ability, reduce the surface roughness of the membrane, and improve the water flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

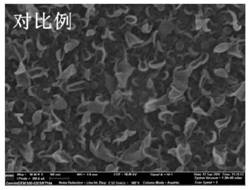

Examples

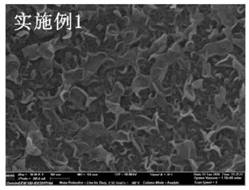

Embodiment 1

[0044] A sulfonamide small molecule modified surface polyamide composite membrane, the polyamide composite membrane includes an ultrafiltration bottom membrane and a polyamide layer modified by small molecules, and the polyamide layer covers the surface of the ultrafiltration bottom membrane;

[0045] The small molecule is p-aminobenzenesulfonamide.

[0046] The preparation method of described sulfonamide small molecule modified surface polyamide composite membrane comprises the following steps:

[0047] (1) Immerse the polysulfone ultrafiltration membrane in the mixed aqueous solution containing 2.4wt% camphorsulfonic acid, 1.1wt% triethylamine and 2.0wt% m-phenylenediamine for 2min, then take out and remove the water on the surface phase solution;

[0048] (2) Immerse the polysulfone ultrafiltration membrane treated in the step (1) in the n-hexane solution containing 0.1wt% trimesoyl chloride for 1min, then take out and remove the organic phase solution on the surface, rins...

Embodiment 2

[0051] A sulfonamide small molecule modified surface polyamide composite membrane, the polyamide composite membrane includes an ultrafiltration bottom membrane and a polyamide layer modified by small molecules, and the polyamide layer covers the surface of the ultrafiltration bottom membrane;

[0052] The small molecule is p-aminobenzenesulfonamide.

[0053] The preparation method of described sulfonamide small molecule modified surface polyamide composite membrane comprises the following steps:

[0054] (1) Immerse the polysulfone ultrafiltration membrane in the mixed aqueous solution containing 2.4wt% camphorsulfonic acid, 1.1wt% triethylamine and 2.0wt% m-phenylenediamine for 2min, then take out and remove the water on the surface phase solution;

[0055] (2) Immerse the polysulfone ultrafiltration membrane treated in the step (1) in the n-hexane solution containing 0.1wt% trimesoyl chloride for 1min, then take out and remove the organic phase solution on the surface, rins...

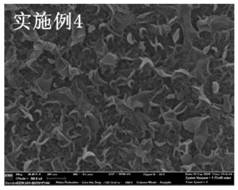

Embodiment 3

[0058] A sulfonamide small molecule modified surface polyamide composite membrane, the polyamide composite membrane includes an ultrafiltration bottom membrane and a polyamide layer modified by small molecules, and the polyamide layer covers the surface of the ultrafiltration bottom membrane;

[0059] The small molecule is m-aminobenzenesulfonamide.

[0060] The preparation method of described sulfonamide small molecule modified surface polyamide composite membrane comprises the following steps:

[0061] (1) Immerse the polysulfone ultrafiltration membrane in the mixed aqueous solution containing 2.4wt% camphorsulfonic acid, 1.1wt% triethylamine and 2.0wt% m-phenylenediamine for 2min, then take out and remove the water on the surface phase solution;

[0062] (2) Immerse the polysulfone ultrafiltration membrane treated in the step (1) in the n-hexane solution containing 0.1wt% trimesoyl chloride for 1min, then take out and remove the organic phase solution on the surface, rins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com