Evaluation method for moisturizing properties of cigarettes

A technology of moisturizing performance and evaluation method, applied in the field of tobacco, can solve the problems of cumbersome evaluation method, influence of environmental factors, long detection period, etc., and achieves the effects of short detection period, reduced material loss, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Sansi pretreatment: place the three cigarettes respectively in a constant temperature and humidity chamber at a temperature of (22±1)°C and a relative humidity of (60±2)% for 48 hours to be used for standby;

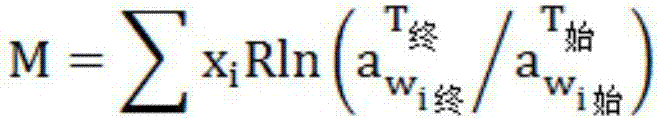

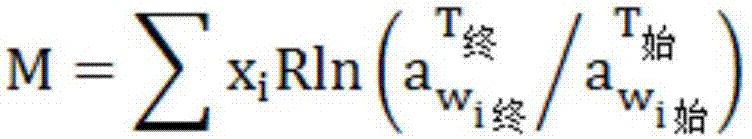

[0021] (2) The three wires are measured separately: each sample is taken out of the constant temperature and humidity chamber after being balanced for 48 hours, sealed and placed in the test environment to balance for a period of time, and then the initial water activity of each sample is detected with a water activity meter wi始 and initial temperature T 始 , and the termination water activity a after a predetermined period of time wi终 and termination temperature T 终 . Before starting the measurement, ensure that the sample is in a sealed state, and place it in the same environment as the sensor for 30 minutes to achieve complete equilibrium, so as to avoid humidity transfer between the sample and the environment before and after the test. Put the substance ...

Embodiment 2

[0029] (1) Sansi pretreatment: place the three cigarettes respectively in a constant temperature and humidity chamber at a temperature of (22±1)°C and a relative humidity of (60±2)% for 48 hours to be used for standby;

[0030] (2) The three wires are measured separately: each sample is taken out of the constant temperature and humidity chamber after being balanced for 48 hours, sealed and placed in the test environment to balance for a period of time, and then the initial water activity of each sample is detected with a water activity meter wi始 and initial temperature T 始 , and the termination water activity a after a predetermined period of time wi终 and termination temperature T 终 . Before starting the measurement, ensure that the sample is in a sealed state, and place it in the same environment as the sensor for 30 minutes to achieve complete equilibrium, so as to avoid humidity transfer between the sample and the environment before and after the test. Put the substance ...

Embodiment 3

[0038] (1) Pre-treatment of shredded tobacco: put the shredded tobacco in a constant temperature and humidity chamber with a temperature of (22±1)°C and a relative humidity of (60±2)% to balance for 48 hours for later use;

[0039] (2) Spray humectant: take out the shredded tobacco after equilibrating for 48h, weigh four portions, 10g each, and spray the control (deionized water), propylene glycol, and self-developed humectant at a ratio of 0.5% with a throat sprayer 1#, after mixing evenly, open it and place it in a constant temperature and humidity box for testing.

[0040] (3) Each sample is sealed and placed in the test environment to balance for a period of time, and then the initial water activity of each sample is detected with a water activity meter a wi始 and initial temperature T 始 , and the termination water activity a after a predetermined period of time wi终 And the termination temperature T end. Before starting the measurement, ensure that the sample is in a sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com