Preparation method of nanoparticle-containing modified cellulose ultrafiltration membrane

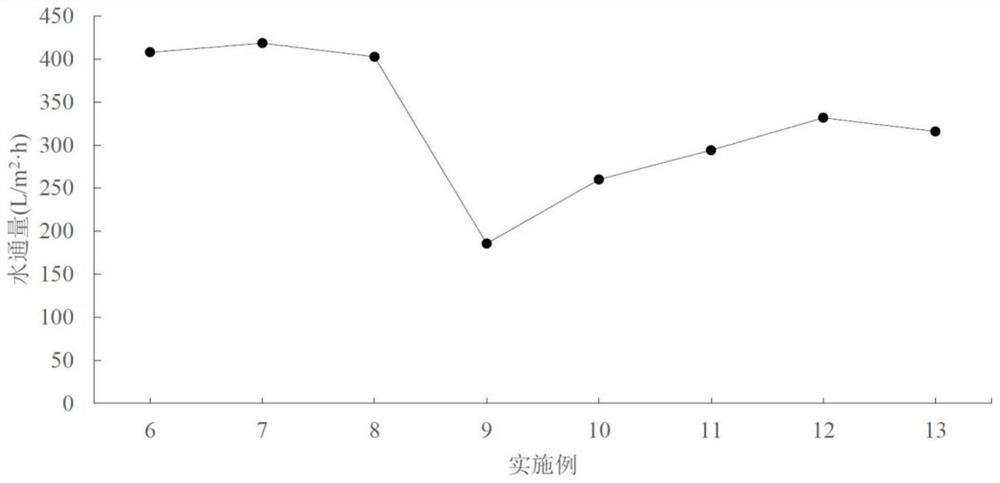

A nanoparticle modification, nanocellulose technology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems of poor anti-pollution, poor acid and alkali resistance, and reduced service life of ultrafiltration membranes, and achieve excellent Oxide resistance, good mechanical properties, high water flux effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Embodiment 1: a kind of silica nanoparticle:

[0069] 1) Dissolve 2g of cetyltrimethylammonium bromide in 8g of 1.0mol / L sodium hydroxide solution to make a weakly alkaline solution, slowly drop in 15g of tetraethyl orthosilicate at a rate of 5mL / min, 50 Stir at a high speed of 4500r / min for 4 hours at ℃ until a precipitate is formed, and the precipitate is washed with methanol and deionized water in turn until the washing liquid is neutral;

[0070] 2) Step 1) Dry the precipitate in a vacuum oven at 60°C to constant weight, add 3-aminopropyl-triethoxysilane 5 times the weight of the precipitate and 150g of absolute ethanol, reflux in a -80°C refrigerator for 12 hours, and anhydrous After washing with ethanol for 3 times, dry in a vacuum oven at 50°C for 4 hours to obtain aminated silica nanoparticles;

[0071] 3) Dissolve 1 g of hyaluronic acid (molecular weight 1000 KDa) in a large amount of deionized water, adjust the pH to 4.8, add 50 mg of EDC and 80 mg of NHS, st...

Embodiment 2

[0072] Example 2: Another silica nanoparticle:

[0073] Dissolve 2g of cetyltrimethylammonium bromide in 8g of 1.0mol / L sodium hydroxide solution to make a weakly alkaline solution, slowly drop in 15g of tetraethyl orthosilicate at a rate of 5mL / min, at 50°C Stir at a high speed of 4500r / min for 4h until precipitation occurs, wash the precipitate with methanol and deionized water in turn until the washing solution is neutral, and dry in a vacuum oven at 60°C until constant weight.

Embodiment 3

[0074] Example 3: Another silica nanoparticle:

[0075] 1) Dissolve 2g of cetyltrimethylammonium bromide in 8g of 1.0mol / L sodium hydroxide solution to make a weakly alkaline solution, slowly drop in 15g of tetraethyl orthosilicate at a rate of 5mL / min, 50 Stir at a high speed of 4500r / min for 4 hours at ℃ until a precipitate is formed, and the precipitate is washed with methanol and deionized water in turn until the washing liquid is neutral;

[0076] 2) Step 1) Dry the precipitate in a vacuum oven at 60°C to constant weight, add 3-aminopropyl-triethoxysilane 5 times the weight of the precipitate and 150g of absolute ethanol, reflux in a -80°C refrigerator for 12 hours, and anhydrous After washing with ethanol for 3 times, dry in a vacuum oven at 50° C. for 4 hours to obtain aminated silica nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com