Liner structure of bulletproof helmet and manufacturing process thereof

A bulletproof helmet and manufacturing process technology, which is applied to helmets, helmet caps, headgear products, etc., can solve the problems of affecting the normal performance of the wearer's tactical movements, reducing the air flow of the bulletproof helmet, affecting the wearer's comfort, etc., so as to preserve the human body. Moisture, easy to take and wear, reduce sweating frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

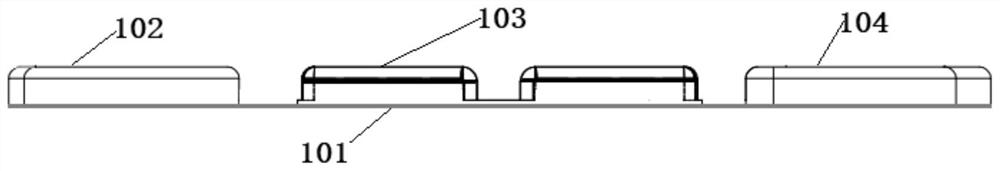

[0064] As an example, according to the requirements of the impact resistance level, the buffer layer 101 can be increased to a certain thickness, while reducing the thickness of the comfort layer, and the impact resistance can be greatly improved under the condition that the weight of the pad structure remains unchanged.

Embodiment 2

[0066] As an example, the waterproof film layer of the comfort layer and buffer layer 101 adopts a film structure formed after the waterproof coating is heated, which greatly enhances the ability of the comfort layer and buffer layer 101 to resist sweat or steam erosion;

Embodiment 3

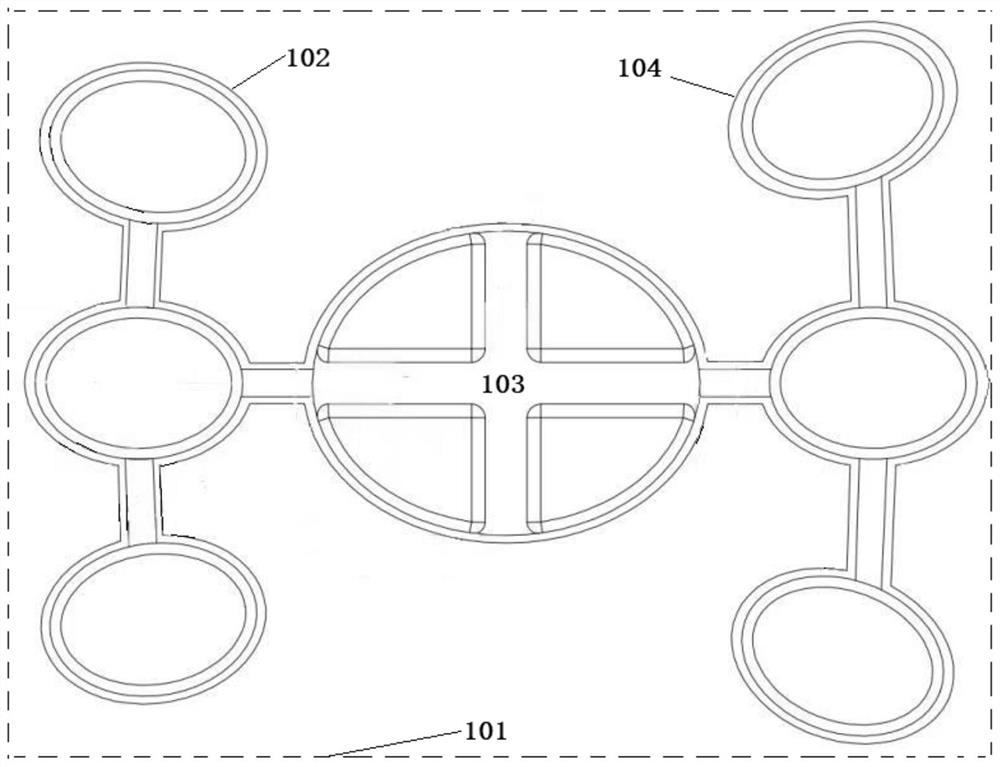

[0068] As a preferred example, the central cross groove structure of the top structure 103 has a cross groove width of 1.5 cm and a groove depth of 1.0 cm. This parameter is obtained from multiple experiments and can disperse the force on the top of the head. Relieve the feeling of oppression, and at the same time, evacuate the hot steam on the top of the head, lower the temperature, and adjust the optimal experimental parameters for comfort.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com