Method for preventing electric connector of manufacturing process from falling off

A technology for electrical connectors and manufacturing processes, which is applied to parts of connecting devices, devices for connecting/disconnecting connecting parts, connections, etc., can solve the problem that electrical connections are easily pulled or dragged, electrical connectors cannot work normally, It is difficult to deal with problems such as pulling and dragging, so as to achieve the effect of increasing the contact guide effect, simple structure and convenient insertion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

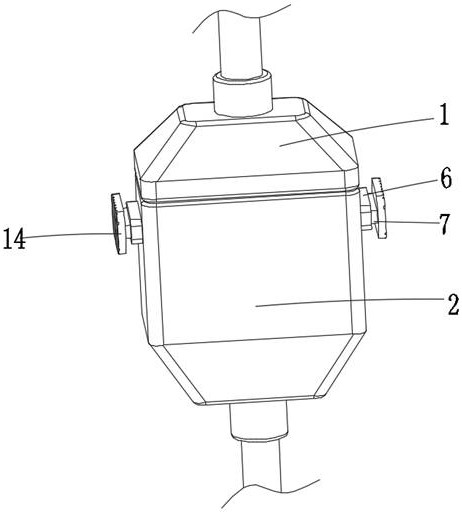

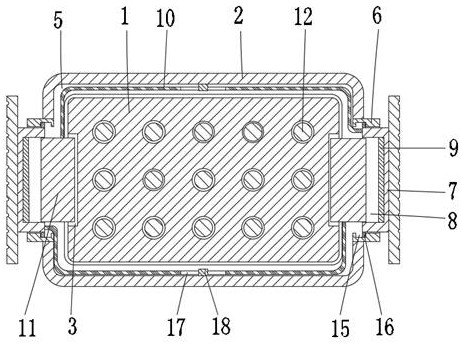

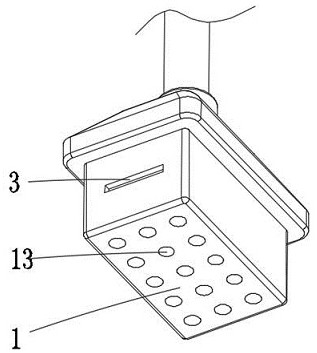

[0034] The magnetic suction type electric connector of a kind of manufacturing process technology of this embodiment, refer to Figure 1-4 : Including the male plug 1 and the female plug 2, the left and right sides of the male plug 1 are provided with a magnetically conductive metal groove 3, the upper side of the female plug 2 is provided with a slot 4, the inner wall of the middle part of the slot 4 is provided with an annular groove 5, and the female plug 2 The upper part is provided with protrusions 6 on the left and right sides, and the middle part of the protrusions 6 is provided with a sliding port which communicates with the annular groove 5, and a guide slider 7 is slidably connected in the sliding port, and the guide slider 7 is provided with a concave groove on the side close to the slot 4. Groove 8, the inner wall of the groove 8 away from the slot 4 side is provided with a first magnetic block 9, and the side of the guide slider 7 close to the slot 4 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com