Tunnel pavement longitudinal crack reinforcing treatment construction method

A technology of longitudinal cracks and construction methods, applied in the directions of roads, roads, road construction reinforcements, etc., can solve problems such as tunnel pavement cracking, and achieve the effect of preventing further expansion and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

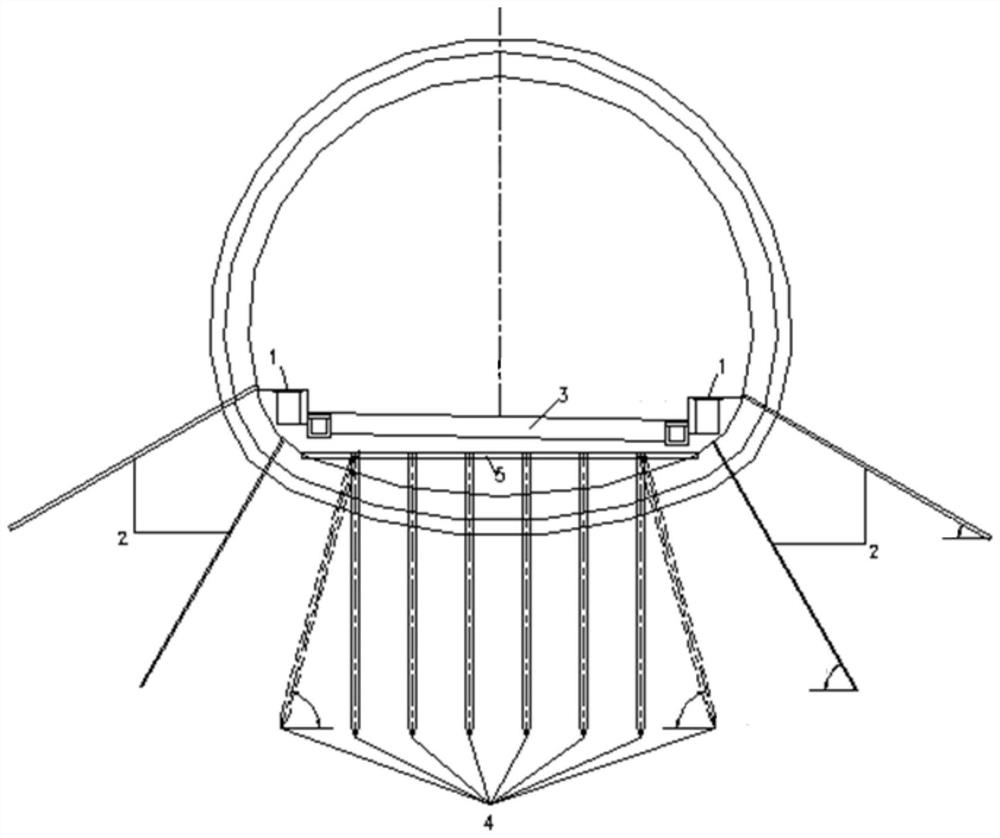

[0021] combine figure 1 The cross-sectional view of the tunnel treatment shows the cable trough 1, the lock foot anchor pipe 2, the road surface 3, the micro steel pipe pile 4, and the I-beam 5. The I-beam 5 is connected to the formed steel frame through the channel steel 6, the I-beam 7 and the expansion bolt 8 and anchored to the second lining structure.

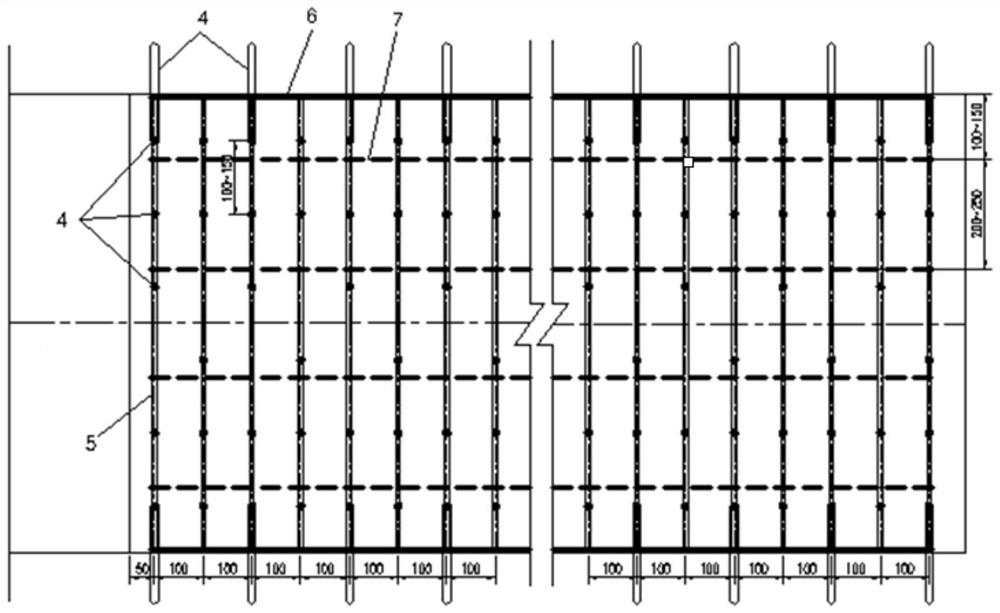

[0022] combine figure 2 The plan layout of the tunnel grouting pipe and steel arch frame shows the miniature steel pipe pile 4, the I-beam 5, the channel steel 6, and the I-beam 7, and the micro-steel pipe pile 4 is connected to the I-beam 5 by welding.

[0023] combine image 3 Schematic diagram of the joint between the channel steel and the transverse I-steel. It can be seen that the I-steel 5, the channel steel 6, and the expansion bolt 8 are connected by welding the I-steel 5 to the channel steel 6.

[0024] combine Figure 4 Schematic diagram of the junction of horizontal and vertical I-beams, I-beam 5 and I-beam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com