Method for endowing low-voltage arrester with automatic separation function

An automatic detachment and lightning arrester technology, applied in the field of lightning arresters, can solve the problems of inability to penetrate the air gap, low operating voltage of the lightning arrester, heat transfer to the disconnector, etc., so as to avoid electrified "arcing", prevent further expansion, and accelerate rapid disconnection open effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

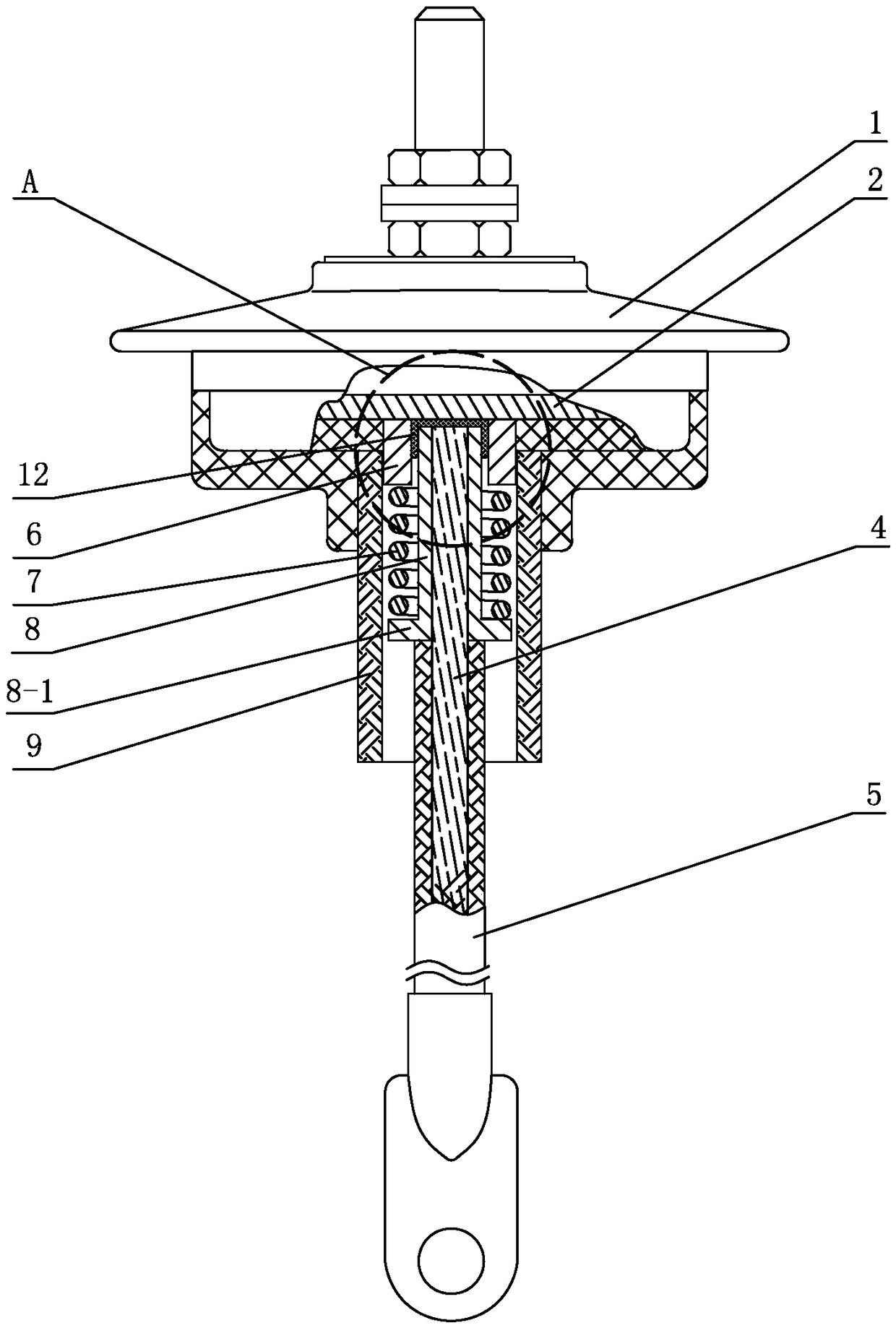

[0046] The present invention will be further described below in conjunction with the accompanying drawings.

[0047] In order to facilitate the understanding of this technical solution, several confusing technical issues are explained as follows:

[0048] 1. Low-voltage arresters are mainly used to prevent insulation damage caused by lightning. Therefore, for low-voltage arresters in the national standard, there are no residual voltage indicators for operation and steep wave impulse current.

[0049] 2. Due to the excellent non-linearity of the zinc oxide resistor, it can quickly discharge the current and reduce the lightning voltage amplitude under the nominal lightning impulse current, so there will be no power frequency short-circuit current.

[0050] 3. For low-voltage arresters, the short-circuit current is caused by the deterioration of the resistor sheet (also known as the valve sheet), which causes the leakage current to increase, causing the resistor sheet to heat up,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com