Preparation method of easily degradable differentiated excipients and excipients

A chemical auxiliary material and easy-to-degrade technology, applied in the textile field, can solve the problems of loose filaments, natural fibers without thermoplasticity, and loose edges after washing, so as to achieve the effects of enhancing strength, shortening the production process, and avoiding loss of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] A preparation method of easily degradable differentiated auxiliary materials, comprising the following steps:

[0037] (1) Pretreatment: bleaching long-staple cotton yarn and long-staple cotton fiber to obtain bleached cotton yarn and bleached cotton fiber. The long-staple cotton fibers may be long-staple cotton.

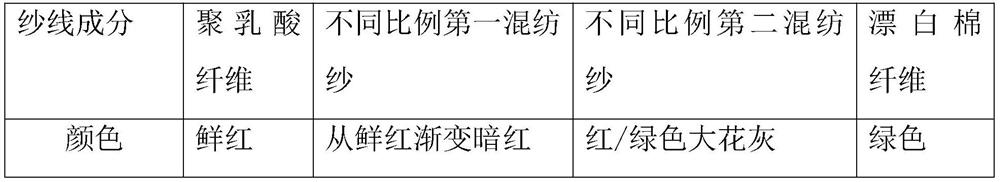

[0038] (2) The first blended yarn is made: the polylactic acid short fiber and the bleached cotton yarn and the bleached cotton fiber obtained in part of step 1 are blended and twisted according to different mass ratios to obtain the first blended spinning ratio and different twist. blended yarn.

[0039] (3) The second blended yarn is made: the polylactic acid fiber and the bleached cotton yarn obtained in part of the first step and the bleached cotton fiber are blended, drawn or twisted and twisted according to different mass ratios to obtain different blending ratios and a second blended yarn with a different twist.

[0040] (4) Differential structure d...

Embodiment 1

[0062] This embodiment provides a preparation method of easily degradable differentiated excipients.

[0063] (1) Pre-treatment: The long-staple cotton yarn produced in Xinjiang of 20s / 2~100s / 2 is used for degreasing, bleaching, dehydration and drying in a relaxed state with a hank dyeing equipment, so that the long-staple cotton yarn is fully retracted to obtain low shrinkage rate of bleached cotton yarn.

[0064] (2) Production of the first blended yarn: the 10-45% bleached cotton yarn obtained in step 1 is blended and twisted with 55-90% polylactic acid short fibers to obtain polylactic acid containing 55%, 60%, 65%, Eight blended 20S / 2-100S / 2 first blended yarns with different contents of 70%, 75%, 80%, 85%, and 90% are spun, and the obtained first blended yarn has a twist of 150-300 twists.

[0065] (3) Production of the second blended yarn: the 5-55% bleached cotton yarn obtained in step 1 is blended with 45-95% polylactic acid fiber, and then drawn and twisted with the...

Embodiment 2

[0105] This embodiment provides a preparation method of easily degradable differentiated excipients.

[0106] The difference between the method of this embodiment and the embodiment 1 is that in step 1, ordinary 20s / 2~100s / 2 cotton yarn will be used for degreasing, bleaching, dehydration, and drying to obtain bleached cotton yarn, and the rest are the same.

[0107] Effect and test:

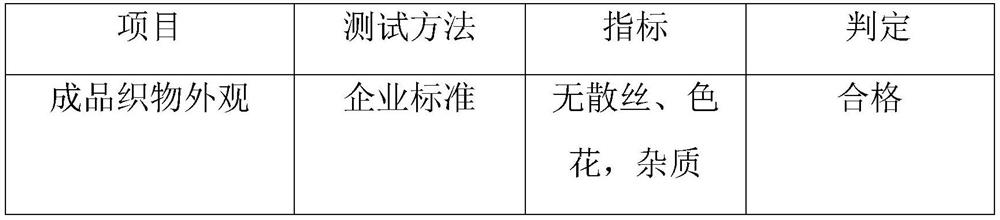

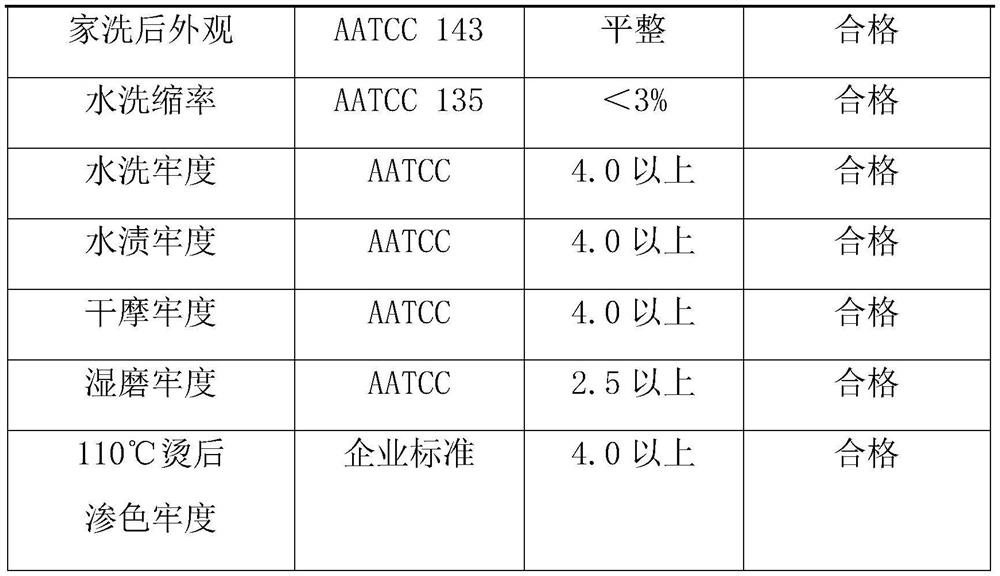

[0108] The appearance effect and color fastness of the obtained finished fabrics were tested, and the testing methods and standards are shown in Table 3 below.

[0109] table 3

[0110]

[0111]

[0112] During weaving, when the yarn count is 80S / 2~100S / S, warp breakage is easy to occur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com