leveler

A twist leveler and adjuster seat technology, applied in textiles and papermaking, etc., can solve the problems of difficult control of surface roughness, increased difficulty of guide wheel processing, large surface hardening treatment, etc., to achieve simple structure, strong twisting damage The effect of reduction and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

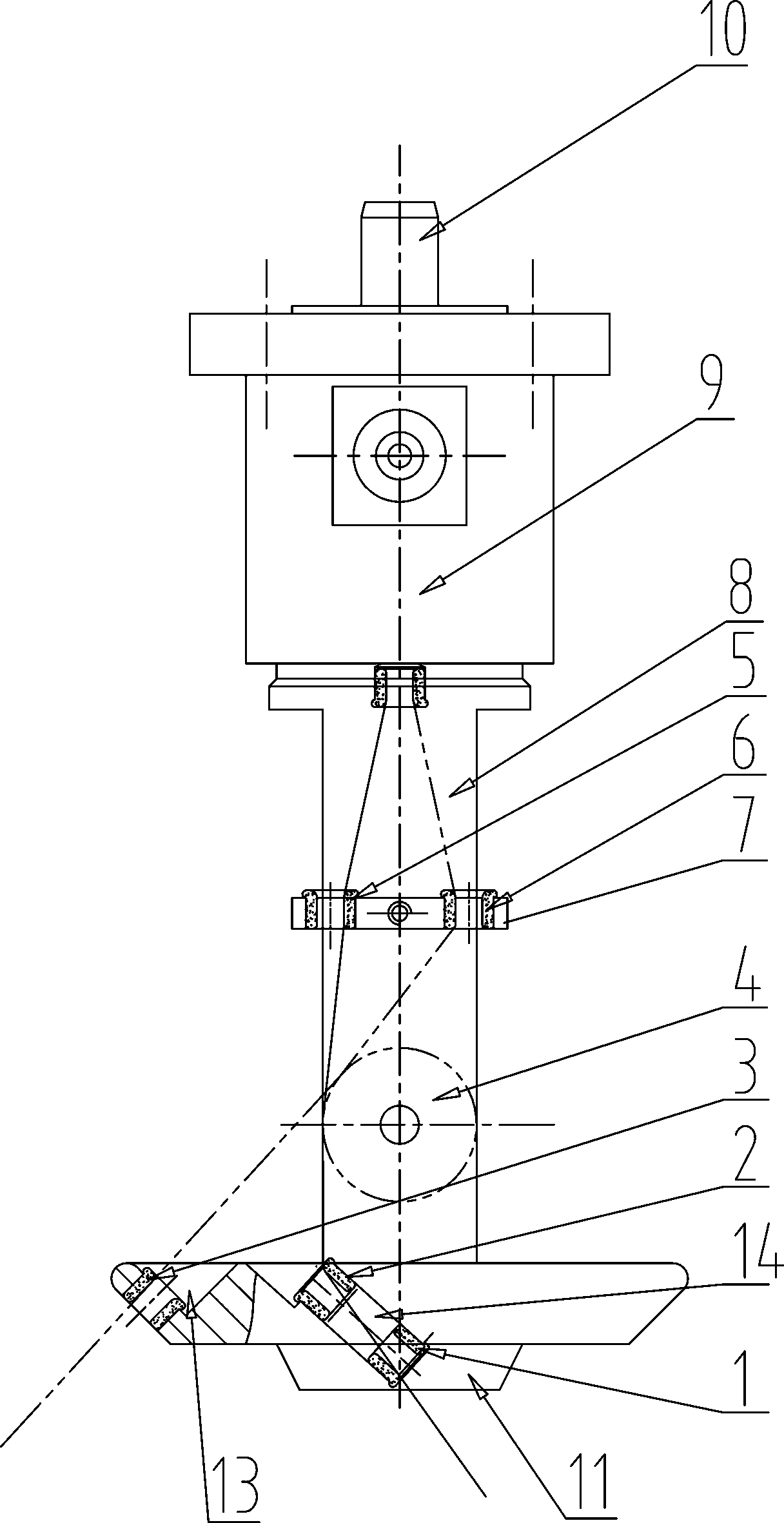

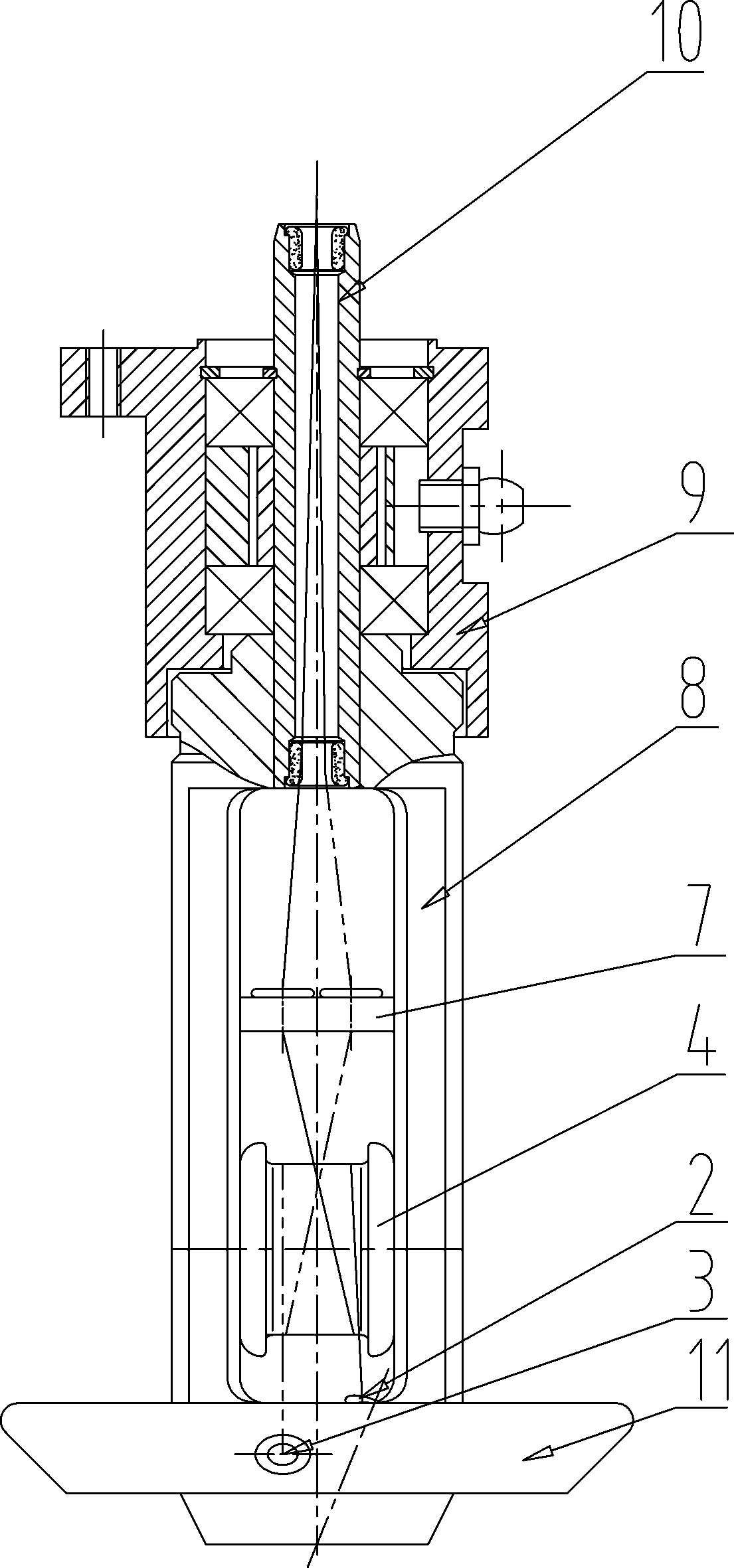

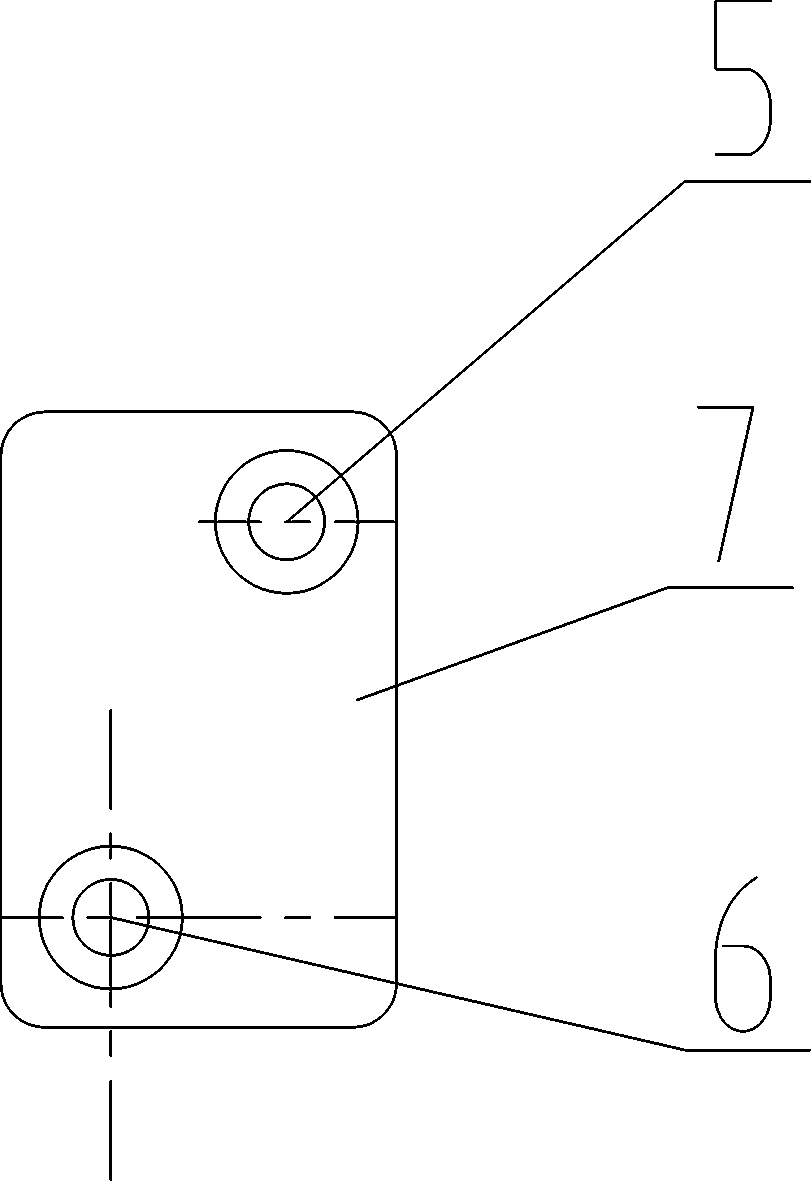

[0023] Such as Figure 1~4 Among them, a twist leveler includes a twist leveler frame 8, a balance plate 11 is provided at the bottom of the twist leveler frame 8, a combination roller 4 is arranged inside the twist leveler frame 8, and a yarn guide is fixed above the combination roller 4 plate 7, the fourth ceramic ring 5 and the fifth ceramic ring 6 which are independent of each other are arranged on the yarn guide plate 7. With this structure, the inner and outer yarns on the combination roller 4 are independent from each other and can not rub against each other. Simultaneously, the vibration of the ply yarn in the yarn guide tube 10 is reduced or eliminated.

[0024] The preferred solution is as figure 1 , 2 Among them, the yarn guide plate 7 is located in the hollow part inside the twist leveler frame 8, and the yarn guide plate 7 is arranged horizontally. The main effect of this solution is to reduce or eliminate the trembling of the ply yarn in the yarn guide tube 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com