Vertical dry anaerobic system adopting bottom feeding and top discharging

A dry anaerobic and feeding technology, which is applied in the methods of sampling biological materials, sterilization methods, biochemical equipment and methods, etc., can solve the problems of high pressure in the tank, hindering the production of biogas from fermentation, and potential safety hazards. , to achieve the effect of preventing sedimentation and expanding the range of feed moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

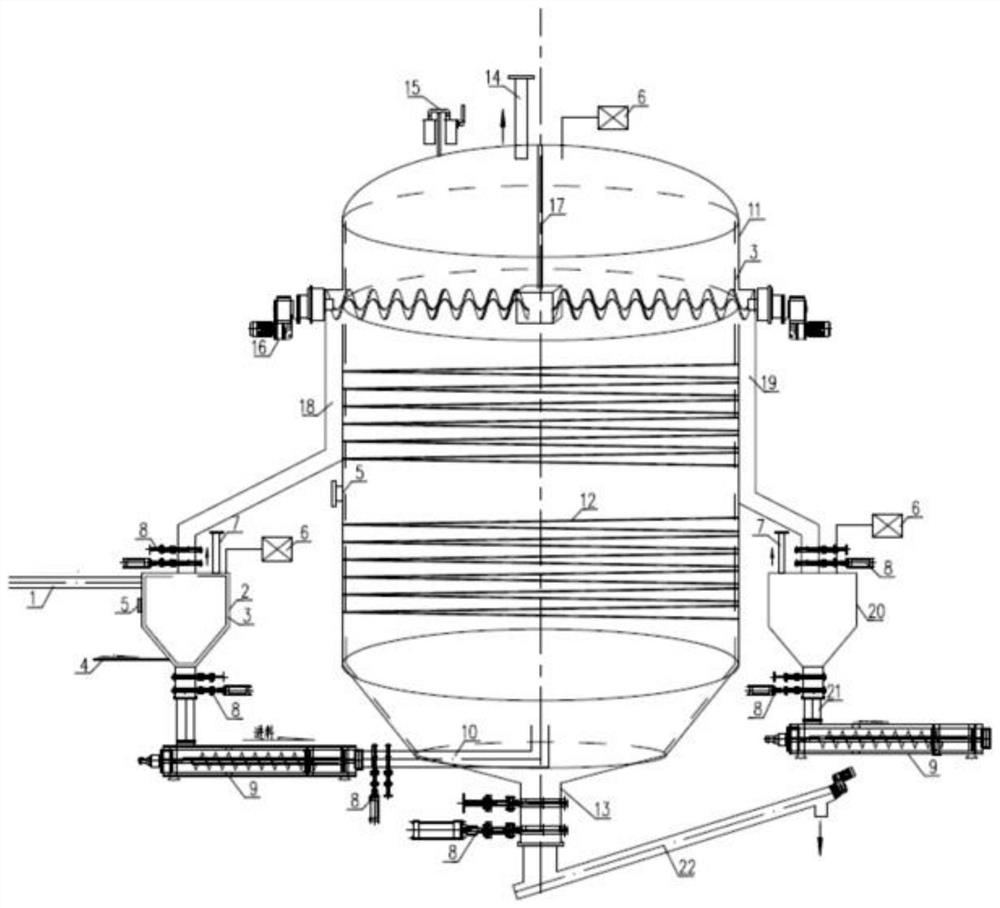

[0022] As shown in the figure, the present invention provides a vertical dry anaerobic system with bottom feed and top discharge, which is composed of feed reverse mixing tank 2 , anaerobic fermentation tank 11 , discharge tank 20 and sand discharge device 22 .

[0023] The upper part of the side wall of the feed reverse mixing tank 2 is connected to the raw material feed pipe 1, the bottom of the side wall is connected to the steam pipe 4 for heating the material in the tank, and the middle part of the side wall is provided with a temperature sensor 5. The bottom of the feed anti-mixing tank 2 is connected to the feed plunger pump 9 through a pipeline, and a double-knife gate valve 8 is installed on the pipeline, and an odor pipe 7 with a diameter of not less than DN50 and a radar level gauge are installed on the top of the feed anti-mixing tank...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com