A kind of fracturing proppant with corundum-anorthite as main crystal phase and preparation method

A fracturing proppant, anorthite technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc. It can ensure the strength and surface hardness, realize the resource utilization of solid waste, and reduce the cost of raw materials.

Active Publication Date: 2022-05-31

洛阳赛罗帕陶瓷科技有限公司 +1

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, with the dwindling of high-quality bauxite resources, the adjustment of national industrial policies and the increasingly fierce market competition, ceramsite proppant manufacturers are no longer allowed to use high-grade high-quality bauxite raw materials, nor can they afford them. resources, so we can only use more low-grade bauxite, and even some industrial solid waste as the main raw material to produce ceramsite proppant

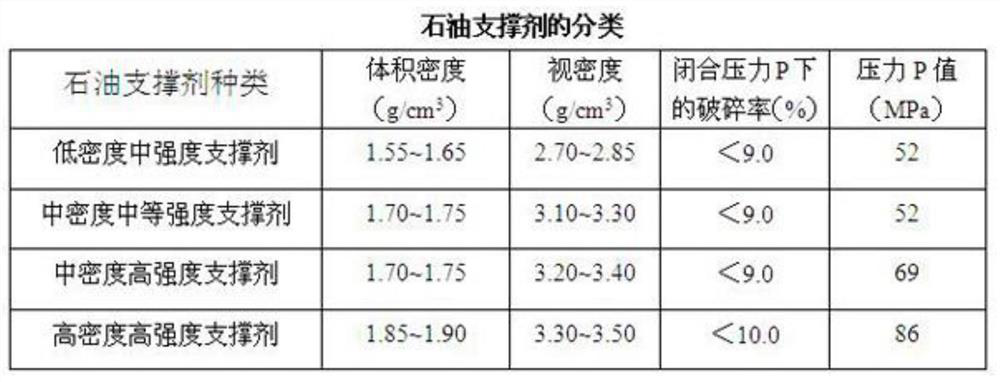

[0005] Although there are many types of proppant developed in China at present, covering the figure 1 The various types shown, but as far as high-strength proppants are concerned, most of them are high-density types, and very few high-strength proppants with medium and low densities

Moreover, even high-strength proppants with medium and low densities still have various problems, such as: or there are many types of raw materials used, the price is expensive, or the production process is complicated, the power consumption is large, or the firing temperature is high and the firing cycle is long. Long, high energy consumption per unit of product, etc.

[0006] For example, a medium-density, high-strength proppant preparation method disclosed in the invention patent CN103525396A, although medium and low-grade bauxite raw materials are used for production, but the disadvantages of this method are also very prominent: First, there are many types of raw materials used , including expensive manganese oxide powder with an amount of 2-6%; the second is that the production process is relatively complicated, and the bauxite raw material needs to be pre-fired at 800-1100°C for 1-3 hours; the third is the firing of the product The temperature is also high (up to 1320-1360°C), and the bauxite is pre-burned, so the energy consumption per unit product is too large; the fourth is that the grinding fineness of the batch material is required to reach 600 mesh, which will inevitably cause dust. Grinding consumes a lot of electricity; the fifth is the bulk density of the proppant (1.67-1.79g / cm 3 ) and apparent density (3.15-3.30g / cm 3 ) is too large

[0007] Another example is that the invention patent CN102952537A discloses a medium-density ceramsite proppant and its preparation method. Although the compressive strength of the product is satisfactory (69MPa breakage rate3 ) and apparent density (3.19-3.20g / cm 3 ) is also too large

[0008] Another example is that the invention patent of CN107266045A with the application publication number has announced a kind of corundum-mullite ceramsite proppant and preparation method thereof, although the raw material kind that it adopts is few, the main material bauxite grade is lower (Al 2 o 3 content is 60-63%), and the production process is simple and mature, but there are also three shortcomings: (1) the amount of water added during the granulation of the proppant is large (reaching 14-19% of the mass of the batch), resulting in the water content of the semi-finished product (2) The firing temperature of the proppant is high (1300-1450°C), and the firing cycle is long (4-5h), so the heat treatment (drying + firing) energy consumption per unit product is high (3) The quality stability of the proppant finished product is poor, and its bulk density (1.64-1.83g / cm 3 ), apparent density (3.10-3.33g / cm 3 ) and the crushing rate (3.3-6.4%) under the closing pressure of 69MPa fluctuate greatly

So far, no corundum-anorthite fracturing proppant products have been developed and applied

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

A fracturing proppant with corundum-anorthite as the main crystal phase and its preparation method, the main crystal phase of which is composed of corundum and anorthite, and fired from grade II bauxite, proppant waste material and composite additives The composite additive is made by mixing ordinary calcium aluminate cement and wollastonite in an equal weight ratio. The invention avoids the use of conventional expensive mineralizer manganese oxide powder, not only promotes the formation of a large amount of low-density, high-strength anorthite crystal phases, obtains excellent comprehensive performance, but also reduces the firing temperature and shortens the holding time , at the same time, the amount of water added to the molding is less, and the moisture content of the semi-finished product is low, which not only reduces the drying energy consumption of the proppant, but also ensures the strength and surface hardness of the proppant raw pellets, thereby preventing the raw pellets from being damaged during the transportation and drying process. De-powdering occurs, leading to disadvantages such as rough surface and reduced sphericity. In addition, the utilization of waste proppant materials realizes the recycling of solid waste and reduces the cost of raw materials for production.

Description

A fracturing proppant with corundum-anorthite as the main crystal phase and preparation method thereof technical field The present invention relates to the sintered solid ceramsite proppant used in oil and gas well fracturing technology, specifically a kind of A fracturing proppant with jade-anorthite as the main crystal phase and a preparation method thereof. Background technique [0002] Hydraulic fracturing technology has been widely used in oil and gas extraction operations. In the implementation of this technology During the process, in order to prevent the formation of fractures from re-closing under formation pressure and block the passage of oil and gas, high-strength The granular proppant is brought into the fractures of the oil well rock formation by the fracturing fluid, so that the fractures are propped up, thereby forming a certain conductivity. Powerful oil flow channel. Therefore, as one of the key basic materials for the implementation of hydraulic fr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K8/80C04B35/10

CPCC09K8/80C04B35/195C04B2235/3232C04B2235/36C04B2235/3222C04B2235/3454C04B2235/6562C04B2235/6565C04B2235/77C04B2235/96Y02P40/60

Inventor 陆昕昱张国强廖桂华朱艳红郭利朋张文辉

Owner 洛阳赛罗帕陶瓷科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com