Concrete test block manufacturing device and implementation method thereof

A technology for making devices and concrete, which is used in measuring devices, preparation of test samples, unloading devices, etc., can solve problems such as inability to meet requirements, and achieve the effects of ensuring integrity, improving smoothness, and uniform density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

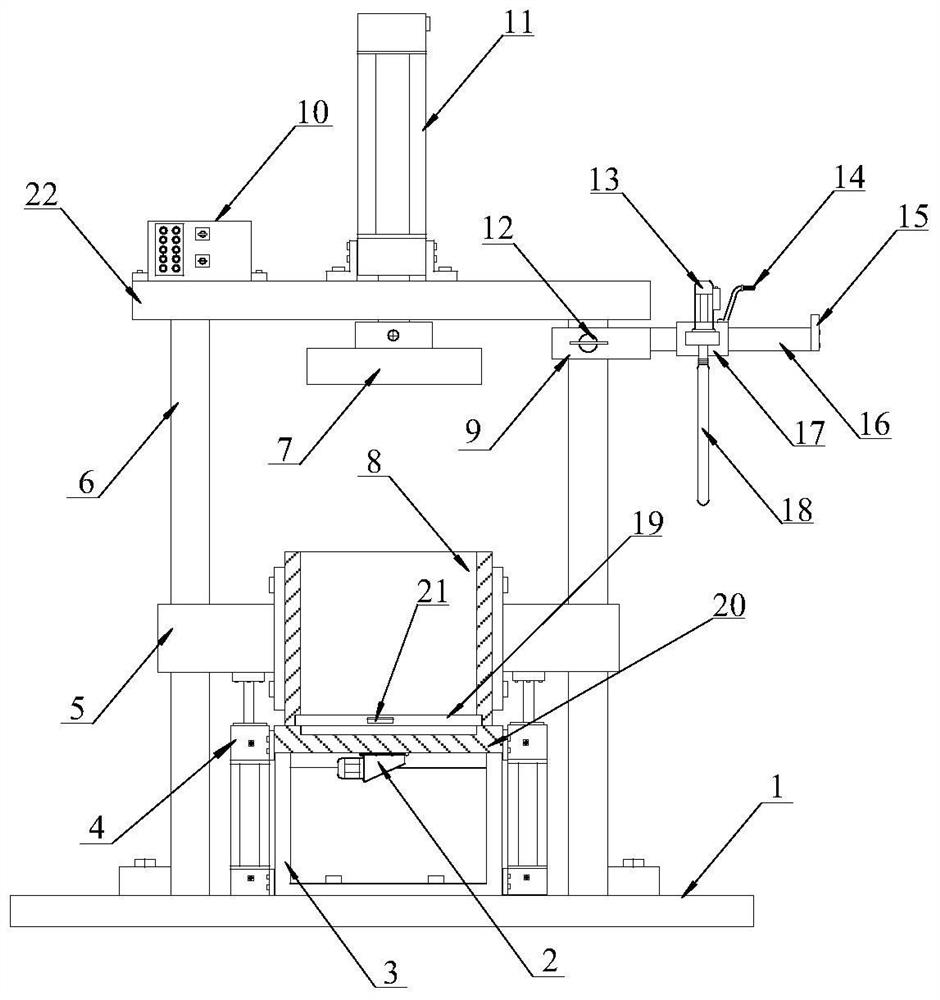

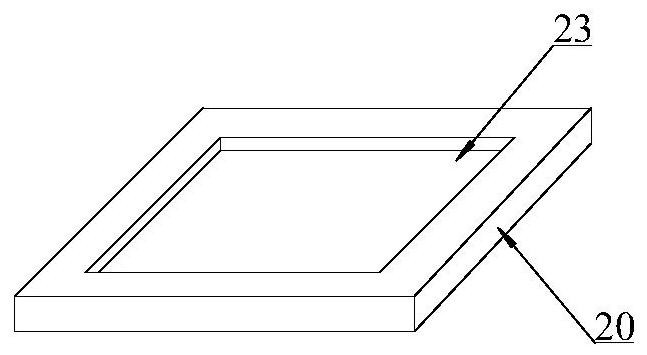

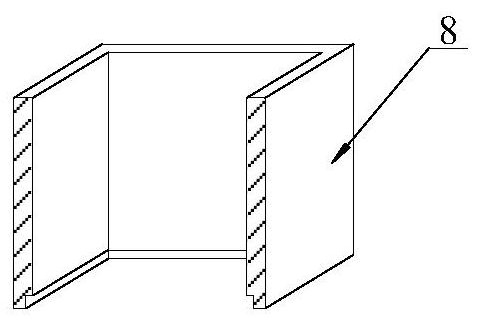

[0038] Such as figure 1 with 2 As shown, the concrete test block manufacturing device of the present invention includes a mounting base plate 1, a controller 10, a vertical slide bar 6, a flat pressing mechanism, a mold cavity 8, a mold cavity receiving platform, a lifting hydraulic cylinder 4, and a vibration mechanism . Wherein, the controller 10 is preferably implemented by using an existing mechanical control switch capable of outputting multiple control voltages in this embodiment, so this specification does not describe the structure of the controller 10 in detail. The controller 10 is respectively connected with the lifting hydraulic cylinder 4, the flat pressing mechanism and the vibrating mechanism, and controls the working states of the lifting hydraulic cylinder 4, the flat pressing mechanism and the vibrating mechanism.

[0039] During specific implementation, the installation substrate 1 can be fixed on the ground or on a preset slide plate for easy movement, wh...

Embodiment 2

[0046] The only difference between this embodiment and Embodiment 1 is that, as figure 1 As shown, a vibrator 2 is arranged on the lower surface of the platform 20 , and the controller 10 is connected to the vibrator 2 . The vibrator 2 can effectively reduce the gap between the concrete components and increase the density of the test block; at the same time, it can effectively eliminate the air bubbles on the contact surface between the concrete test block wall and the test mold cavity, avoid honeycomb and pitting, and improve The smoothness of the wall surface of the test block.

Embodiment 3

[0048] The implementation method of the concrete test block manufacturing device specifically comprises the following steps:

[0049] Step 1: Apply a layer of release liquid on each inner wall of the test cavity 8, and pour concrete into the test cavity 8 for the first time. Described release liquid is waste engine oil or release agent, and the type of release liquid can be set according to actual conditions, and the first time concrete pouring amount is 1 / 2 of the volume of trial mold cavity 8.

[0050] Step 2: Rotate and lower the vibrating mechanism, insert the vibrating rod 18 of the vibrating mechanism into the concrete in the test mold cavity 8 until the bottom of the test cavity 8 is 2 to 3 cm away, start the vibrating pump 13 to vibrate the concrete, and rotate the slide at a uniform speed. The seat 9 and the slider 17 move at a constant speed to vibrate the concrete from outside to inside for 30-40 minutes.

[0051] Step 3: After the vibration is completed, move the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com