Alkyl aromatic isomerization catalyst and preparation and application thereof

A technology for an alkyl aromatic hydrocarbon and a catalyst, which is applied to an alkyl aromatic hydrocarbon isomerization catalyst and the fields of preparation and application thereof, can solve the problems of low ethylbenzene conversion rate, unsatisfactory catalyst activity and selectivity, and difficulty in meeting production needs in overall performance. , to achieve the effect of high aromatic isomerization and de-side chain alkyl activity, high isomerization selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of catalyst of the present invention comprises the steps:

[0022] (1) Mix the sodium-type high-silicon five-membered ring zeolite and the macroporous pseudoboehmite evenly, add the aqueous solution of peptizer and knead, then shape, dry, and roast in the air at 400-650°C;

[0023] (2) Ion-exchange the solid calcined in step (1) with an ammonium salt solution, wash and dry the obtained solid, and impregnate it with a solution of a noble metal compound. After the impregnated solid is dried, it is roasted at 400-600° C. in air.

[0024] The method (1) step is carrier molding, mixing sodium-type high-silicon five-membered ring zeolite and large-pore pseudo-boehmite, adding an aqueous solution of peptizer and kneading, and the peptizer is preferably nitric acid, which is made after adding water The concentration of the nitric acid solution is preferably 1 to 5% by mass, more preferably 1.5 to 3.5% by mass. The addition amount of the nitric acid aqueo...

example 1

[0043] (1) Preparation of carrier

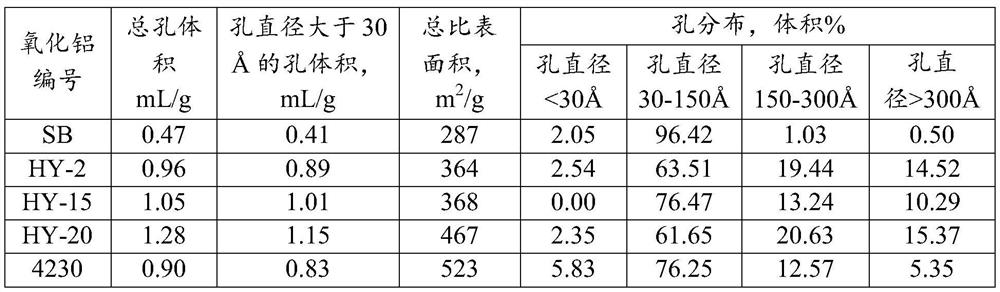

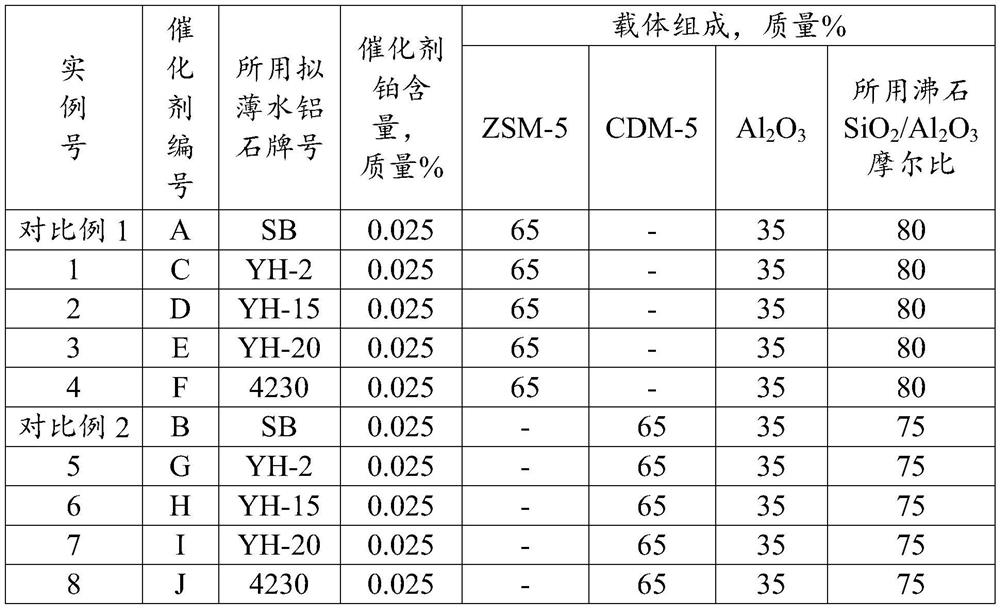

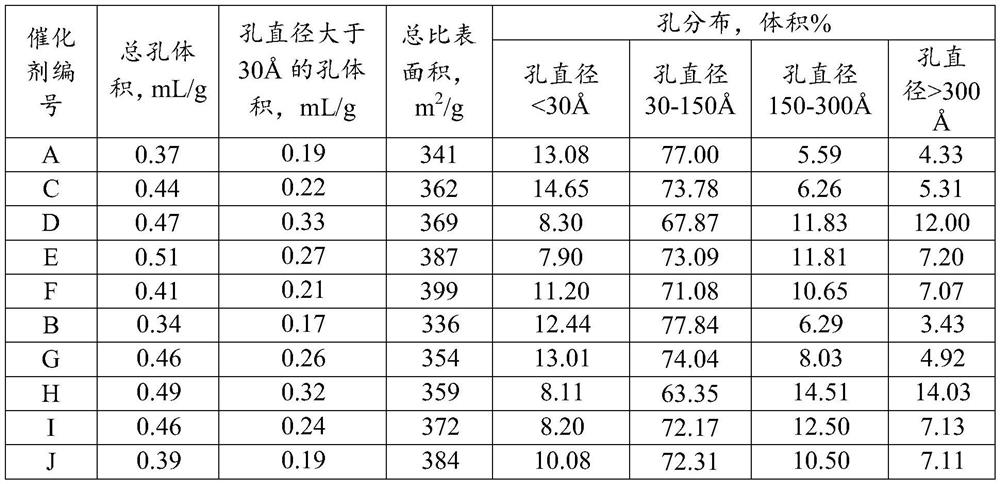

[0044] Take SiO 2 / Al 2 o 3 NaZSM-5 with a molar ratio of 80 and macroporous pseudoboehmite powder (manufactured by Fushun Petrochemical Company Catalyst Factory, brand YH-2) were mixed at a dry basis mass ratio of 65:35. After adding an aqueous solution of nitric acid with a concentration of 2% by mass, which accounts for 40% of the total mass of the powder, and kneading, extrusion molding, drying at 120°C for 2 hours, and roasting in air at 600°C for 3 hours to obtain a composite carrier, the macroporous pseudoboehmite The pore volume of YH-2 is 0.96mL / g, and the specific surface area is 364m 2 / g, the pore distribution is shown in Table 1.

[0045] (2) Preparation of catalyst

[0046] Get 100 grams of the composite carrier that (1) step makes, use the NH that concentration is 3 mass % 4 Cl aqueous solution carries out ion exchange at 90 DEG C for 2 hours, then immerses in 65 DEG C for 12 hours with chloroplatinic acid solution with ...

example 2

[0048] Prepare catalyzer by the method for example 1, difference is (1) in step, replace macroporous pseudo-boehmite YH-2 with macroporous pseudo-boehmite YH-15 (Fushun Petrochemical Company Catalyst Factory production), described macroporous pseudo-boehmite YH-2 Pseudoboehmite YH-15 has a pore volume of 1.05mL / g and a specific surface area of 368m 2 / g, the pore distribution is shown in Table 1, the composition of the prepared catalyst D is shown in Table 2, and the physical properties are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Hole diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com