Laminate structure and method for manufacturing same, and semiconductor device

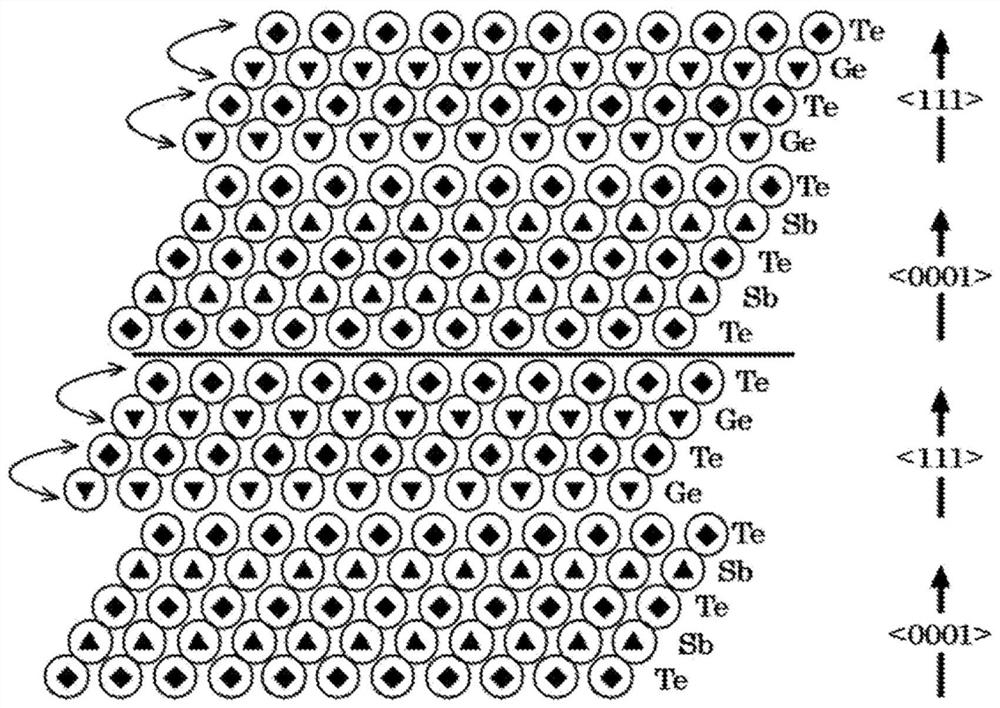

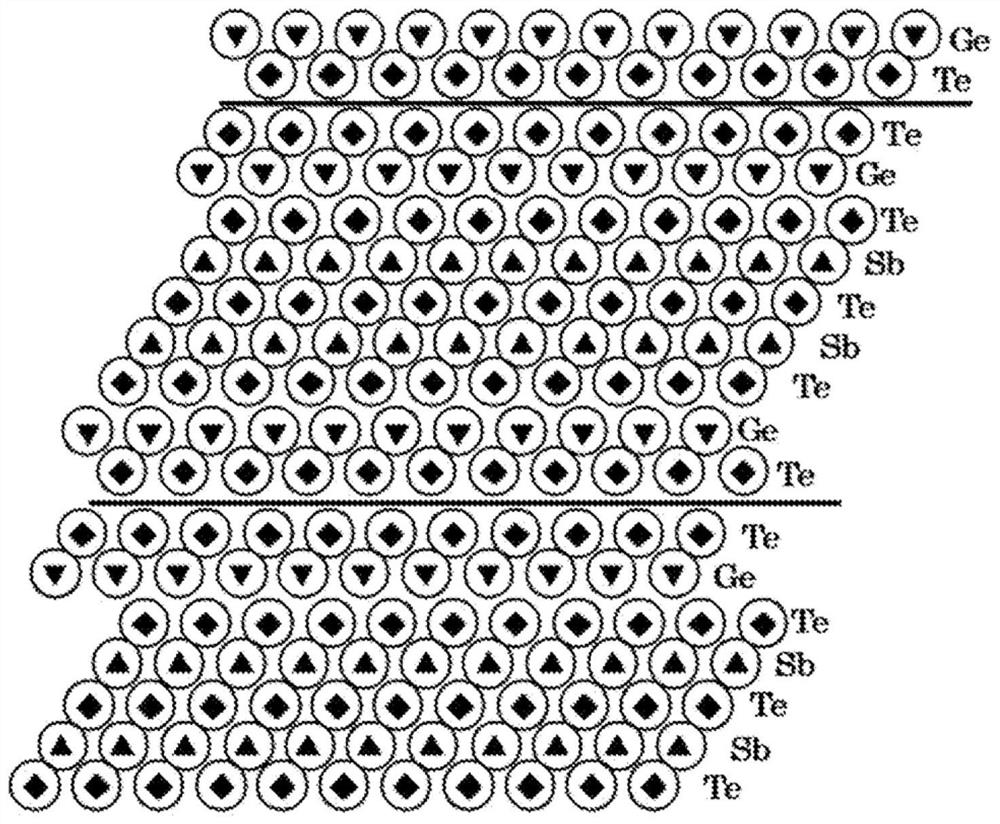

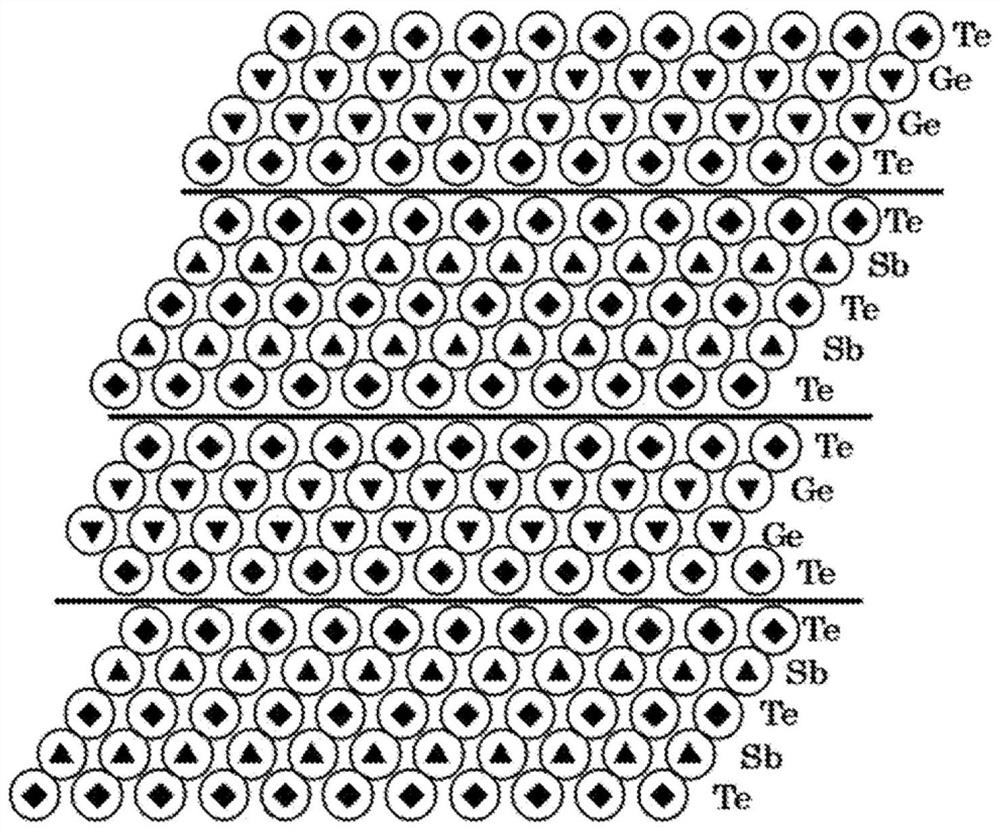

A manufacturing method and structure technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as inability to perform storage operations, inability to obtain Ge atom position information, etc., and achieve excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124]First, a sapphire substrate (manufactured by Shinko Co., Ltd.) with a thickness of 200 μm was moved to a sputtering device (manufactured by SHIBAURAMECHATRONICS Co., Ltd., 4EP-LL, equipped with three 3-inch targets). - 4 Pa, Ar film formation pressure of 0.5Pa, temperature of 25°C, and RF power of 100W, sputtering was performed using a silicon material (manufactured by Mitsubishi Materials Corporation, Si doped with B) as a target, and the sapphire substrate An amorphous silicon layer as a base layer was formed to a thickness of 40 nm.

[0125] Next, maintaining the vacuum back pressure, the film formation pressure of Ar was 0.5Pa, the temperature was 25°C, and the RF power was 20W. 2 Te 3 An alloy material (manufactured by Mitsubishi Materials Corporation, purity 99.9%) was used as a target for sputtering, and Sb was formed with a thickness of 3.0 nm on the amorphous silicon layer. 2 Te 3 Alloy layer (first layer). In addition, after forming, heating at 210°C makes...

Embodiment 2

[0148] By making the target material a GeTe alloy material with S atoms added (Ge 50 Te 47 S 3 ) was changed to GeTe alloy material with added Se atoms (Ge 50 Te 47 Se 3 , manufactured by Mitsubishi Materials Corporation, purity 99.9%), except that Se atoms were added to the GeTe alloy layer, the laminated structure of Example 2 was produced in the same manner as in Example 1.

[0149] The same structural analysis as in Example 1 was carried out on the laminated structure of Example 2. As a result, the same analysis results as in Example 1 were obtained, and it was confirmed that even when Se atoms were added instead of S atoms, a stable structure was obtained. A layered structure in which atoms are arranged can suppress the diffusion of Ge atoms.

Embodiment 3

[0161] in accordance with Figure 10 With the configuration of the semiconductor device 10 shown, the semiconductor device of the third embodiment is manufactured. Hereinafter, specific production conditions will be described. also, Figure 10 It is an explanatory diagram for explaining the configuration of the semiconductor device of the third embodiment.

[0162] As the structure on the bottom surface side of the laminated structure 18, SiO formed on the silicon substrate 11 is used. 2 In the layer 12, the structure of the lower electrode of the W layer 13 and the TiN layer 14 is laminated|stacked in this order. In addition, the diameter of the TiN layer 14 was 90 nm.

[0163]Except for changing the thickness from 3.0 nm to 5.0 nm, the Sb of the first layer in the laminated structure according to Example 1 2 Te 3 alloy layer, formed on the surface of the TiN layer 14 on which the structure is formed, containing Sb 2 Te 3 Alloy base layer 15.

[0164] Next, the GeTe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com