Manganese-based lithium-rich oxide positive electrode material, preparation method thereof, and electrochemical device applying manganese-based lithium-rich oxide positive electrode material

A positive electrode material, manganese-based lithium-rich technology, applied in the direction of electrochemical generators, circuits, electrical components, etc., can solve the problems of long reaction time and heat treatment time, shedding, complex process, etc., to improve the lithium ion diffusion capacity and rate Performance, prevention of falling off or damage, effect of reducing interface stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] A method for preparing a manganese-based lithium-rich oxide cathode material, comprising the steps of:

[0051] Step S1: providing a manganese-based lithium-rich oxide material.

[0052] In one embodiment, the chemical formula of the manganese-based lithium-rich oxide material is as follows: xLi 2 MnO 3 ·(1-x)LiTM y m (1-y) o 2 , 0<x<1, 0.9<Y<1, wherein TM mainly includes at least one of Ni, Co, and Mn, and M is at least one of Al, Fe, Mg, and Ti.

[0053] In an embodiment, the manganese-based lithium-rich oxide material may be a layered manganese-based lithium-rich oxide material.

[0054] Step S2: Mix the manganese-based lithium-rich oxide material with water or an aqueous solution containing highly oxidizing substances and add it into a closed container, stir evenly and heat-treat at a temperature range greater than 100° C. for 0.5 to 10 hours to obtain pretreatment mixture, wherein the water can be neutral water.

[0055] In one embodiment, the lithium ions (...

Embodiment 1

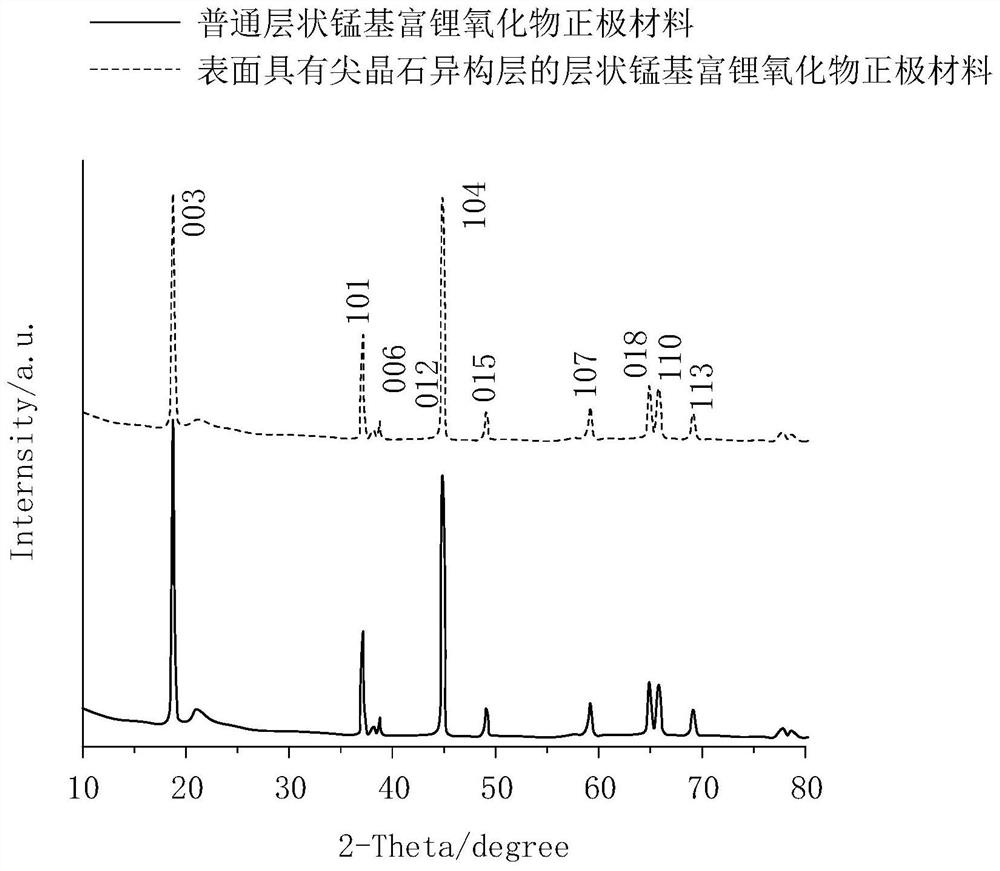

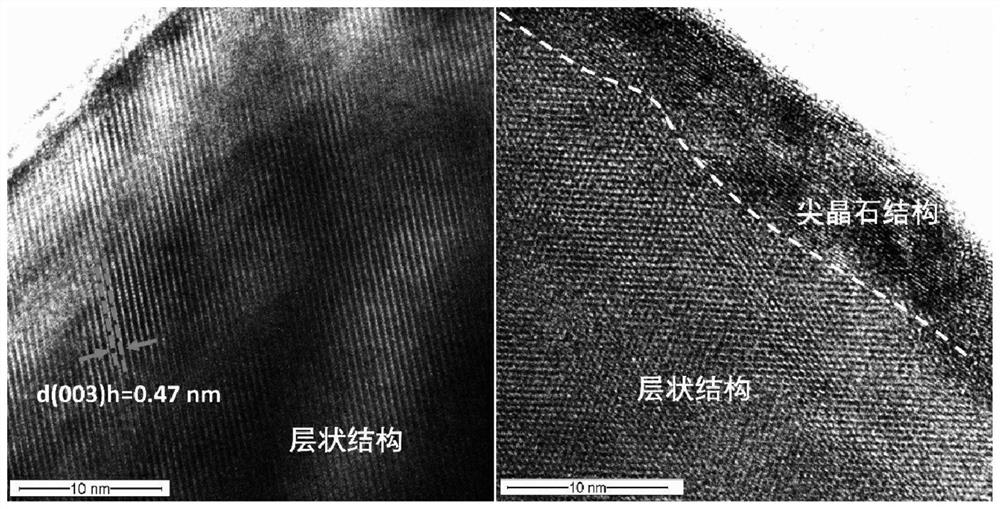

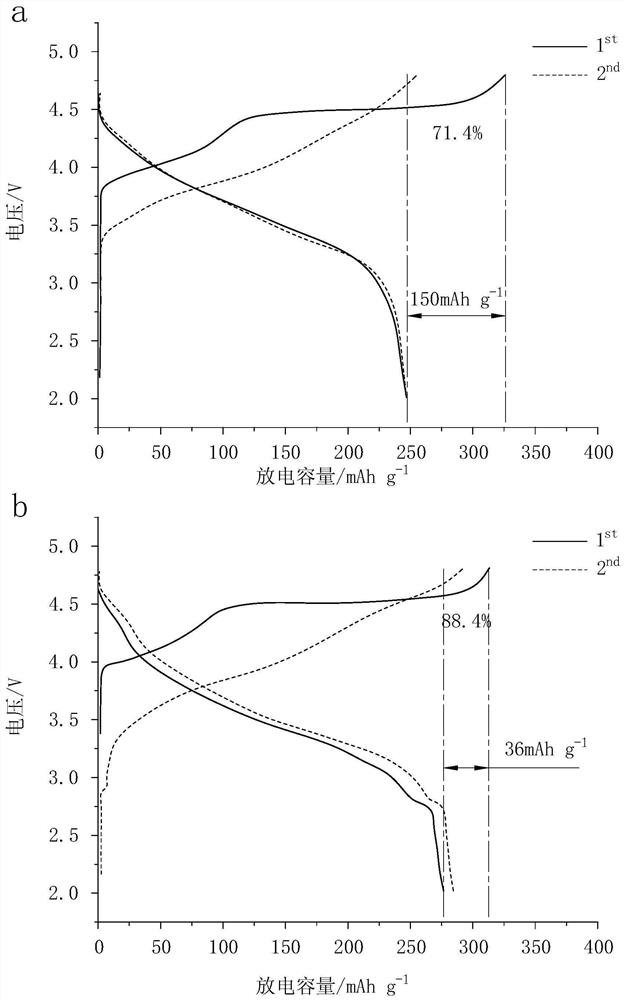

[0070] Add 1g of manganese-based lithium-rich oxide material to 35mL of deionized water, then stir, put the solid-liquid suspension into a closed high-temperature reaction kettle, and heat at 150°C for 10 hours to make the manganese-based lithium-rich oxide material A lithium-poor layer is formed on the surface layer, and a pretreatment mixture is obtained. Solid-liquid separation was performed on the pretreatment mixture to obtain the solid pretreatment, and the pretreatment was placed in an oven and dried at a temperature of 80° C. for 2 hours. Then the dried pre-treated material was put into a muffle furnace at 500°C for calcination for 3 hours to convert the layered lithium-poor layer on the surface of the pre-treated material into a spinel structure, and waited for the temperature of the muffle furnace to drop to room temperature before taking it out. A layered manganese-based lithium-rich oxide cathode material with a spinel phase heterogeneous layer on the surface is ob...

Embodiment 2

[0072] Add 0.5g of manganese-based lithium-rich oxide material to 35mL of deionized water, then stir, put the solid-liquid suspension into a closed high-temperature reactor, and heat at 150°C for 10 hours to make the manganese-based lithium-rich oxide material A lithium-poor layer is formed on the surface layer, and a pretreatment mixture is obtained. Solid-liquid separation was performed on the pretreatment mixture to obtain the solid pretreatment, and the pretreatment was placed in an oven and dried at a temperature of 80° C. for 2 hours. Then the dried pre-treated material was put into a muffle furnace at 500°C for calcination for 3 hours to convert the layered lithium-poor layer on the surface of the pre-treated material into a spinel structure, and waited for the temperature of the muffle furnace to drop to room temperature before taking it out. A layered manganese-based lithium-rich oxide cathode material with a spinel phase heterogeneous layer on the surface is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com