Spreading and baking all-in-one machine for frozen slices

A frozen section and integrated machine technology, which is applied in the field of medical machinery, can solve the problems of easy dust pollution, difficulty in removing pieces, affecting the experimental progress and experimental results, etc., and achieves the effect of reasonable operation route design, compact structure, and space saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings. Obviously, the described embodiments are only some embodiments of the present invention, rather than all implementations. example. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

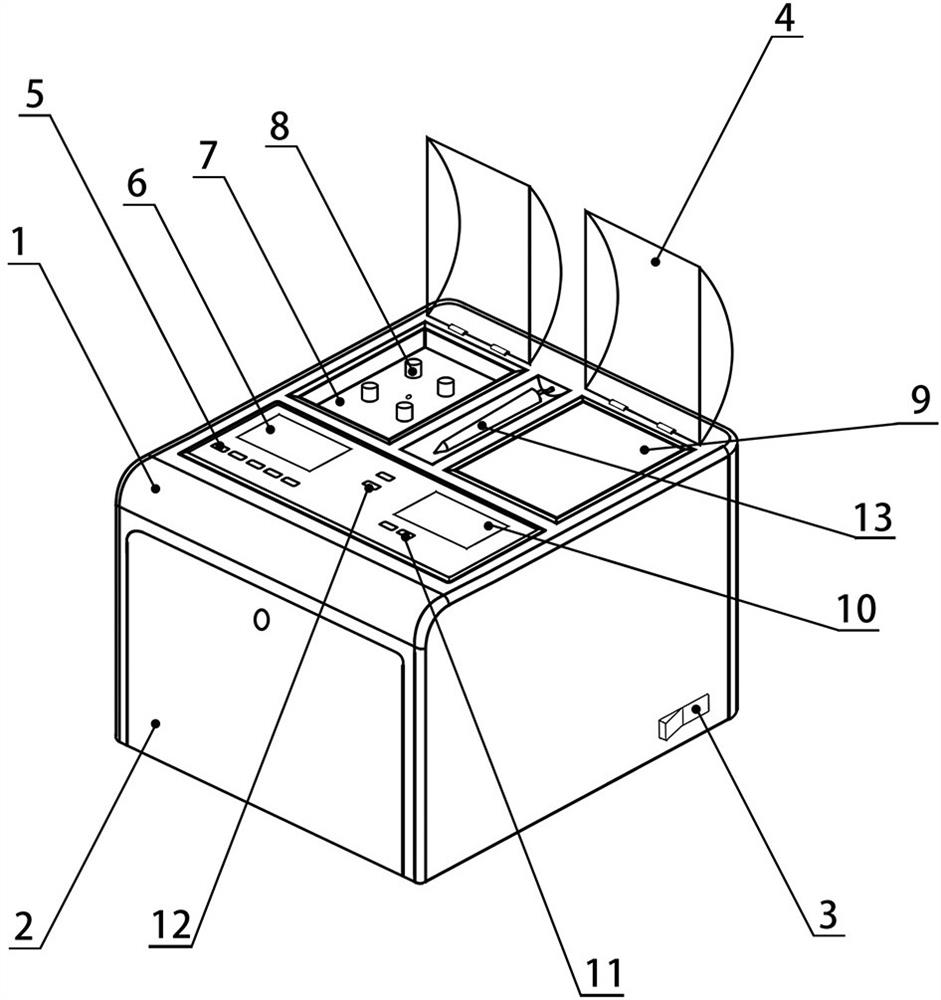

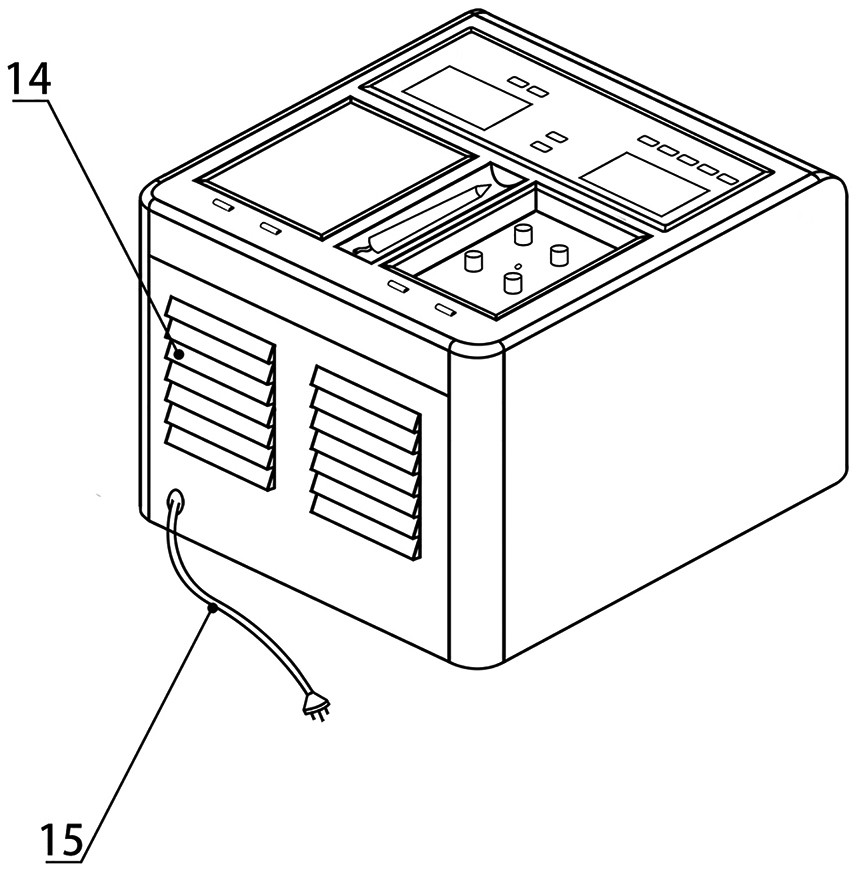

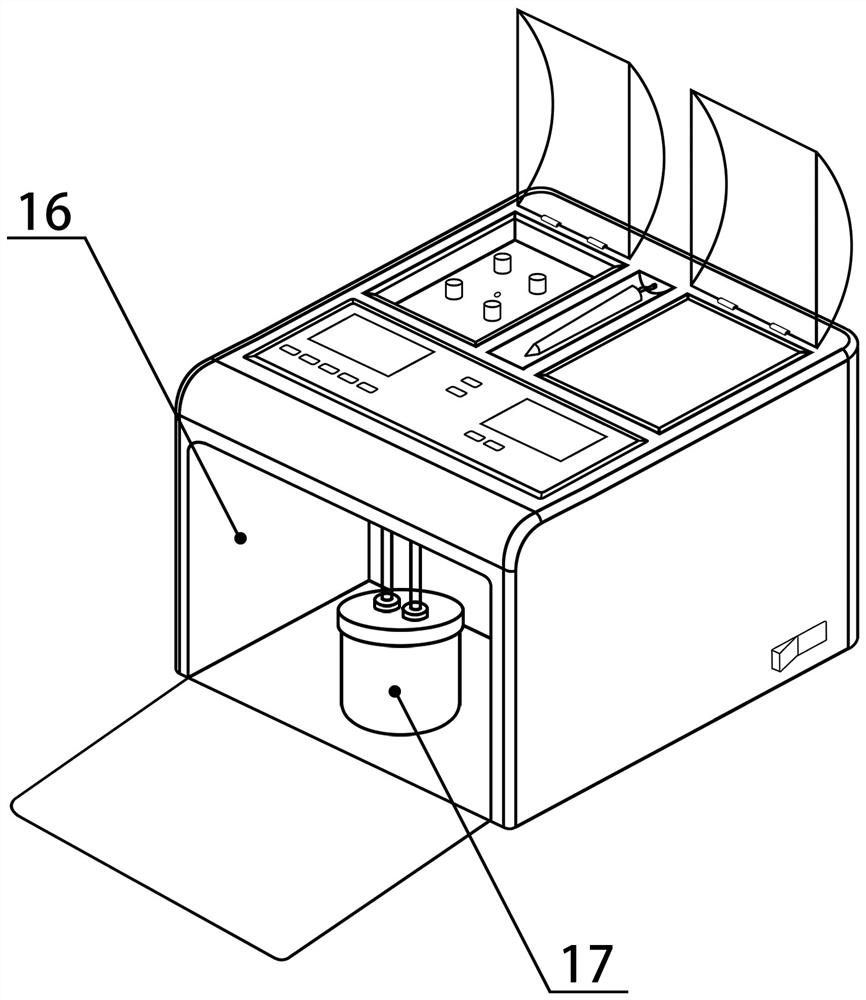

[0044] see Figure 1-7 As shown, a frozen slice spreading and roasting all-in-one machine of the present invention includes a body 1, the body 1 is composed of a spreading area 7, a movable magnetic suction glass table 8, an LCD screen 6 in the spreading area, and control buttons in the spreading area 5. Transparent plastic cover 4, micro liquid suction pen 13, suction pen control button 12, metal baking sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com