Synchronous tooth-shaped rope transmission device

A technology of rope transmission and tooth shape, which is applied in the direction of transmission devices, friction transmission devices, hoisting devices, etc., can solve the problems that non-parallel axes are not applicable, and synchronous toothed belts cannot realize the transmission of axes at any angle, so as to achieve large power transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

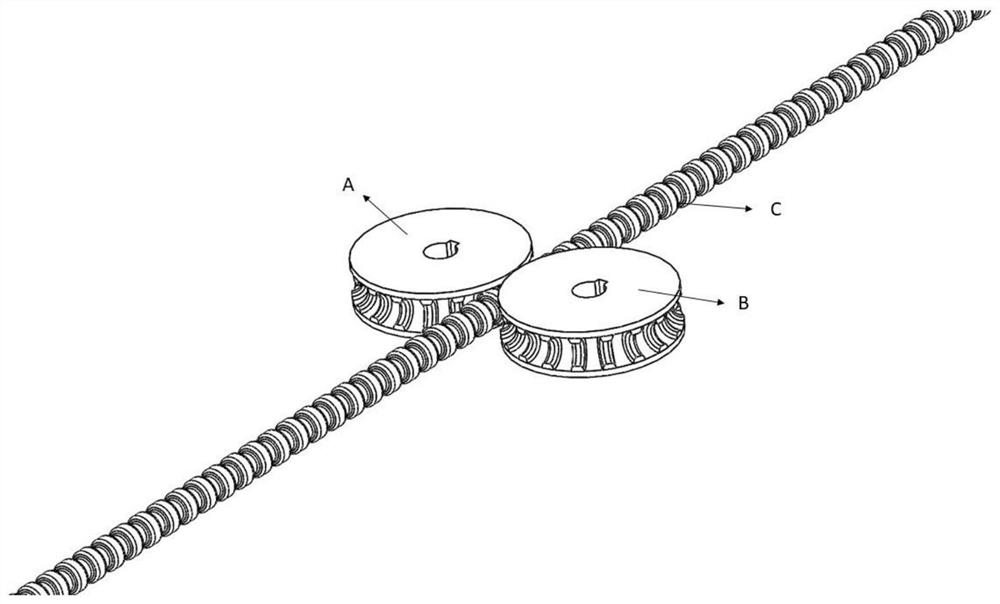

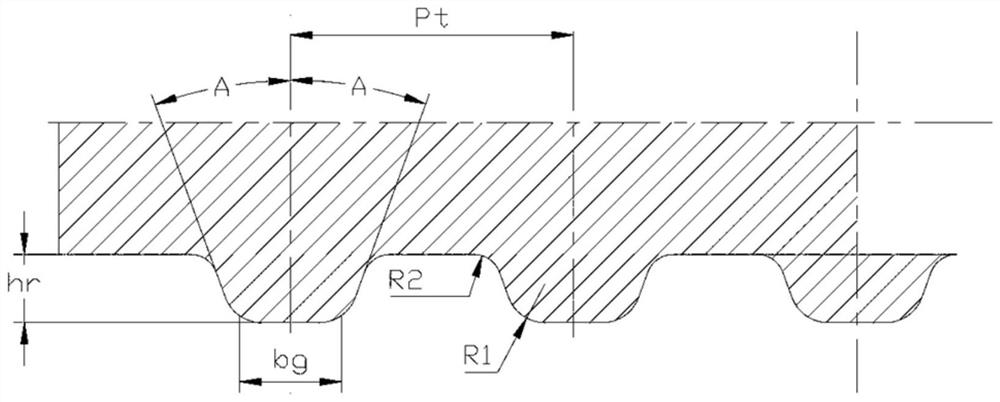

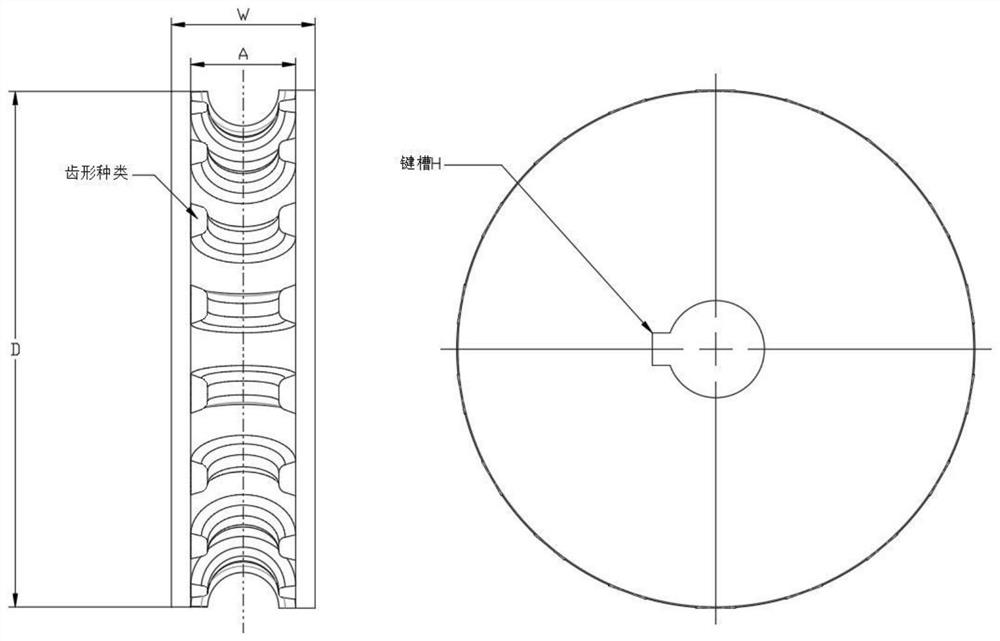

[0024] In the prior art, synchronous toothed belts are generally divided into trapezoidal toothed synchronous belts and circular arc toothed synchronous belts. for high speed transmission. The tooth shape of the arc-toothed synchronous belt is curved, so that the tooth height, tooth root thickness and tooth root fillet radius are larger, and the stress distribution state is better after loading, so as to avoid excessive concentration of tooth root stress and increase the tooth root The load level of the circular arc tooth synchronous belt is better, and the service life is longer. The teeth in the tooth layer of the trapezoidal tooth synchronous belt and the arc tooth synchronous belt are arranged on a plane, and the tooth grooves in the toothed pulley are arranged on a cylindrical surface, which can only be used for transmission with parallel axes. In the synchronous toothed rope and the synchronous toothed sheave of the present invention, the teeth arranged on the plane are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com