Polyester film protective film

A technology of polyester film and protective film, which is applied in the direction of pressure-sensitive film/sheet, film/sheet-shaped adhesive, ester copolymer adhesive, etc. It can solve the problems of low surface energy optical components, etc., and achieve both optical Improvement of performance and heat resistance, effect of preventing damage to electronic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

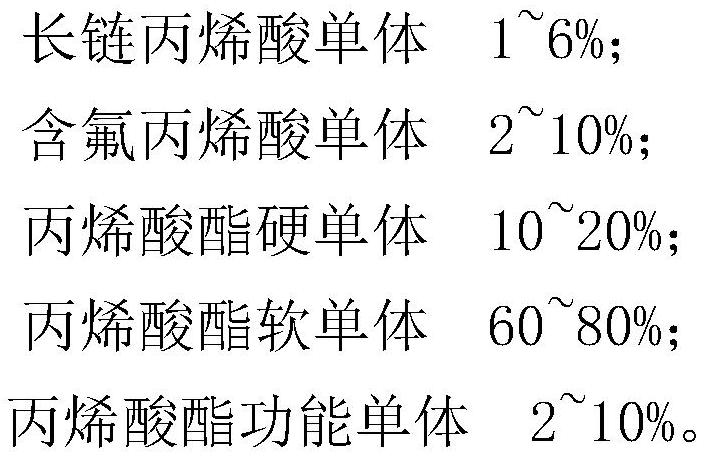

Method used

Image

Examples

Embodiment 1

[0056] Weigh 0.45g dodecyl acrylate, 1.5g octadecyl acrylate, 1.05g pentadecyl methacrylate, 2g dodecafluoroheptyl acrylate, 15g methyl methacrylate, 75g butyl acrylate , 1g of acrylic acid, 2g of methacrylic acid, and 2g of hydroxyethyl acrylate, the temperature was raised to 70°C. Evenly add 70g of initiator diluent dropwise, control the dropping time for 3 hours, and then keep warm for 2 hours. Continue to dropwise add 30g of the initiator diluent, control the dropwise addition time for 1 hour, and then keep the temperature for 1 hour. Then cool the synthesized resin to room temperature to obtain acrylate resin.

[0057] Weigh 30g of the above acrylate resin, 0.1g lithium trifluoromethanesulfonate, 0.5g Basionics LQ01, 0.5g AI4300-3T, 1gLupranate TDI-80, 1.5g Cymel303, 30g butyl acetate, 30g acetone, 20g toluene, mix After being uniform, a coating solution is obtained, the coating solution is coated on the surface of the polyester film, and after drying, a release film is...

Embodiment 2

[0059] Weigh 0.15g dodecyl acrylate, 2.5g octadecyl acrylate, 1.25g pentadecyl methacrylate, 3g perfluorooctyl ethyl acrylate, 5g dodecafluoroheptyl acrylate, 2g Octafluoropentyl acrylate, 8g vinyl acetate, 12g methyl methacrylate, 60g isooctyl acrylate, 2g methacrylic acid, 3g hydroxyethyl acrylate, 1g hydroxypropyl acrylate, heated up to 75°C. Evenly add 70g of initiator diluent dropwise, control the dropping time for 3 hours, and then keep warm for 2 hours. Continue to dropwise add 30g of the initiator diluent, control the dropwise addition time for 1 hour, and then keep the temperature for 1 hour. Then cool the synthesized resin to room temperature to obtain acrylate resin.

[0060] Weigh 30g of the above acrylate resin, 0.5g lithium perfluoroethanesulfonamide, 0.5g Basionics LQ01, 0.5g AI4300-3T, 1g N3300, 1.5g Maprenal MF 915, 30g butyl acetate, 30g acetone, 20g toluene, mix After being uniform, a coating solution is obtained, the coating solution is coated on the surf...

Embodiment 3

[0062] Weigh 1g octadecyl acrylate, 5.8g dodecafluoroheptyl acrylate, 1.2g octafluoropentyl acrylate, 10g vinyl acetate, 40g butyl acrylate, 40g isooctyl acrylate, 2g hydroxyethyl acrylate, heat up to 80°C. Evenly add 70g of initiator diluent dropwise, control the dropping time for 3 hours, and then keep warm for 2 hours. Continue to dropwise add 30g of the initiator diluent, control the dropwise addition time for 1 hour, and then keep the temperature for 1 hour. Then the synthesized resin is cooled to room temperature to obtain acrylate resin.

[0063] Weigh 40g of the above-mentioned acrylate resin, 0.2g lithium trifluoromethanesulfonate, 1g AI4300-3T, 1.5g Maprenal MF 915, 30g ethyl acetate, 20g methyl ethyl ketone, 10g cyclohexanone, and mix them uniformly to obtain a coating solution. The coating solution is coated on the surface of the polyester film, and after being dried, a release film is pasted on the surface of the pressure-sensitive adhesive to obtain a protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com