Temperature-controlled solar brine treatment system

A technology of temperature control system and solar light, applied in water/sewage treatment, water treatment parameter control, water/sludge/sewage treatment, etc., can solve the problem of reducing natural convection heating efficiency, difficulty in reaching gasification temperature, and stagnation at the bottom To achieve the effect of enhancing natural convection heat transfer efficiency, low manufacturing cost, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

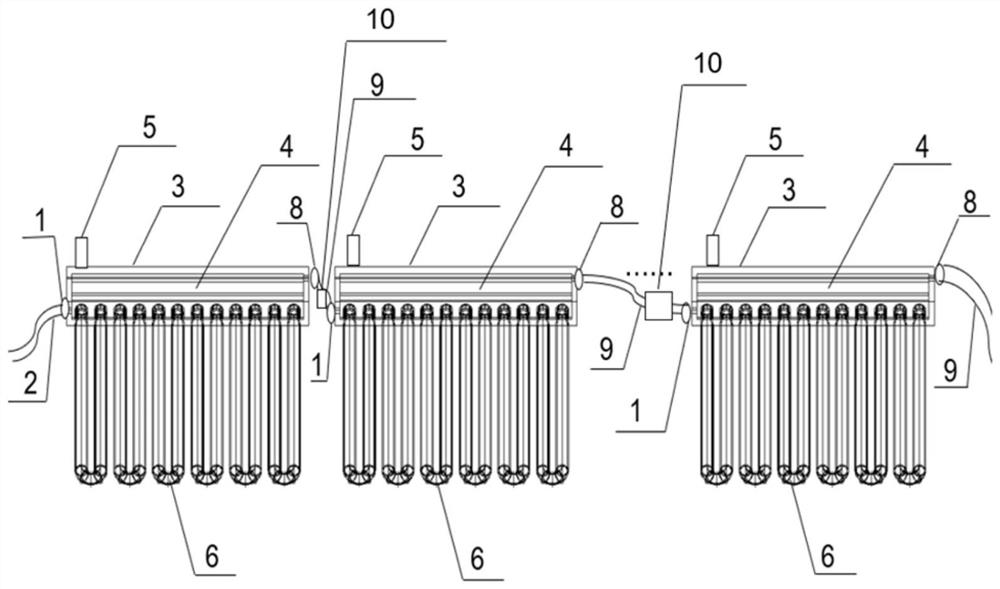

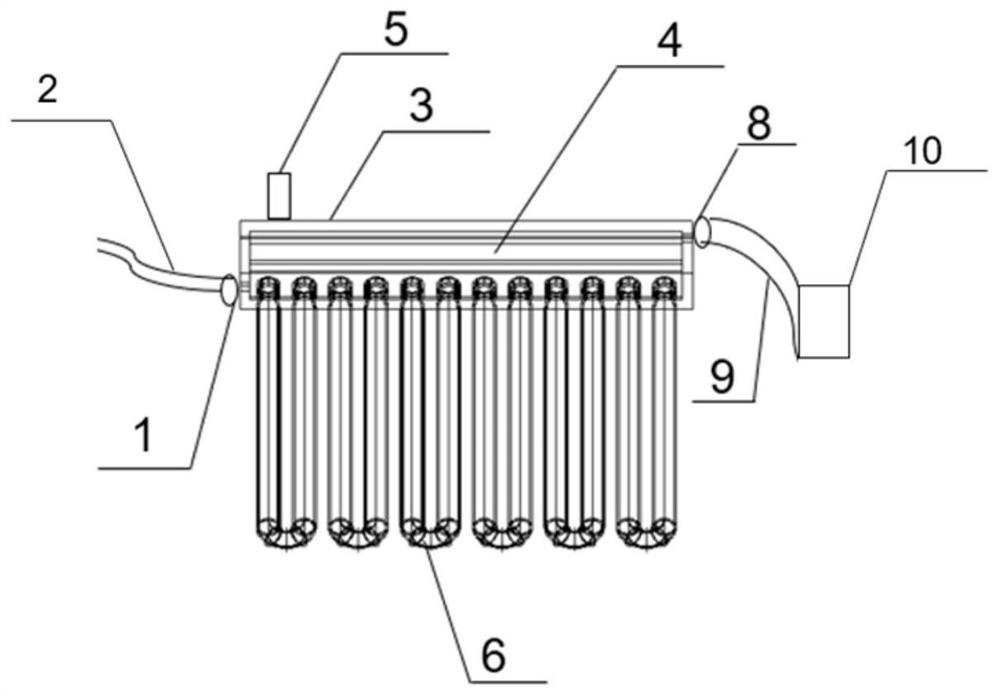

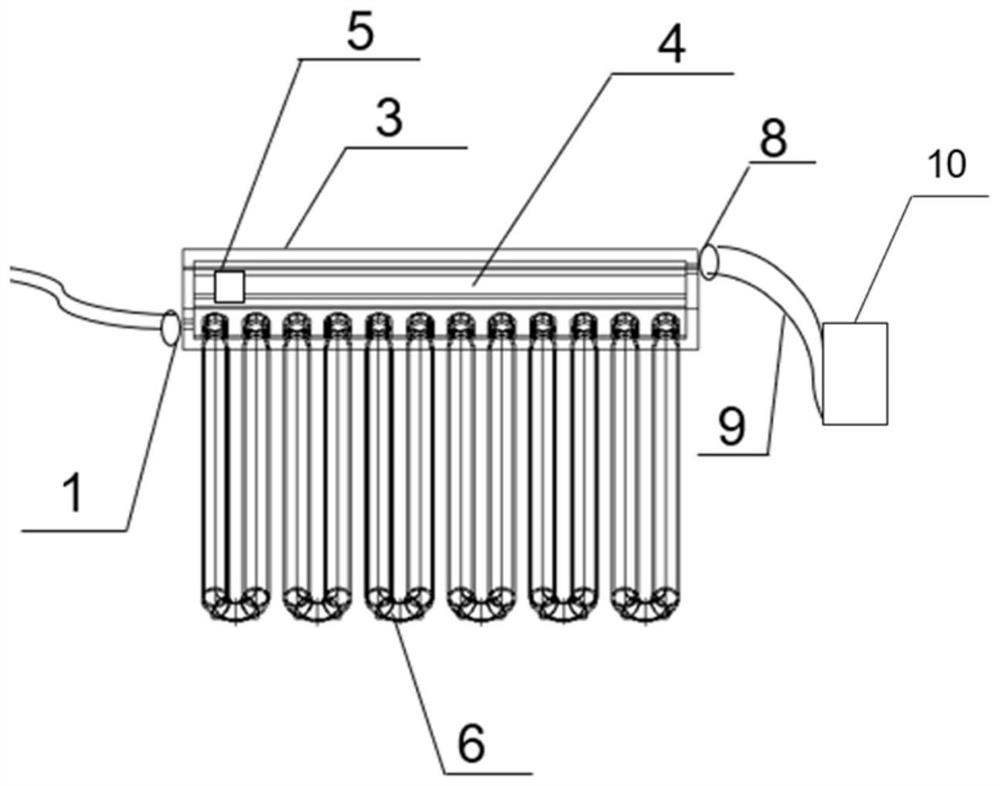

[0024] Such as figure 1 As shown, a temperature-controlled solar brine treatment system consists of multiple segmented solar heating units. The heating unit structure is as Figure 2-5 As shown, it includes water inlet 1, water inlet pipe 2, fan-shaped heat preservation water tank 3, exhaust valve 5, U-shaped vacuum heat collector 6, bracket 7, temperature control system 8, water outlet, water outlet valve 13, water inlet valve 17, etc. . Both sides of the fan-shaped thermal insulation water tank 3 are respectively provided with a water inlet 1 and a water outlet. The water inlet 1 is located at the bottom of the side of the fan-shaped thermal insulation water tank 3, so that an appropriate amount of salt water flows into the fan-shaped thermal insulation water tank 3 through the water inlet 1. The water outlet is located in the fan-shaped thermal insulation water tank. 3. On the upper part of the side, the area corresponding to the central angle of the fan-shaped thermal in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com