Automatic printing and conveying device for tempered glass

A technology for conveying equipment and tempered glass, which is applied to conveying objects, lighting and heating equipment, printing, etc. It can solve problems such as low production efficiency, easily damaged glass pieces, and damaged flower surfaces, so as to improve the product qualification rate and improve the quality of the product. Positive precision, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

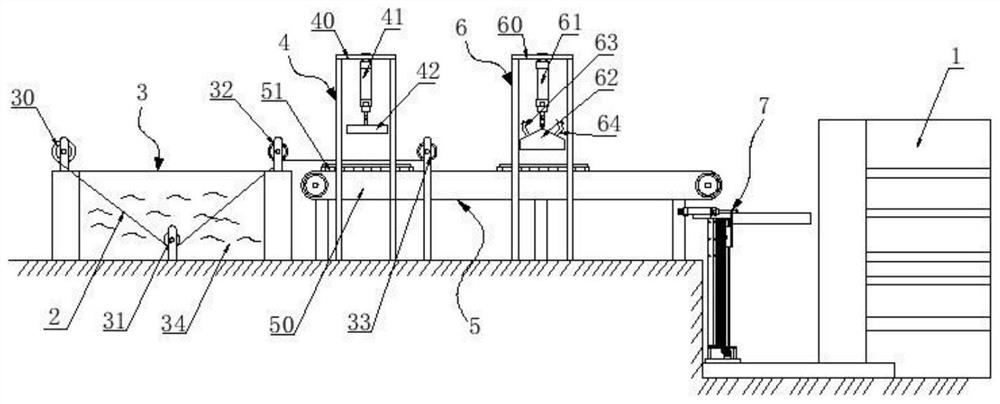

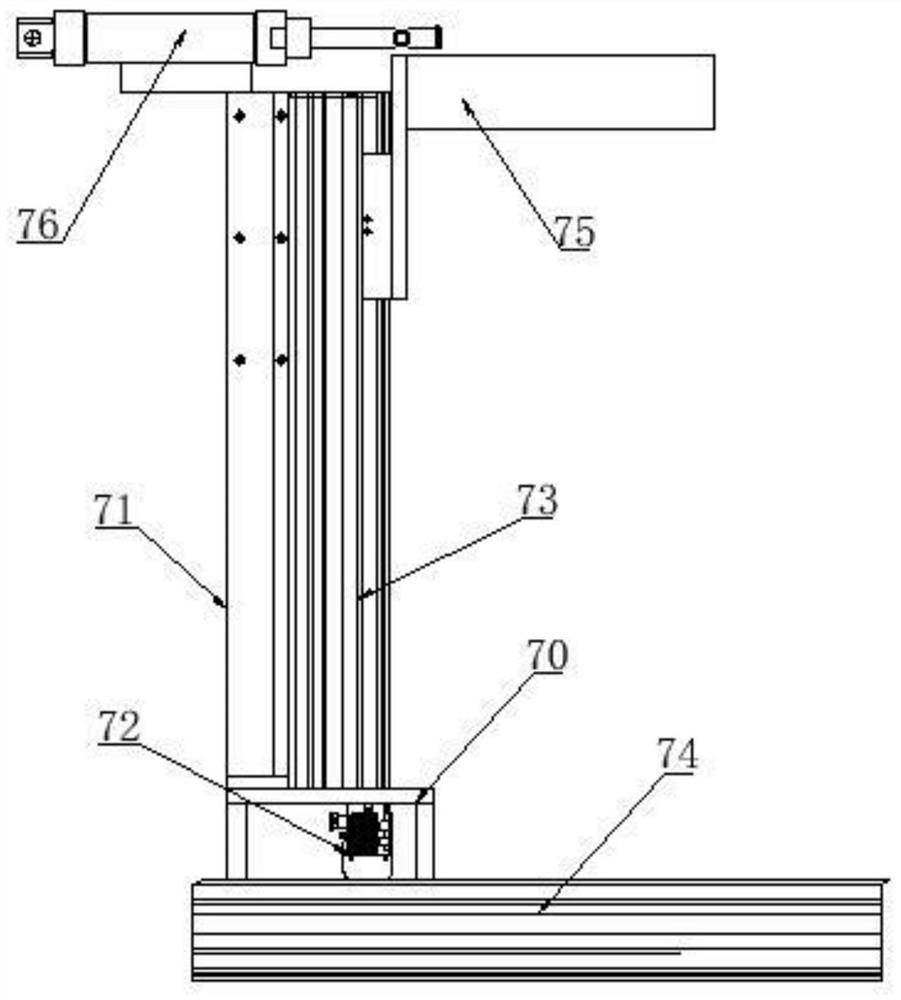

[0026] Such as figure 1 , figure 2 The shown automatic printing and conveying equipment for tempered glass includes a decal furnace 1 and a decal paper roll 2. There are glass racks inside the decal furnace 1, and the distance between each layer of glass racks is equal for placing glass. The glass decals are printed equidistantly on the printing paper roll 2, so as to facilitate the cooperation of the horizontal conveying mechanism for conveying the glass at a constant speed, and the glass decals are accurately pasted on the glass sheets at equal distances in turn. In addition to the existing equipment used above, its automatic printing and conveying equipment also includes a water immersion and deflowering mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com