A laser processing system and method for monitoring changes in laser power

A technology of laser processing and laser power, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of poor laser cutting consistency and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

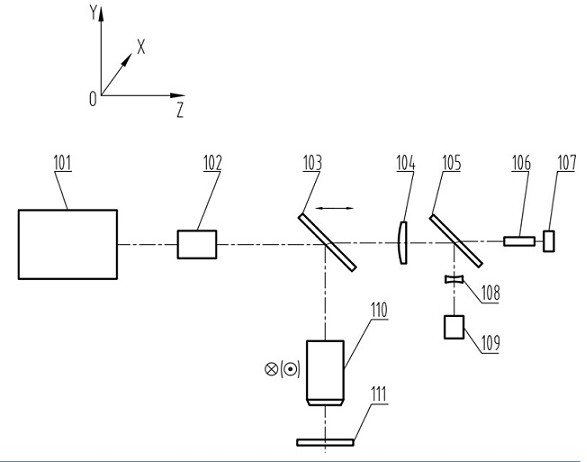

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

[0041] A laser processing system for monitoring changes in laser power and position, including a laser 101, a beam expander 102, a first beam splitter 103, a positive lens 104, a second beam splitter 105, an integrator rod 106, an energy detector 107, Negative lens 108 , PSD detector 109 , laser cutting head 110 and workpiece table 111 .

[0042]PSD Detector: Position Sensitive Detector.

[0043] The laser 101 is a high-power laser: the general power is above 10 watts;

[0044] The laser 101 provides a laser processing light source for the laser processing system, and the laser 101 produces a laser beam with high repetition rate, high peak pulse and narrow line width (high repetition rate: generally above 10KHz; high peak pulse: generally at 0.1mJ above; narrow linewidth: less than or equal to nanosecond linewidth); preferably, the laser is a picosecond laser, or a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com