Laser processing system and method for monitoring laser power changes

A technology of laser processing and laser power, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of poor laser cutting consistency and yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The present invention will be further described below in conjunction with the drawings.

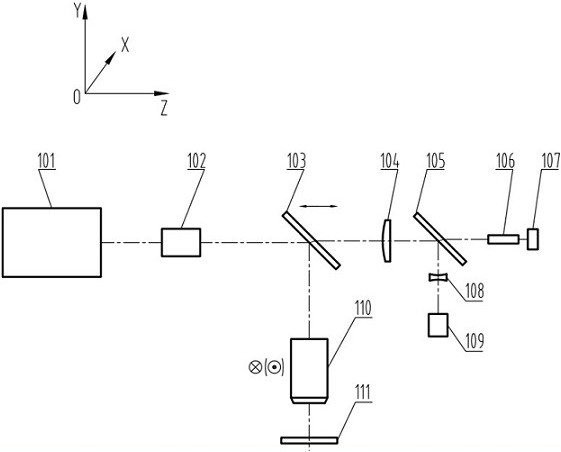

[0041]A laser processing system for monitoring changes in laser power and position, including laser 101, beam expander 102, first beam splitter 103, positive lens 104, second beam splitter 105, integrator 106, energy detector 107, The negative lens 108, the PSD detector 109, the laser cutting head 110 and the workpiece table 111.

[0042]PSD detector: position sensitive detector.

[0043]The laser 101 is a high-power laser: the general power is above 10 watts;

[0044]The laser 101 provides a laser processing light source for a laser processing system. The laser 101 generates a laser beam with high repetition rate, high peak pulses and narrow line width (high repetition frequency: generally above 10KHz; high peak pulse: generally 0.1mJ Above; narrow line width: line width less than or equal to nanoseconds); preferably, the laser is a picosecond laser or a femtosecond laser;

[0045]The beam expander 102...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com