Preparation method of rubidium-doped inorganic-organic lithium battery composite coating type diaphragm

A composite diaphragm and lithium battery technology, which is applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of low ion transmission permeability, affecting lithium ion conductivity, and poor cycle performance, so as to improve safety performance and increase The effect of high electrochemical performance and ionic conductivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A rubidium-doped inorganic-organic lithium battery composite coating separator, with a dry-process single-drawn polyolefin porous diaphragm (thickness 8um, porosity 30%) as the base material, rubidium-doped TiO 2 and polyacrylic acid as the main raw materials are coated on the surface of the base film with a thickness of 12um; the specific preparation method is as follows:

[0031] (1) Prepare the dispersion slurry of the inorganic oxide precursor: add ethyl titanate to a mixed solvent with a volume ratio of ethanol / water of 20:80, mix evenly, and stir for 30 minutes to obtain a relatively uniform colloid, then add RbNO 3 (wherein the mass ratio of inorganic oxide precursor, rubidium salt, and mixed solvent is 5:1:100), adjust the pH by using HCl solution and NaOH solution, when the Zeta potential is 0, continue to drop the HCl solution until the Zeta potential is - 40mV, continue to stir for 30min, then transfer to the reactor for crystallization at 100°C for 12h, mix ...

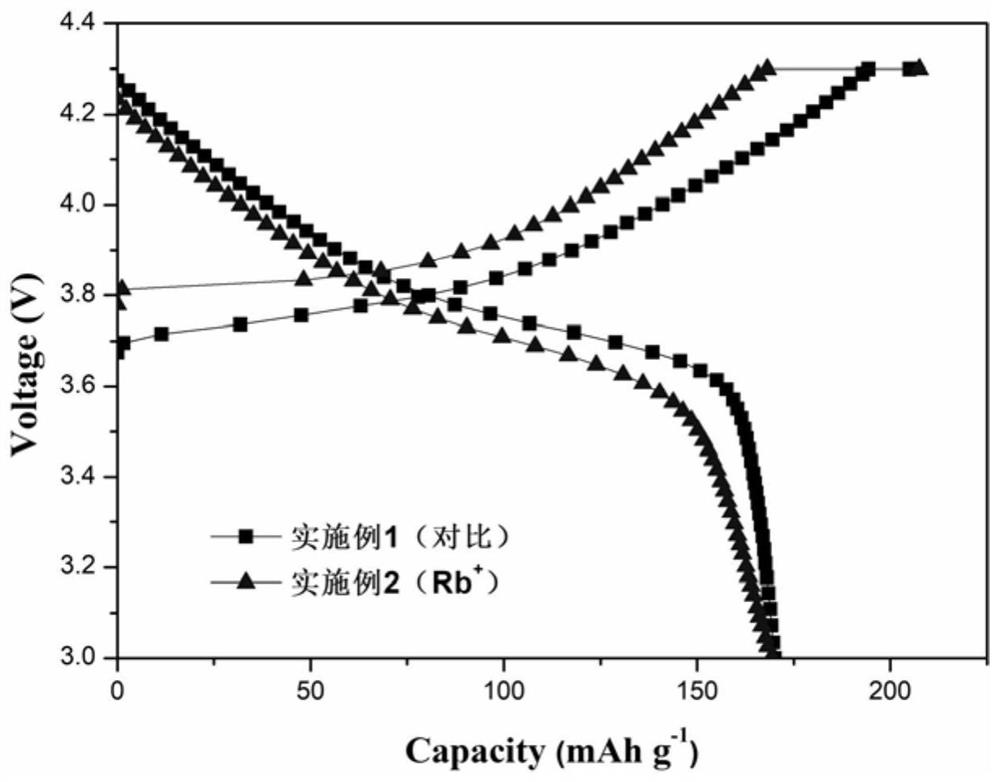

Embodiment 2

[0037] A rubidium-doped inorganic-organic lithium battery composite coating separator, based on a dry-process single-drawn polyolefin porous diaphragm (thickness 10um, porosity 30%), rubidium-doped TiO 2 Coated with polyacrylic acid as the main raw material on the surface of the base film with a thickness of 14um; the specific preparation method is as follows:

[0038] (1) Prepare the dispersion slurry of the inorganic oxide precursor: add ethyl titanate to a mixed solvent with a volume ratio of ethanol / water of 20:80, mix evenly, and stir for 30 minutes to obtain a relatively uniform colloid, then add RbNO 3 (the mass ratio of the inorganic oxide precursor, rubidium salt, and mixed solvent is 5:2:100), adjust the pH by using HCl solution and NaOH solution, when the Zeta potential is 0, continue to drop the HCl solution until the Zeta potential is - 40mV, continue to stir for 30min, then transfer to the reactor for crystallization at 120°C for 12h, mix well and form a colloid ...

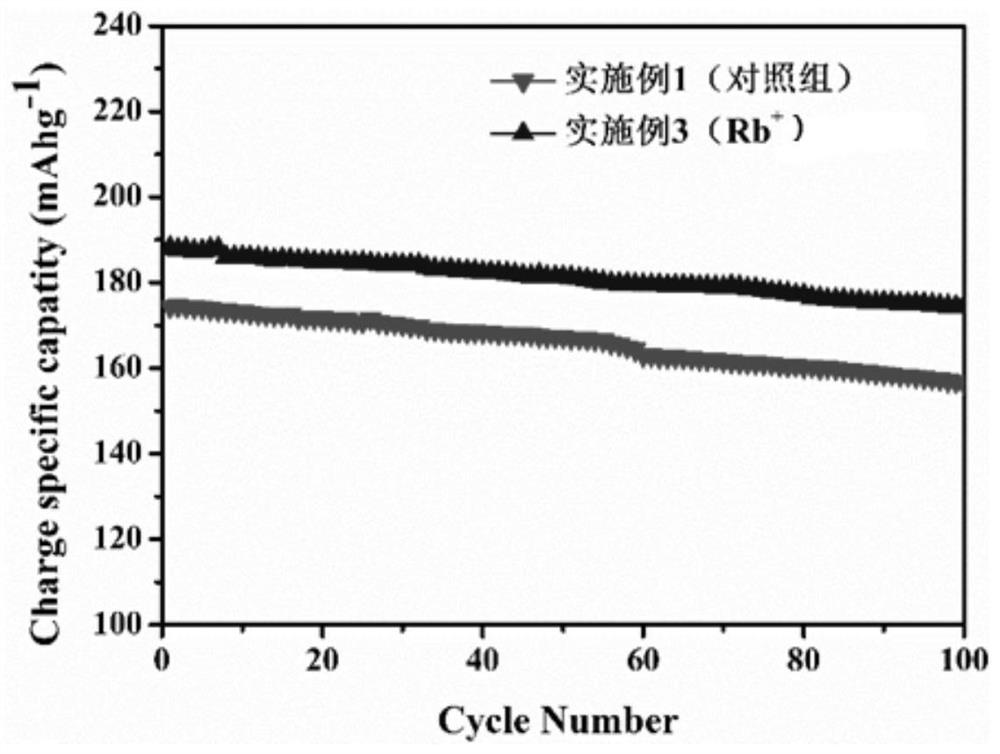

Embodiment 3

[0043] A rubidium-doped inorganic-organic lithium battery composite coating separator, with a dry-process single-drawn polyolefin porous diaphragm (thickness 12um, porosity 30%) as the base material, rubidium-doped TiO 2 Coated with polyacrylic acid as the main raw material on the surface of the base film with a thickness of 15um; the specific preparation method is as follows:

[0044] (1) Prepare the dispersion slurry of the inorganic oxide precursor: add ethyl titanate to a mixed solvent with a volume ratio of ethanol / water of 20:80, mix evenly, and stir for 30 minutes to obtain a relatively uniform colloid, then add RbNO 3 (the mass ratio of the inorganic oxide precursor, rubidium salt, and mixed solvent is 5:5:100), adjust the pH by using HCl solution and NaOH solution, when the Zeta potential is 0, continue to drop the HCl solution until the Zeta potential is - 40mV, continue to stir for 30min, then transfer to the reactor for crystallization at 120°C for 12h, mix well an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com