Solid electrolyte and preparation method and application thereof

A solid electrolyte and halogen atom technology, applied in the field of lithium-ion batteries, can solve problems such as explosion, combustion, and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

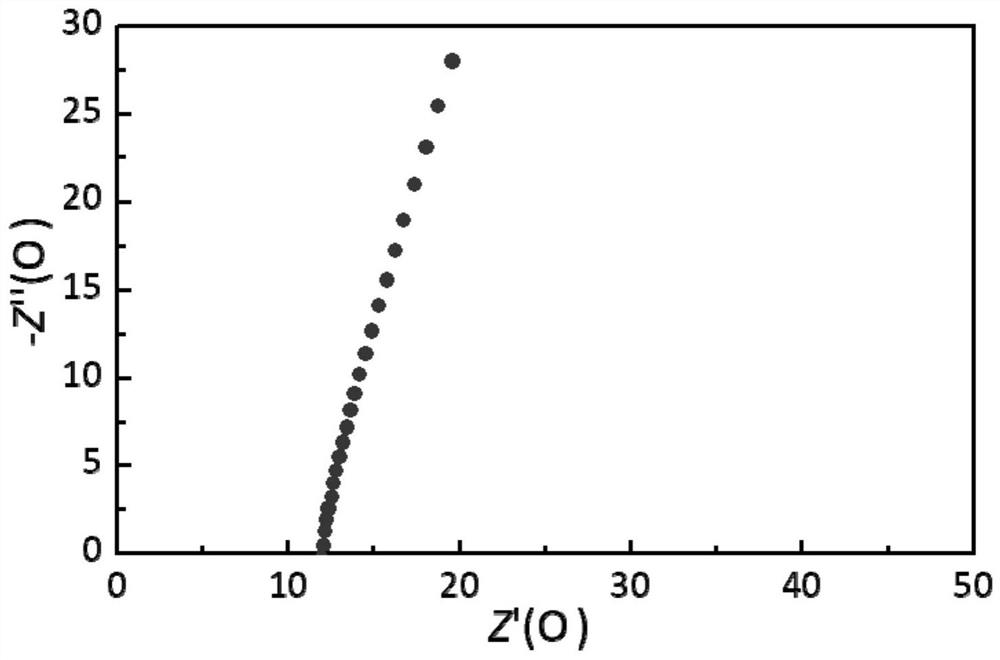

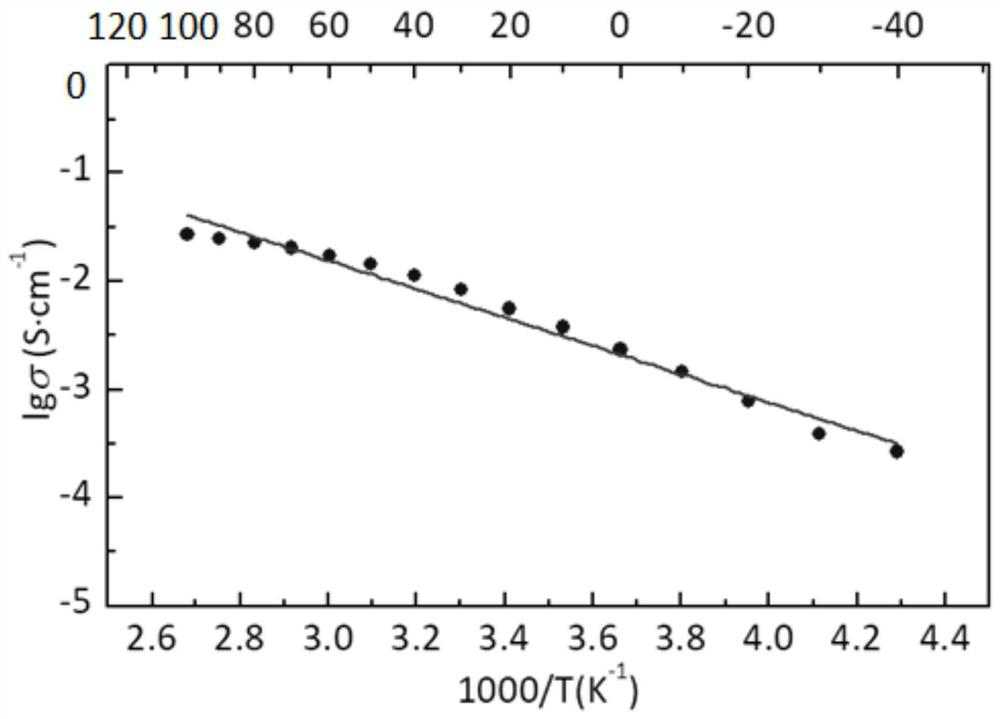

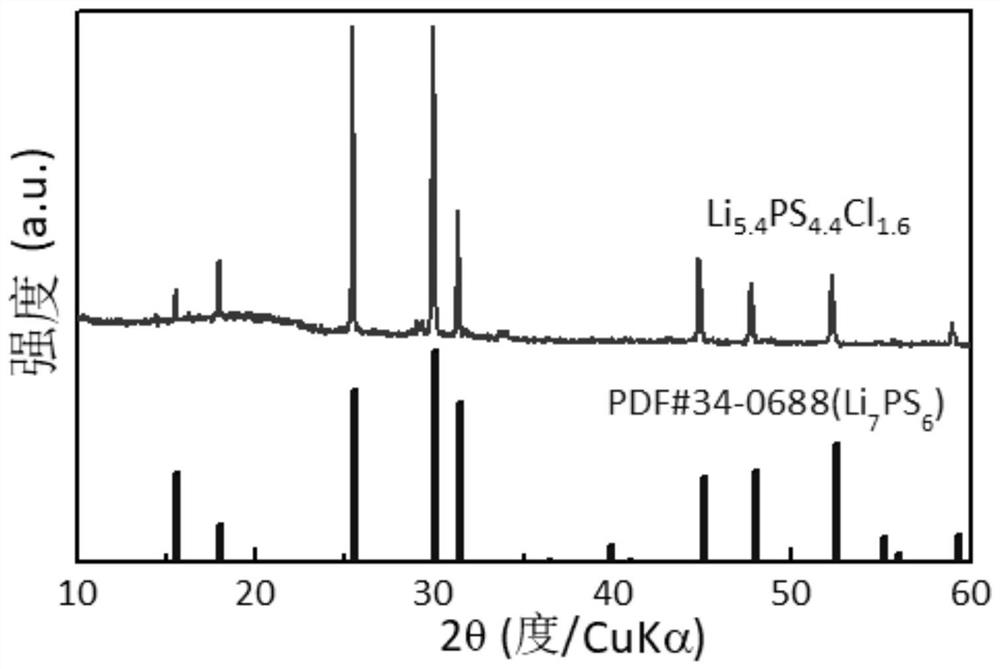

[0058] This embodiment provides a kind of solid electrolyte, and described solid electrolyte is Li 5.4 P.S. 4.4 Cl 1.6 .

[0059] The preparation method of the above-mentioned solid electrolyte comprises the following steps:

[0060] (1) In an argon atmosphere protection, Li with a purity of 99.9% 2 S, P 2 S 5 and LiCl were weighed according to the molar ratio of 47.5:12.5:40, and were ground at 500 rpm for 15 hours by a high-energy ball mill with a ball-to-material mass ratio of 45:1 under the condition that the water content was 9 ppm, and mixed to obtain the first powder;

[0061] (2) Compressing the powder primary material at a pressure of 10MPa to obtain a flake primary material;

[0062] (3) Raise the temperature of the flake raw material to 470°C at a rate of 2°C / min, sinter for 4 hours, cool to room temperature, take out the sintered product and grind it evenly under the condition of water content of 90ppm to obtain Li 5.4 P.S. 4.4 Cl 1.6 .

Embodiment 2

[0064] This embodiment provides a kind of solid electrolyte, and described solid electrolyte is Li 6 P.S. 5 Br.

[0065] The preparation method of the above-mentioned solid electrolyte comprises the following steps:

[0066] (1) In an argon atmosphere protection, Li with a purity of 99.8% 2 S, P 2 S 5 and LiBr were weighed according to the molar ratio of 62.5:12.5:25, and were ground at 500 rpm for 15 hours by a high-energy ball mill with a ball-to-material mass ratio of 45:1 under the condition that the water content was 9 ppm, and mixed to obtain the first powder;

[0067] (2) Compressing the powder primary material at a pressure of 10MPa to obtain a flake primary material;

[0068] (3) Raise the temperature of the flake raw material to 550°C at a rate of 2°C / min, sinter for 4 hours, cool to room temperature, take out the sintered product and grind it evenly under the condition of water content of 90ppm to obtain Li 6 P.S. 5 Br.

Embodiment 3

[0070] This embodiment provides a kind of solid electrolyte, and described solid electrolyte is Li 6.6 P.S. 5.6 f 0.4 .

[0071] The preparation method of the above-mentioned solid electrolyte comprises the following steps:

[0072] (1) In an argon atmosphere protection, Li with a purity of 99.7% 2 S, P 2 S 5 Weigh with LiF according to the molar ratio of 77.5:12.5:10, and grind at 500rpm for 15h by a high-energy ball mill with a mass ratio of ball to material of 45:1 under the condition that the water content is 9ppm, and mix to obtain the first powder;

[0073] (2) Compressing the powder primary material at a pressure of 10MPa to obtain a flake primary material;

[0074] (3) Raise the temperature of the flake raw material to 520°C at a rate of 2°C / min, sinter for 4 hours, cool to room temperature, take out the sintered product and grind it evenly under the condition of water content of 90ppm to obtain Li 6.6 P.S. 5.6 f 0.4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Li-ion conductivity | aaaaa | aaaaa |

| Li-ion conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com