Machine vision soap bubble method air tightness test method

An inspection method, soap bubble technology, applied in liquid/vacuum measurement for liquid tightness, by detecting the appearance of fluid at the leak point, etc., it can solve the problem of leak point falling off, only deformed bubbles can be observed, machine vision recognition Difficulty in locating bubbles and leaks, to prevent missed detection and false detection, reduce professional skills requirements, and reduce professional skills requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention is further analyzed below in conjunction with specific examples.

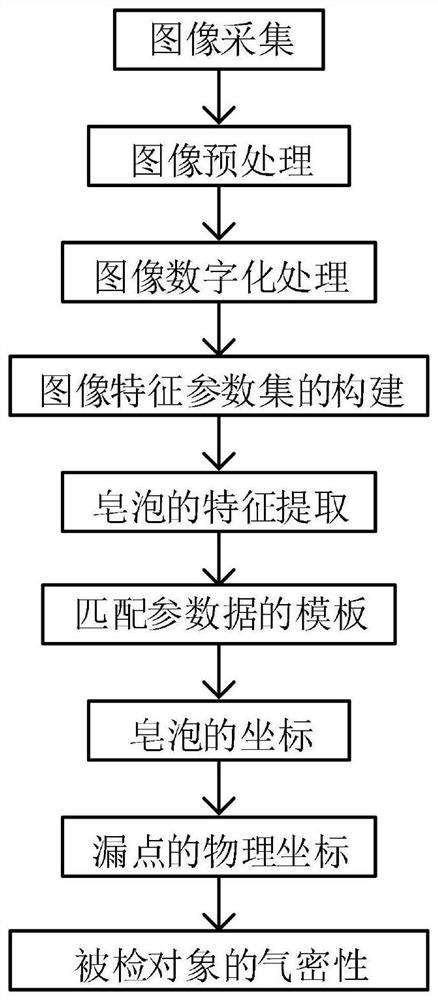

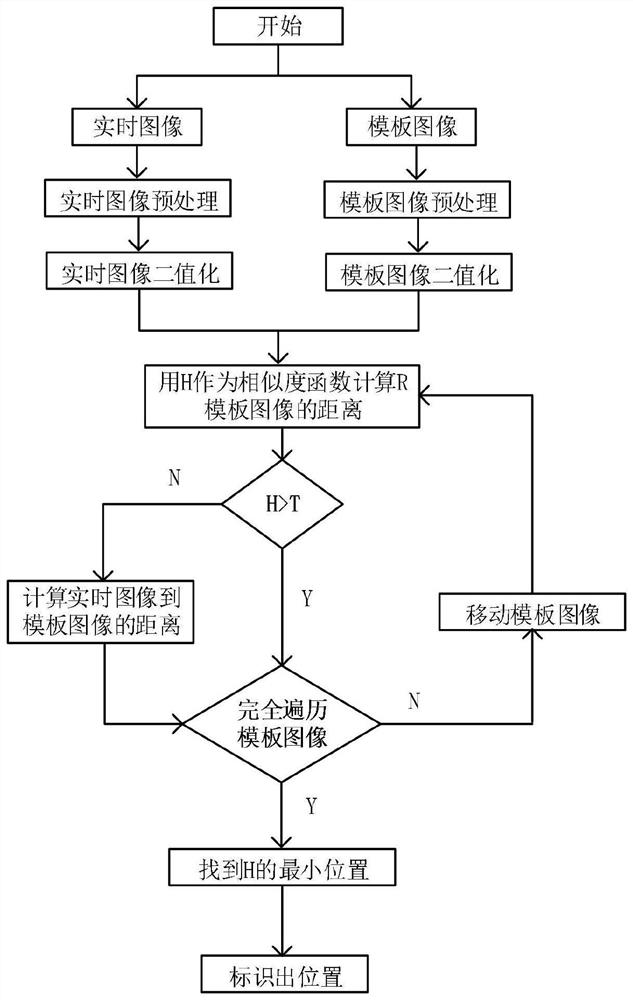

[0047] like figure 1 and 2 As shown, a machine vision air tightness inspection method is specifically implemented as follows:

[0048] Step (1) Gas filling

[0049] Fill the device under test with a certain positive pressure of gas.

[0050] Step (2) Soap solution brushing:

[0051] Select the soap concentration and brushing method according to the size of the object to be inspected, and apply the soap liquid evenly on the surface of the object to be inspected;

[0052] Step (3) optical lighting:

[0053] After the soap is painted, after the soap grows for a specified time, the optical lighting components need to be turned on before the industrial camera takes pictures;

[0054] Step (4) Photo shooting:

[0055] If the size of the inspected object is larger than the set size threshold, limited by the resolution of the CCD camera, all the information of the inspected object ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com