EGR gas-assisted aviation kerosene injection system

A gas-assisted, aviation kerosene technology, applied in the charging system, fuel injection device, exhaust gas recirculation and other directions, can solve the problems of slow flame propagation, knocking, and the spark plug is easy to flood the cylinder, so as to improve the atomization quality and promote The effect of fuel atomization and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

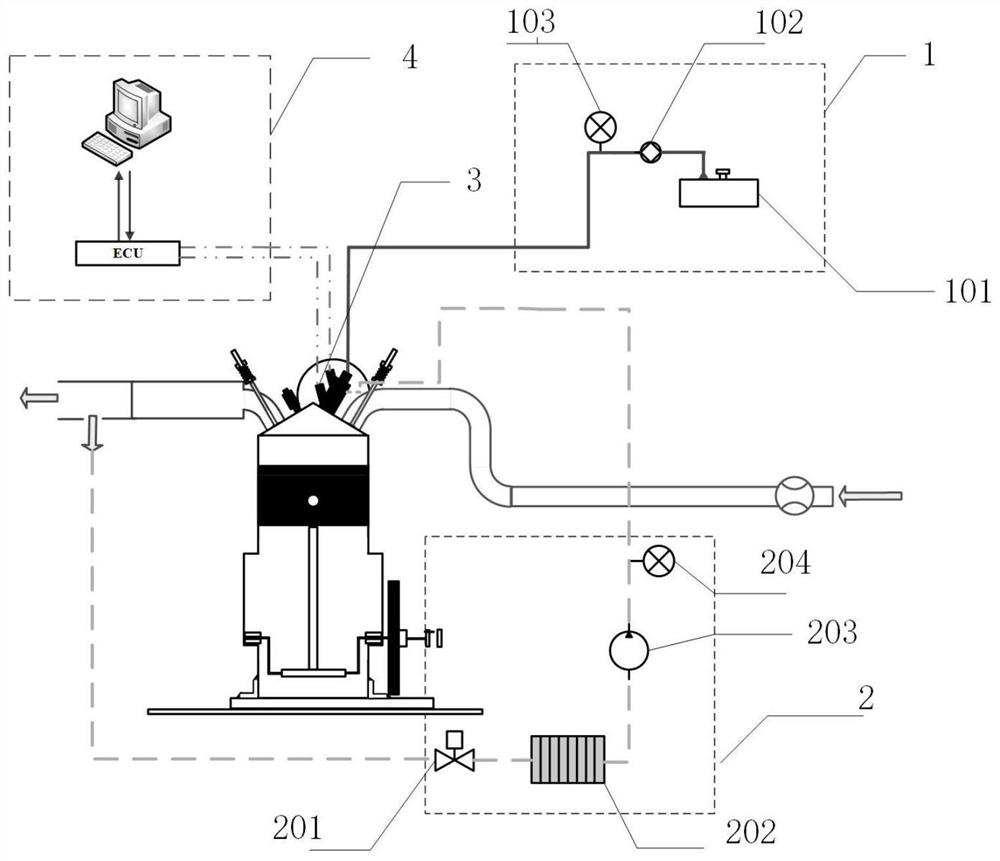

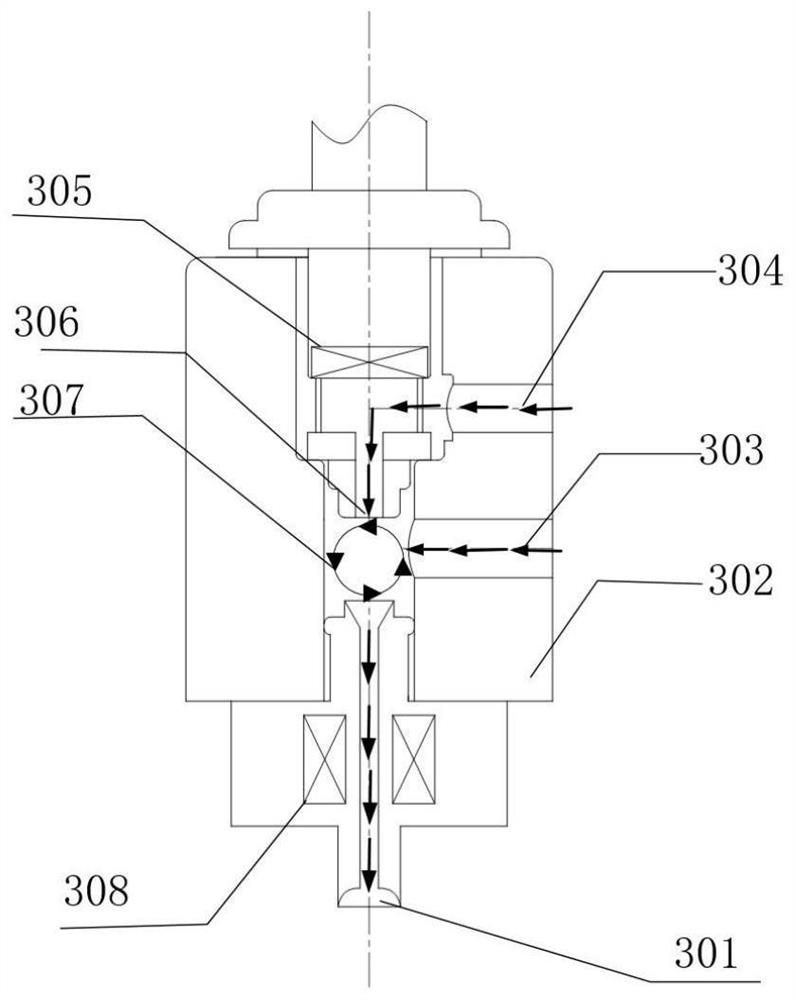

[0014] as attached figure 1 As shown, the present invention includes a fuel supply system 1 , an EGR system 2 , a gas-assisted fuel injector 3 , and an ECU control system 4 . The EGR system 2 is connected to the gas-assisted injector 3 through an air pipeline, and the fuel supply system 1 is connected to the gas-assisted injector 3 through an oil pipeline. The fuel supply system 1 pressurizes aviation kerosene from the fuel tank 101 through the low-pressure oil pump 102 , adjusts the pressure through the oil pressure gauge 103 , and finally introduces 8 bar of aviation kerosene into the fuel inlet 304 of the gas-assisted injector 3 . The EGR gas discharged after the engine works is controlled by the EGR valve 201 in the EGR system 2, and then the EGR gas is cooled by the intercooler 202, and the compressor 203 increases the pressure of the EGR gas to reach the gas-assisted injection system. Requirements, the pressure is regulated by the pressure gauge 204, and finally the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com