Preparation method of fiber mesh-compounded diatom ooze coating

A technology of diatom mud coating and fiber screen, which is applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of inconvenient construction and low strength, and achieve reduced molding time and heat conduction The effect of good sex and good bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

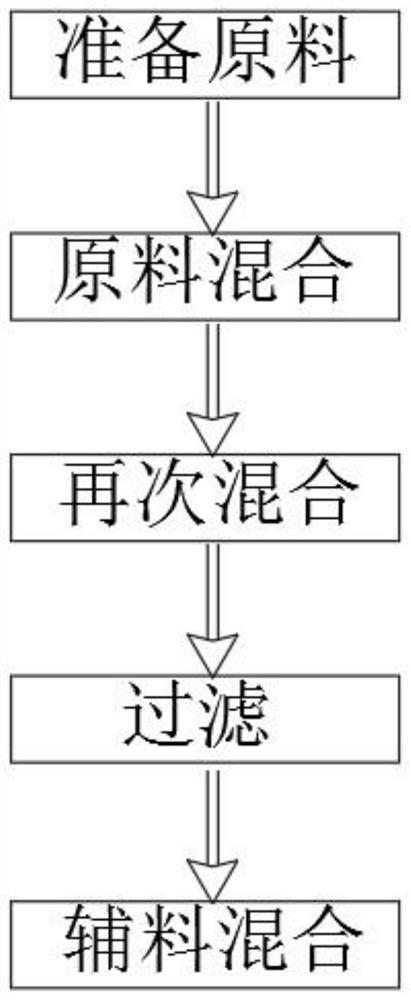

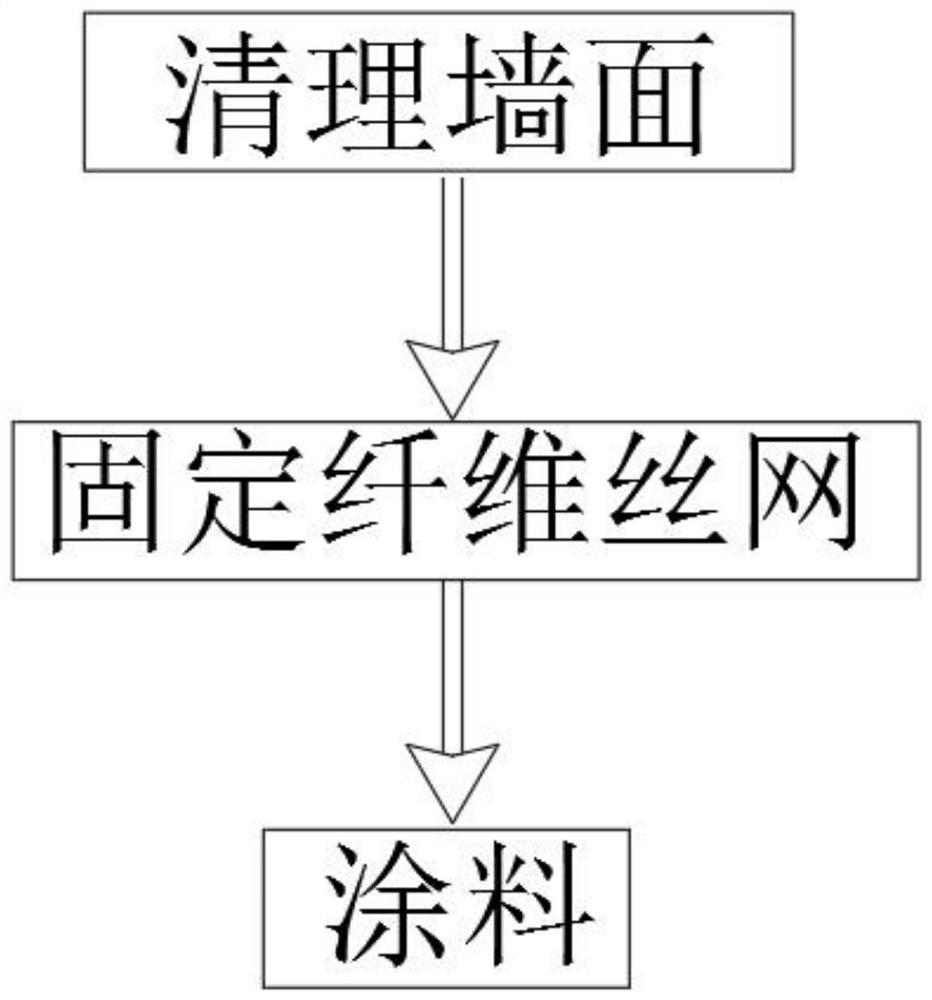

[0034] refer to Figure 1-2 , a kind of preparation method of fiber screen composite diatom mud coating, comprises the following steps:

[0035] S1: Prepare raw materials, fiber screen, 25-35 parts of deionized water, 15-25 parts of diatomaceous earth, 2-8 parts of humectant, 15-25 parts of pure benzene deodorant emulsion, 10-18 parts of filler, quartz powder 2-6 parts, 0.5-1 part of dispersant, 0.5-1 part of defoamer, 0.2-1 part of nano-diamond particles, 0.2-0.8 part of leveling agent, 0.3-0.6 part of thickener, 2-5 parts of antifreeze , 3-7 parts of photocatalyst, 2-5 parts of antifungal agent; the main material of the present invention is diatomite, which has the characteristics of large porosity, strong absorption, stable chemical properties, heat resistance, etc., and can provide coatings with Excellent surface properties, compatibilization, thickening and improved adhesion. Diatomite coating also has the function of eliminating odor and keeping the room clean. Nano-dia...

Embodiment 2

[0048] refer to Figure 1-2 , a kind of preparation method of fiber screen composite diatom mud coating, comprises the following steps:

[0049] S1: Prepare raw materials, fiber screen, 28-40 parts of deionized water, 18-25 parts of diatomaceous earth, 2-8 parts of humectant, 17-25 parts of pure benzene deodorant emulsion, 13-18 parts of filler, quartz powder 3-6 parts, 0.5-1 part of dispersant, 0.5-1 part of defoamer, 0.5-1 part of nano-diamond particles, 0.2-0.8 part of leveling agent, 0.3-0.6 part of thickener, 2-4 parts of antifreeze , 3-7 parts of photocatalyst, 2-5 parts of antifungal agent; the main material of the present invention is diatomite, which has the characteristics of large porosity, strong absorption, stable chemical properties, heat resistance, etc., and can provide coatings with Excellent surface properties, compatibilization, thickening and improved adhesion. Diatomite coating also has the function of eliminating odor and keeping the room clean. Nano-dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com