Production device and method of delta-caprolactone synthetic perfume

A technology for synthesizing fragrances and production methods, applied in chemical instruments and methods, sustainable manufacturing/processing, chemical industry, etc., can solve problems such as high cost, low yield of δ-caprolactone synthesis, complex process, etc., to achieve Effects of reducing waste, improving production efficiency, and increasing reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

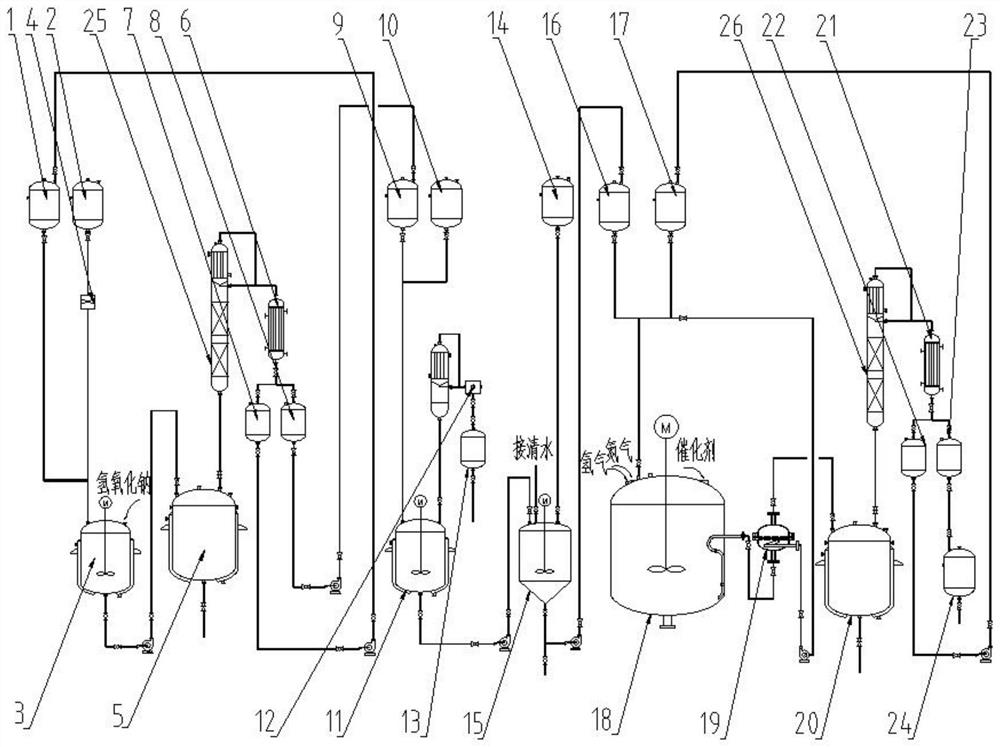

Image

Examples

Embodiment 1

[0031] A kind of production method of delta-caprolactone synthetic perfume, specifically comprises the following steps:

[0032] Step S1, open the circulating cooling water and agitator of the reaction kettle 3 of the fragrance production device, add 300 kg of ethyl acetoacetate from the ethyl acetoacetate header tank 1 to the reaction kettle 3, and then add 3 kg of sodium hydroxide to the reaction kettle 3 , stir evenly; open the steam valve of reactor 3, heat up reactor 3, control the temperature of the kettle at 35°C, then add 90kg of methyl acrylate dropwise from methyl acrylate head tank 2 through dripping pump 4 to reactor 3, drop Adding time is controlled at 5.5h. After the dropwise addition, keep the kettle temperature and stir for 1h, take a sample for gas chromatography detection, when the ethyl acetoacetate content is below 1%, the reaction is terminated, and the reaction solution is transferred to the still 5;

[0033] Step S2, open the steam valve of the still 5, ...

Embodiment 2

[0044] A kind of production method of delta-caprolactone synthetic perfume, specifically comprises the following steps:

[0045] Step S1, open the circulating cooling water and the agitator of the reaction kettle 3 of the fragrance production device, add 500 kg of ethyl acetoacetate from the ethyl acetoacetate header tank 1 to the reaction kettle 3, and then add 8 kg of sodium hydroxide to the reaction kettle 3 , stir evenly; open the steam valve of reactor 3, heat up reactor 3, control the temperature of the kettle at 45°C, then add 150kg of methyl acrylate dropwise from methyl acrylate head tank 2 through dripping pump 4 to reactor 3, drop Adding time is controlled at 8h. After the dropwise addition, keep the kettle temperature and stir for 1h, take a sample for gas chromatography detection, when the ethyl acetoacetate content is below 1%, the reaction is terminated, and the reaction solution is transferred to the still 5;

[0046] Step S2, open the steam valve of the still ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com